“Elastic textures for additive fabrication” by Panetta, Zhou, Malomo, Pietroni, Cignoni, et al. …

Conference:

Type(s):

Title:

- Elastic textures for additive fabrication

Presenter(s)/Author(s):

Abstract:

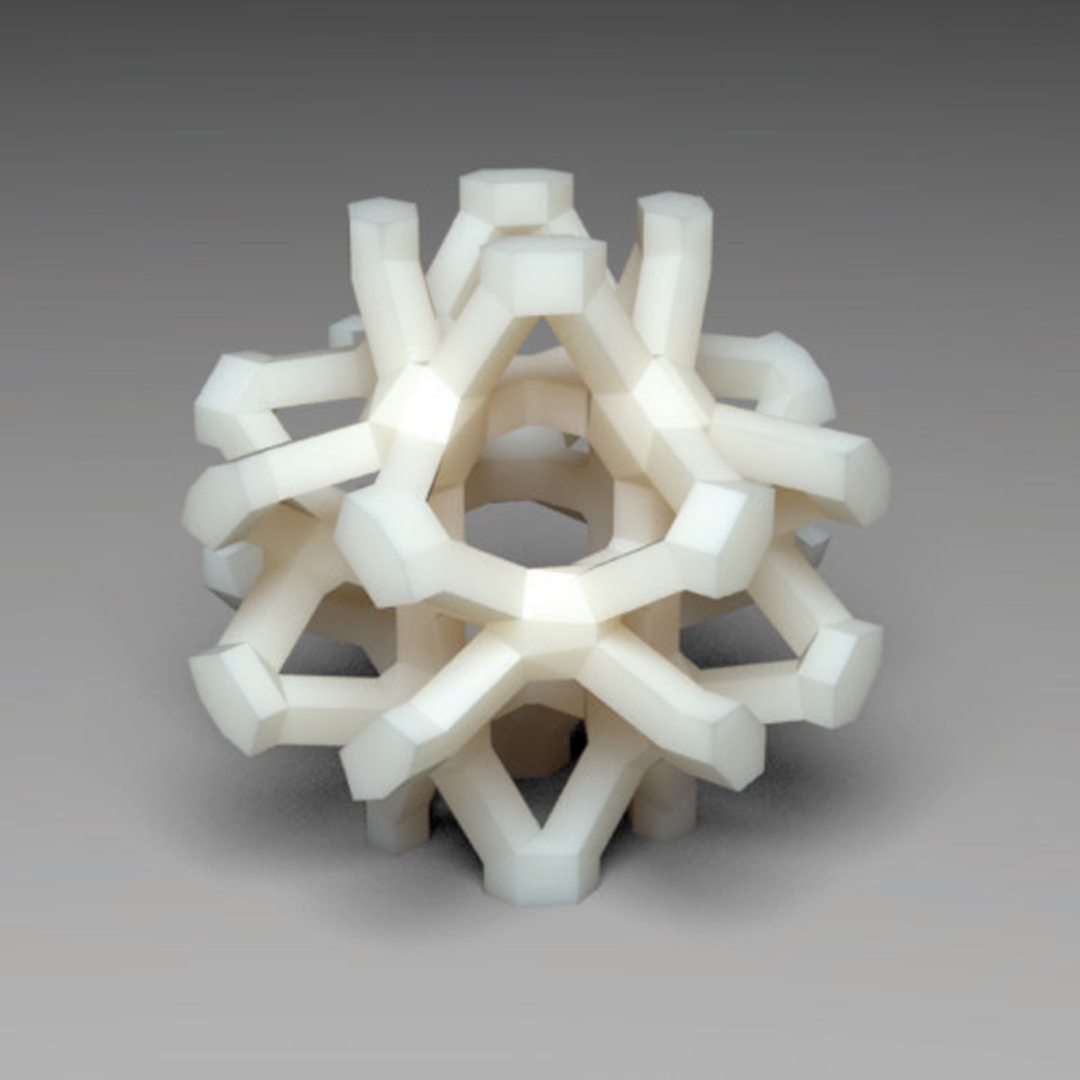

We introduce elastic textures: a set of parametric, tileable, printable, cubic patterns achieving a broad range of isotropic elastic material properties: the softest pattern is over a thousand times softer than the stiffest, and the Poisson’s ratios range from below zero to nearly 0.5. Using a combinatorial search over topologies followed by shape optimization, we explore a wide space of truss-like, symmetric 3D patterns to obtain a small family. This pattern family can be printed without internal support structure on a single-material 3D printer and can be used to fabricate objects with prescribed mechanical behavior. The family can be extended easily to create anisotropic patterns with target orthotropic properties. We demonstrate that our elastic textures are able to achieve a user-supplied varying material property distribution. We also present a material optimization algorithm to choose material properties at each point within an object to best fit a target deformation under a prescribed scenario. We show that, by fabricating these spatially varying materials with elastic textures, the desired behavior is achieved.

References:

1. Agarwal, S., Mierle, K., and Others. Ceres solver. http://ceres-solver.org.Google Scholar

2. Allaire, G. 2002. Shape optimization by the homogenization method, vol. 146. Springer.Google Scholar

3. Andreassen, E., Lazarov, B. S., and Sigmund, O. 2014. Design of manufacturable 3D extremal elastic microstructure. Mechanics of Materials 69, 1, 1–10.Google ScholarCross Ref

4. Avellaneda, M. 1987. Optimal bounds and microgeometries for elastic two-phase composites. SIAM Journal on Applied Mathematics 47, 6, 1216–1228. Google ScholarDigital Library

5. Bendsøe, M. P., and Sigmund, O. 2003. Topology optimization: theory, methods and applications. Springer.Google Scholar

6. Bendsøe, M. P. 1989. Optimal shape design as a material distribution problem. Structural optimization 1, 4, 193–202.Google Scholar

7. Bickel, B., Bächer, M., Otaduy, M. A., Lee, H. R., Pfister, H., Gross, M., and Matusik, W. 2010. Design and fabrication of materials with desired deformation behavior. ACM Trans. Graph. 29, 4 (July), 63:1–63:10. Google ScholarDigital Library

8. Bückmann, T., Stenger, N., Kadic, M., Kaschke, J., Frölich, A., Kennerknecht, T., Eberl, C., Thiel, M., and Wegener, M. 2012. Tailored 3d mechanical metamaterials made by dip-in direct-laser-writing optical lithography. Advanced Materials 24, 20, 2710–2714.Google ScholarCross Ref

9. Cadman, J. E., Zhou, S., Chen, Y., and Li, Q. 2013. On design of multi-functional microstructural materials. Journal of Materials Science 48, 1, 51–66.Google ScholarCross Ref

10. Chen, D., Levin, D. I., Didyk, P., Sitthi-Amorn, P., and Matusik, W. 2013. Spec2fab: a reducer-tuner model for translating specifications to 3d prints. ACM Transactions on Graphics (TOG) 32, 4, 135. Google ScholarDigital Library

11. Cherkaev, A. 2000. Variational methods for structural optimization, vol. 140. Springer.Google ScholarCross Ref

12. Chu, J., Engelbrecht, S., Graf, G., and Rosen, D. W. 2010. A comparison of synthesis methods for cellular structures with application to additive manufacturing. Rapid Prototyping Journal 16, 4, 275–283.Google ScholarCross Ref

13. Cignoni, P., Pietroni, N., Malomo, L., and Scopigno, R. 2014. Field-aligned mesh joinery. ACM Trans. Graph. 33, 1 (Feb.), 11:1–11:12. Google ScholarDigital Library

14. Cioranescu, D., and Donato, P. 1999. An introduction to homogenization. Oxford University Press.Google Scholar

15. Grabovsky, Y., and Kohn, R. V. 1995. Microstructures minimizing the energy of a two phase elastic composite in two space dimensions. II: the Vigdergauz microstructure. Journal of the Mechanics and Physics of Solids 43, 6, 949–972.Google ScholarCross Ref

16. Greaves, G. N., Greer, A. L., Lakes, R. S., and Rouxel, T. 2011. Poisson’s ratio and modern materials. Nature Materials 10, 11, 823–837.Google ScholarCross Ref

17. Guest, J. K., and Prévost, J. H. 2006. Optimizing multifunctional materials: Design of microstructures for maximized stiffness and fluid permeability. International Journal of Solids and Structures 43, 2223, 7028–7047.Google ScholarCross Ref

18. Hart, G. W. 2008. Sculptural forms from hyperbolic tessellations. In Shape Modeling and Applications, 2008. SMI 2008. IEEE International Conference on, IEEE, 155–161.Google ScholarCross Ref

19. Hildebrand, K., Bickel, B., and Alexa, M. 2012. Crdbrd: Shape fabrication by sliding planar slices. Comp. Graph. Forum 31, 2pt3 (May), 583–592. Google ScholarDigital Library

20. Hiller, J., and Lipson, H. 2009. Design and analysis of digital materials for physical 3d voxel printing. Rapid Prototyping Journal 15, 2, 137–149.Google ScholarCross Ref

21. Hollister, S. J. 2005. Porous scaffold design for tissue engineering. Nature Materials 4, 7, 518–524.Google ScholarCross Ref

22. Kang, H. S. 2010. Hierarchical design and simulation of tissue engineering scaffold mechanical, mass transport, and degradation properties. PhD thesis, The University of Michigan.Google Scholar

23. Kharevych, L., Mullen, P., Owhadi, H., and Desbrun, M. 2009. Numerical coarsening of inhomogeneous elastic materials. ACM Trans. Graph. 28, 3 (July), 51:1–51:8. Google ScholarDigital Library

24. Lin, C. Y., Kikuchi, N., and Hollister, S. J. 2004. A novel method for biomaterial scaffold internal architecture design to match bone elastic properties with desired porosity. Journal of Biomechanics 37, 5, 623–636.Google ScholarCross Ref

25. Lin, C.-Y., Hsiao, C.-C., Chen, P.-Q., and Hollister, S. J. 2004. Interbody fusion cage design using integrated global layout and local microstructure topology optimization. Spine 29, 16, 1747–1754. PMID: 15303018.Google ScholarCross Ref

26. Liu, L., James, R. D., and Leo, P. H. 2007. Periodic inclusionatrix microstructures with constant field inclusions. Metallurgical and Materials Transactions A 38, 4, 781–787.Google ScholarCross Ref

27. Mela, K., and Koski, J. 2013. Distributed loads in truss topology optimization. In Proceedings of the 10th world congress on structural and multidisciplinary optimization, Orlando.Google Scholar

28. Milton, G. W. 2002. The theory of composites. Cambridge University Press.Google Scholar

29. Mironov, V., Visconti, R. P., Kasyanov, V., Forgacs, G., Drake, C. J., and Markwald, R. R. 2009. Organ printing: tissue spheroids as building blocks. Biomaterials 30, 12, 2164–2174.Google ScholarCross Ref

30. Mitani, J., and Suzuki, H. 2004. Making papercraft toys from meshes using strip-based approximate unfolding. In ACM SIGGRAPH 2004 Papers, ACM, New York, NY, USA, SIGGRAPH ’04, ACM, 259–263. Google ScholarDigital Library

31. Mori, Y., and Igarashi, T. 2007. Plushie: An interactive design system for plush toys. In ACM SIGGRAPH 2007 Papers, ACM, New York, NY, USA, SIGGRAPH ’07, ACM. Google ScholarDigital Library

32. Nakasone, P., and Silva, E. 2010. Dynamic design of piezoelectric laminated sensors and actuators using topology optimization. Journal of Intelligent Material Systems and Structures 21, 16, 1627–1652.Google ScholarCross Ref

33. Radman, A., Huang, X., and Xie, Y. 2013. Topological optimization for the design of microstructures of isotropic cellular materials. Engineering Optimization 45, 11, 1331–1348.Google ScholarCross Ref

34. Schwartzburg, Y., and Pauly, M. 2013. Fabrication-aware design with intersecting planar pieces. Comput. Graph. Forum 32, 2, 317–326.Google ScholarCross Ref

35. Schwartzburg, Y., Testuz, R., Tagliasacchi, A., and Pauly, M. 2014. High-contrast computational caustic design. ACM Trans. Graph. 33, 4 (July), 74:1–74:11. Google ScholarDigital Library

36. Schwerdtfeger, J., Wein, F., Leugering, G., Singer, R. F., Krner, C., Stingl, M., and Schury, F. 2011. Design of auxetic structures via mathematical optimization. Advanced Materials 23, 22, 2650–2654.Google ScholarCross Ref

37. Si, H. 2010. A quality tetrahedral mesh generator and a 3D Delaunay triangulator. URL http://tetgen.berlios.de.Google Scholar

38. Sigmund, O. 1995. Tailoring materials with prescribed elastic properties. Mechanics of Materials 20, 4, 351–368.Google ScholarCross Ref

39. Skouras, M., Thomaszewski, B., Coros, S., Bickel, B., and Gross, M. 2013. Computational design of actuated deformable characters. ACM Transactions on Graphics (TOG) 32, 4, 82. Google ScholarDigital Library

40. Torquato, S., and Donev, A. 2004. Minimal surfaces and multifunctionality. Proceedings of the Royal Society of London. Series A: Mathematical, Physical and Engineering Sciences 460, 2047, 1849–1856.Google Scholar

41. Torquato, S., Hyun, S., and Donev, A. 2002. Multifunctional composites: optimizing microstructures for simultaneous transport of heat and electricity. Physical review letters 89, 26, 266601.Google Scholar

42. Torquato, S., Hyun, S., and Donev, A. 2003. Optimal design of manufacturable three-dimensional composites with multifunctional characteristics. Journal of Applied Physics 94, 9, 5748–5755.Google ScholarCross Ref

43. Torquato, S. 2002. Random heterogeneous materials: microstructure and macroscopic properties, vol. 16. Springer.Google Scholar

44. Vidimče, K., Wang, S.-P., Ragan-Kelley, J., and Matusik, W. 2013. Openfab: A programmable pipeline for multimaterial fabrication. ACM Transactions on Graphics (TOG) 32, 4, 136. Google ScholarDigital Library

45. Weyrich, T., Peers, P., Matusik, W., and Rusinkiewicz, S. 2009. Fabricating microgeometry for custom surface reflectance. ACM Trans. on Graphics (Proc. SIGGRAPH) 28, 3, 32:1–32:6. Google ScholarDigital Library