“Procedural voronoi foams for additive manufacturing”

Conference:

Type(s):

Title:

- Procedural voronoi foams for additive manufacturing

Session/Category Title: FABRICATING STRUCTURE & APPEARANCE

Presenter(s)/Author(s):

Moderator(s):

Abstract:

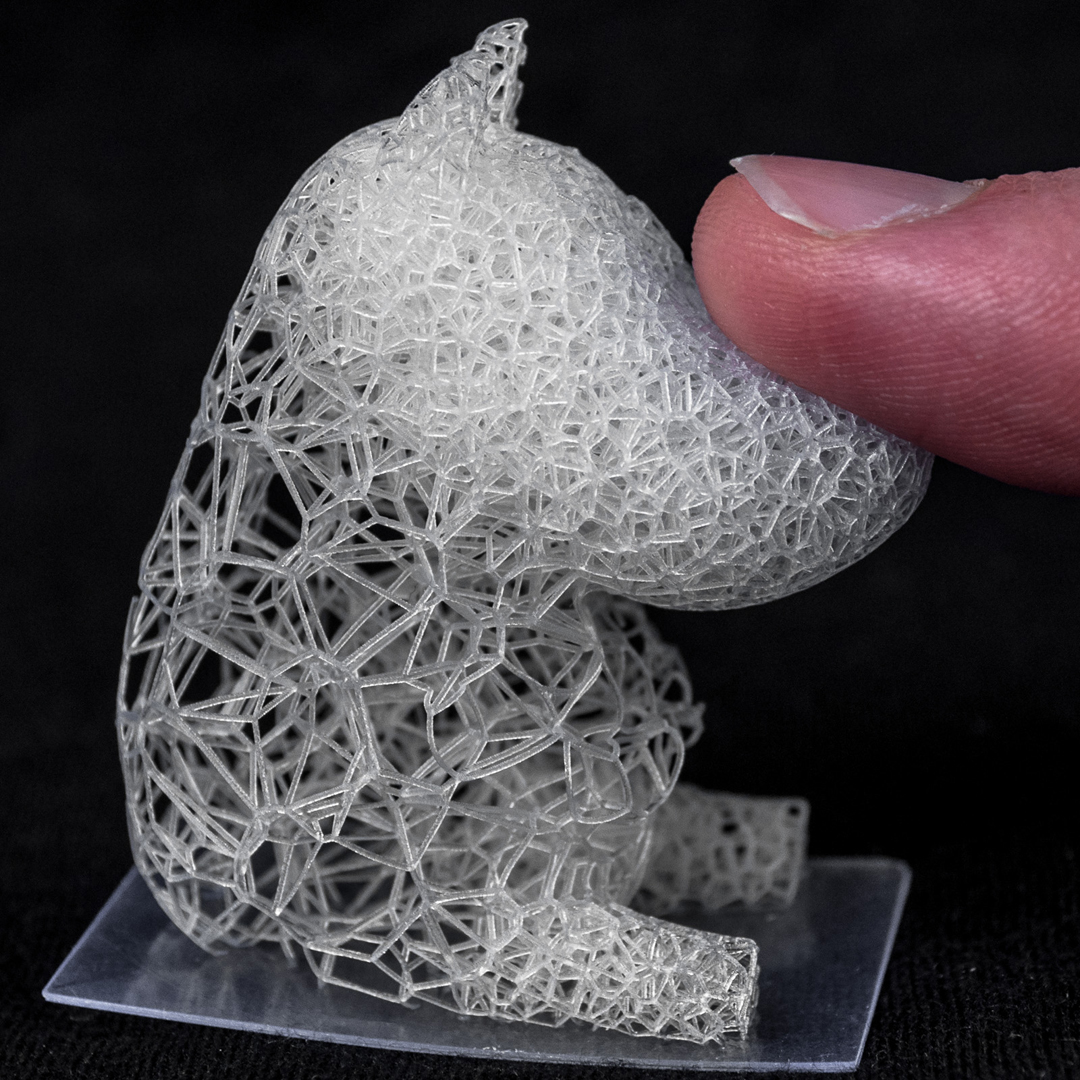

Microstructures at the scale of tens of microns change the physical properties of objects, making them lighter or more flexible. While traditionally difficult to produce, additive manufacturing now lets us physically realize such microstructures at low cost.In this paper we propose to study procedural, aperiodic microstructures inspired by Voronoi open-cell foams. The absence of regularity affords for a simple approach to grade the foam geometry — and thus its mechanical properties — within a target object and its surface. Rather than requiring a global optimization process, the microstructures are directly generated to exhibit a specified elastic behavior. The implicit evaluation is akin to procedural textures in computer graphics, and locally adapts to follow the elasticity field. This allows very detailed structures to be generated in large objects without having to explicitly produce a full representation — mesh or voxels — of the complete object: the structures are added on the fly, just before each object slice is manufactured.We study the elastic behavior of the microstructures and provide a complete description of the procedure generating them. We explain how to determine the geometric parameters of the microstructures from a target elasticity, and evaluate the result on printed samples. Finally, we apply our approach to the fabrication of objects with spatially varying elasticity, including the implicit modeling of a frame following the object surface and seamlessly connecting to the microstructures.

References:

1. Allaire, G. 2012. Shape optimization by the homogenization method, vol. 146. Springer Science & Business Media.Google Scholar

2. Andreassen, E., Lazarov, B. S., and Sigmund, O. 2014. Design of manufacturable 3D extremal elastic microstructure. Mechanics of Materials 69, 1, 1–10.Google ScholarCross Ref

3. Autodesk, 2016. www.autodesk.com/products/within.Google Scholar

4. Bächer, M., Whiting, E., Bickel, B., and Sorkine-Hornung, O. 2014. Spin-it: Optimizing moment of inertia for spinnable objects. ACM Trans. Graph. 33, 4. Google ScholarDigital Library

5. Bickel, B., Bächer, M., Otaduy, M. A., Lee, H. R., Pfister, H., Gross, M., and Matusik, W. 2010. Design and fabrication of materials with desired deformation behavior. ACM Trans. Graph. 29, 4, 63:1–63:10. Google ScholarDigital Library

6. Brackett, D., Ashcroft, I., Wildman, R., and Hague, R. 2014. An error diffusion based method to generate functionally graded cellular structures. Computers & Structures 138, 102–111.Google ScholarCross Ref

7. Brennan-Craddock, J. 2011. The investigation of a method to generate conformal lattice structures for additive manufacturing. PhD thesis, Loughborough University.Google Scholar

8. Cook, R. L. 1986. Stochastic Sampling in Computer Graphics. ACM Trans. Graph. 5, 1, 51–72. Google ScholarDigital Library

9. Fryazinov, O., Vilbrandt, T., and Pasko, A. A. 2013. Multi-scale space-variant FRep cellular structures. Computer-Aided Design 45, 1, 26–34. Google ScholarDigital Library

10. Gaitanaros, S., Kyriakides, S., and Kraynik, A. M. 2012. On the crushing response of random open-cell foams. Int. J. Solids Struct. 49, 19-20, 2733–2743.Google ScholarCross Ref

11. Gibson, L. J., and Ashby, M. F. 1997. Cellular solids: structure and properties. Cambridge university press.Google Scholar

12. Johnson, S. G., 2007. The NLopt nonlinear-optimization package.Google Scholar

13. Lagae, A., Lefebvre, S., Drettakis, G., and Dutré, P. 2009. Procedural noise using sparse Gabor convolution. ACM Trans. Graph. 28, 3, 54:1–54:10. Google ScholarDigital Library

14. Lagae, A., Lefebvre, S., Cook, R., DeRose, T., Drettakis, G., Ebert, D., Lewis, J., Perlin, K., and Zwicker, M. 2010. A survey of procedural noise functions. Computer Graphics Forum 29, 8.Google ScholarCross Ref

15. Li, D., Dai, N., Jiang, X., and Chen, X. 2015. Interior structural optimization based on the density-variable shape modeling of 3D printed objects. The International Journal of Advanced Manufacturing Technology 83, 9.Google Scholar

16. Lu, L., Sharf, A., Zhao, H., Wei, Y., Fan, Q., Chen, X., Savoye, Y., Tu, C., Cohen-Or, D., and Chen, B. 2014. Build-to-last: Strength to weight 3D printed objects. ACM Trans. Graph. 33, 4, 97:1–97:10. Google ScholarDigital Library

17. Luxner, M. H., Stampfl, J., and Pettermann, H. E. 2007. Numerical simulations of 3D open cell structures — influence of structural irregularities on elasto-plasticity and deformation localization. International Journal of Solids and Structures 44, 9, 2990–3003.Google ScholarCross Ref

18. Medeiros e Sá, A., Mello, V. M., Echavarria, K. R., and Covill, D. 2015. Adaptive voids. The Visual Computer 31, 6-8, 799–808. Google ScholarDigital Library

19. Panetta, J., Zhou, Q., Malomo, L., Pietroni, N., Cignoni, P., and Zorin, D. 2015. Elastic textures for additive fabrication. ACM Trans. Graph. 34, 4. Google ScholarDigital Library

20. Pasko, A., Fryazinov, O., Vilbrandt, T., Fayolle, P.-A., and Adzhiev, V. 2011. Procedural function-based modelling of volumetric microstructures. Graphical Models 73, 5, 165–181. Google ScholarDigital Library

21. Pérez, J., Thomaszewski, B., Coros, S., Bickel, B., Canabal, J. A., Sumner, R., and Otaduy, M. A. 2015. Design and fabrication of flexible rod meshes. ACM Trans. Graph. 34, 4, 138:1–138:12. Google ScholarDigital Library

22. Prévost, R., Whiting, E., Lefebvre, S., and Sorkine-Hornung, O. 2013. Make it stand: Balancing shapes for 3D fabrication. ACM Trans. Graph. 32, 4, 81:1–81:10. Google ScholarDigital Library

23. Radman, A., Huang, X., and Xie, Y. 2013. Topology optimization of functionally graded cellular materials. Journal of Materials Science 48, 4, 1503–1510.Google ScholarCross Ref

24. Roberts, A., and Garboczi, E. 2002. Elastic properties of model random three-dimensional open-cell solids. Journal of the Mechanics and Physics of Solids 50, 1, 33–55.Google ScholarCross Ref

25. Schumacher, C., Bickel, B., Rys, J., Marschner, S., Daraio, C., and Gross, M. 2015. Microstructures to control elasticity in 3D printing. ACM Trans. Graph. 34, 4, 136:1–136:13. Google ScholarDigital Library

26. Sigmund, O., and Torquato, S. 1999. Design of smart composite materials using topology optimization. Smart Materials and Structures 8, 3, 365.Google ScholarCross Ref

27. Sigmund, O. 1994. Materials with prescribed constitutive parameters: An inverse homogenization problem. Int. J. Solids Struct. 31, 17, 2313–2329.Google ScholarCross Ref

28. Sigmund, O. 1995. Tailoring materials with prescribed elastic properties. Mechanics of Materials 20, 4, 351–368.Google ScholarCross Ref

29. Skouras, M., Thomaszewski, B., Coros, S., Bickel, B., and Gross, M. 2013. Computational design of actuated deformable characters. ACM Trans. Graph. 32, 4. Google ScholarDigital Library

30. Staten, M. L. 2007. Why is hex meshing so hard? Presentation at Sandia National Laboratories (URL).Google Scholar

31. Stava, O., Vanek, J., Benes, B., Carr, N., and Měch, R. 2012. Stress relief: Improving structural strength of 3D printable objects. ACM Trans. Graph. 31, 4, 48:1–48:11. Google ScholarDigital Library

32. Umetani, N., and Schmidt, R. 2013. Cross-sectional structural analysis for 3D printing optimization. In SIGGRAPH Asia 2013 Technical Briefs, 5:1–5:4. Google ScholarDigital Library

33. Van Der Burg, M. W. D., Shulmeister, V., Van Der Geissen, E., and Marissen, R. 1997. On the linear elastic properties of regular and random open-cell foam models. Journal of Cellular Plastics 33, 1, 31–54.Google ScholarCross Ref

34. Vidimče, K., Wang, S.-P., Ragan-Kelley, J., and Matusik, W. 2013. OpenFab: A programmable pipeline for multi-material fabrication. ACM Trans. Graph. 32, 4, 136:1–136:12. Google ScholarDigital Library

35. Wang, W., Wang, T. Y., Yang, Z., Liu, L., Tong, X., Tong, W., Deng, J., Chen, F., and Liu, X. 2013. Cost-effective printing of 3D objects with skin-frame structures. ACM Trans. Graph. 32, 6, 177:1–177:10. Google ScholarDigital Library

36. Worley, S. P. 1996. A cellular texturing basis function. In Proceedings of SIGGRAPH, 291–294. Google ScholarDigital Library

37. Xia, L., and Breitkopf, P. 2015. Design of materials using topology optimization and energy-based homogenization approach in Matlab. Struct. Multidiscip. Opt. 52, 6. Google ScholarDigital Library

38. Xu, H., Li, Y., Chen, Y., and Barbič, J. 2015. Interactive material design using model reduction. ACM Trans. Graph. 34, 2, 18:1–18:14. Google ScholarDigital Library

39. Zhou, S., and Li, Q. 2008. Design of graded two-phase microstructures for tailored elasticity gradients. Journal of Materials Science 43, 15, 5157–5167.Google ScholarCross Ref

40. Zhou, Q., Panetta, J., and Zorin, D. 2013. Worst-case structural analysis. ACM Trans. Graph. 32, 4, 137:1–137:12. Google ScholarDigital Library