“Lightweight structure design under force location uncertainty” by Ulu, McCann and Kara

Conference:

Type(s):

Title:

- Lightweight structure design under force location uncertainty

Session/Category Title:

- Work it, Make it Better, Stronger

Presenter(s)/Author(s):

Moderator(s):

Abstract:

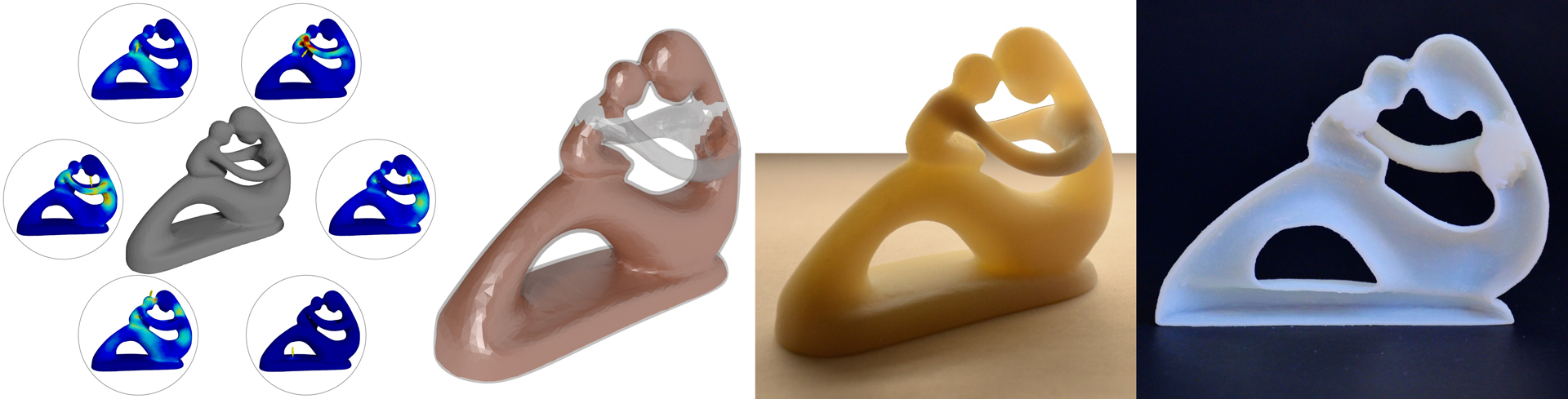

We introduce a lightweight structure optimization approach for problems in which there is uncertainty in the force locations. Such uncertainty may arise due to force contact locations that change during use or are simply unknown a priori. Given an input 3D model, regions on its boundary where arbitrary normal forces may make contact, and a total force-magnitude budget, our algorithm generates a minimum weight 3D structure that withstands any force configuration capped by the budget. Our approach works by repeatedly finding the most critical force configuration and altering the internal structure accordingly. A key issue, however, is that the critical force configuration changes as the structure evolves, resulting in a significant computational challenge. To address this, we propose an efficient critical instant analysis approach. Combined with a reduced order formulation, our method provides a practical solution to the structural optimization problem. We demonstrate our method on a variety of models and validate it with mechanical tests.

References:

1. Moritz Bächer, Emily Whiting, Bernd Bickel, and Olga Sorkine-Hornung. 2014. Spin-it: Optimizing Moment of Inertia for Spinnable Objects. ACM Trans. Graph. 33, 4, Article 96 (July 2014), 10 pages. Google ScholarDigital Library

2. Nikolai Vladimirovich Banichuk. 2013. Introduction to optimization of structures. Springer Science & Business Media.Google Scholar

3. Martin P. Bendsøe. 1989. Optimal shape design as a material distribution problem. Structural optimization 1, 4 (1989), 193–202. Google ScholarCross Ref

4. Martin P. Bendsøe and Ole Sigmund. 2003. Topology optimization: theory, methods, and applications. Springer-Verlag.Google Scholar

5. Bernd Bickel, Moritz Bächer, Miguel A. Otaduy, Hyunho Richard Lee, Hanspeter Pfister, Markus Gross, and Wojciech Matusik. 2010. Design and Fabrication of Materials with Desired Deformation Behavior. ACM Trans. Graph. 29, 4, Article 63 (July 2010), 10 pages. Google ScholarDigital Library

6. Desai Chen, David I. W. Levin, Piotr Didyk, Pitchaya Sitthi-Amorn, and Wojciech Matusik. 2013. Spec2Fab: A reducer-tuner model for translating specifications to 3D prints. ACM Transactions on Graphics (Proceedings SIGGRAPH2013, Anaheim, CA) 32, 4 (2013), 135:1–135:10.Google ScholarDigital Library

7. Woo-Seok Choi and Gyung-Jin Park. 2002. Structural optimization using equivalent static loads at all time intervals. Computer Methods in Applied Mechanics and Engineering 191, 19âĂŞ20 (2002), 2105 — 2122. Google ScholarCross Ref

8. Asger Nyman Christiansen, J. Andreas Bærentzen, Morten Nobel-Jørgensen, Niels Aage, and Ole Sigmund. 2015. Combined Shape and Topology Optimization of 3D Structures. Comput. Graph. 46, C (Feb. 2015), 25–35. Google ScholarDigital Library

9. Keenan Crane, Clarisse Weischedel, and Max Wardetzky. 2013. Geodesics in Heat: A New Approach to Computing Distance Based on Heat Flow. ACM Trans. Graph. 32 (2013). Issue 5.Google Scholar

10. GaËl Guennebaud, Benoît Jacob, and others. 2010. Eigen v3. http://eigen.tuxfamily.org. (2010).Google Scholar

11. Russell C. Hibbeler and Tan Kiang. 2015. Structural analysis. Prentice Hall.Google Scholar

12. Ming-Hsiu Hsu and Yeh-Liang Hsu. 2005. Interpreting three-dimensional structural topology optimization results. Computers & structures 83, 4 (2005), 327–337. Google ScholarDigital Library

13. Uri Kirsch. 1990. On singular topologies in optimum structural design. Structural and Multidisciplinary Optimization 2, 3 (1990), 133–142. Google ScholarCross Ref

14. Timothy Langlois, Ariel Shamir, Daniel Dror, Wojciech Matusik, and David I. W. Levin. 2016. Stochastic Structural Analysis for Context-aware Design and Fabrication. ACM Trans. Graph. 35, 6, Article 226 (Nov. 2016), 13 pages. Google ScholarDigital Library

15. Edmund Lee, Kai A. James, and Joaquim R. R. A. Martins. 2012. Stress-constrained topology optimization with design-dependent loading. Structural and Multidisciplinary Optimization 46, 5 (2012), 647–661. Google ScholarDigital Library

16. Richard B. Lehoucq, Danny C. Sorensen, and Chao Yang. 1998. ARPACK users’ guide: solution of large-scale eigenvalue problems with implicitly restarted Arnoldi methods. Vol. 6. Siam. Google ScholarCross Ref

17. Lin Lu, Andrei Sharf, Haisen Zhao, Yuan Wei, Qingnan Fan, Xuelin Chen, Yann Savoye, Changhe Tu, Daniel Cohen-Or, and Baoquan Chen. 2014. Build-to-last: Strength to Weight 3D Printed Objects. ACM Trans. Graph. 33, 4, Article 97 (July 2014), 10 pages. Google ScholarDigital Library

18. Asla Medeiros E Sá, Vinícius Moreira Mello, Karina Rodriguez Echavarria, and Derek Covill. 2015. Adaptive Voids. Vis. Comput. 31, 6–8 (June 2015), 799–808. Google ScholarDigital Library

19. Przemyslaw Musialski, Thomas Auzinger, Michael Birsak, Michael Wimmer, and Leif Kobbelt. 2015. Reduced-order Shape Optimization Using Offset Surfaces. ACM Trans. Graph. 34, 4, Article 102 (July 2015), 9 pages. Google ScholarDigital Library

20. Jorge Nocedal and Stephen J. Wright. 2006. Numerical Optimization, Second Edition. Springer.Google Scholar

21. Julian Panetta, Qingnan Zhou, Luigi Malomo, Nico Pietroni, Paolo Cignoni, and Denis Zorin. 2015. Elastic Textures for Additive Fabrication. ACM Trans. Graph. 34, 4, Article 135 (July 2015), 12 pages. Google ScholarDigital Library

22. Jose Paris, Fermin Navarrina, Ignasi Colominas, and Manuel Casteleiro. 2010. Stress constraints sensitivity analysis in structural topology optimization. Computer Methods in Applied Mechanics and Engineering 199, 33âĂŞ36 (2010), 2110 — 2122. Google ScholarCross Ref

23. PolyJet2017. PolyJet Materials Data Sheet. (2017). http://www.stratasys.com/materials.Google Scholar

24. Romain Prévost, Emily Whiting, Sylvain Lefebvre, and Olga Sorkine-Hornung. 2013. Make It Stand: Balancing Shapes for 3D Fabrication. ACM Trans. Graph. 32, 4, Article 81 (July 2013), 10 pages. Google ScholarDigital Library

25. R. Tyrell Rockafellar. 2015. Convex Analysis. Princeton University Press.Google Scholar

26. David W Rosen. 2007. Design for additive manufacturing: a method to explore unexplored regions of the design space. In Eighteenth Annual Solid Freeform Fabrication Symposium. 402–415.Google Scholar

27. Christian Schumacher, Bernd Bickel, Jan Rys, Steve Marschner, Chiara Daraio, and Markus Gross. 2015. Microstructures to Control Elasticity in 3D Printing. ACM Trans. Graph. 34, 4, Article 136 (July 2015), 13 pages. Google ScholarDigital Library

28. Mélina Skouras, Bernhard Thomaszewski, Stelian Coros, Bernd Bickel, and Markus Gross. 2013. Computational Design of Actuated Deformable Characters. ACM Trans. Graph. 32, 4, Article 82 (July 2013), 10 pages. Google ScholarDigital Library

29. Jeffrey Smith, Jessica Hodgins, Irving Oppenheim, and Andrew Witkin. 2002. Creating Models of Truss Structures with Optimization. ACM Trans. Graph. 21, 3 (July 2002), 295–301. Google ScholarDigital Library

30. Ondrej Stava, Juraj Vanek, Bedrich Benes, Nathan Carr, and Radomír Měch. 2012. Stress Relief: Improving Structural Strength of 3D Printable Objects. ACM Trans. Graph. 31, 4, Article 48 (July 2012), 11 pages. Google ScholarDigital Library

31. G. Sved and Z. Ginos. 1968. Structural optimization under multiple loading. International Journal of Mechanical Sciences 10, 10 (1968), 803 — 805. Google ScholarCross Ref

32. Erva Ulu, Emrullah Korkmaz, Kubilay Yay, O. Burak Ozdoganlar, and Levent Burak Kara. 2015. Enhancing the structural performance of additively manufactured objects through build orientation optimization. Journal of Mechanical Design 137, 11 (2015), 111410.Google ScholarCross Ref

33. Nobuyuki Umetani and Ryan Schmidt. 2013. Cross-sectional Structural Analysis for 3D Printing Optimization. In SIGGRAPH Asia 2013 Technical Briefs (SA ’13). ACM, New York, NY, USA, Article 5, 4 pages. Google ScholarDigital Library

34. Weiming Wang, Tuanfeng Y. Wang, Zhouwang Yang, Ligang Liu, Xin Tong, Weihua Tong, Jiansong Deng, Falai Chen, and Xiuping Liu. 2013. Cost-effective Printing of 3D Objects with Skin-frame Structures. ACM Trans. Graph. 32, 6, Article 177 (Nov. 2013), 10 pages. Google ScholarDigital Library

35. Hongyi Xu, Yijing Li, Yong Chen, and Jernej Barbič. 2015. Interactive Material Design using Model Reduction. ACM Trans. on Graphics 34, 2 (2015). Google ScholarDigital Library

36. Hao Zhang, Oliver Van Kaick, and Ramsay Dyer. 2010. Spectral Mesh Processing. Computer Graphics Forum 29, 6 (2010), 1865–1894. Google ScholarCross Ref

37. Xiaolong Zhang, Yang Xia, Jiaye Wang, Zhouwang Yang, Changhe Tu, and Wenping Wang. 2015. Medial Axis Tree-an Internal Supporting Structure for 3D Printing. Comput. Aided Geom. Des. 35, C (May 2015), 149–162. Google ScholarDigital Library

38. Kun Zhou, Jin Huang, John Snyder, Xinguo Liu, Hujun Bao, Baining Guo, and Heung-Yeung Shum. 2005. Large Mesh Deformation Using the Volumetric Graph Laplacian. ACM Trans. Graph. 24, 3 (July 2005), 496–503. Google ScholarDigital Library

39. Qingnan Zhou, Julian Panetta, and Denis Zorin. 2013. Worst-case Structural Analysis. ACM Trans. Graph. 32, 4, Article 137 (July 2013), 12 pages. Google ScholarDigital Library