“Origami Optics” by Tremblay, Ford, Stack and Morrison

Conference:

- SIGGRAPH 2008

-

More from SIGGRAPH 2008:

Type(s):

Entry Number: 31

Title:

- Origami Optics

Presenter(s):

Description:

With smaller, slimmer and lighter cameras in high demand for consumer portable devices and military applications, optics is challenged with the question- how can we make optics smaller without giving up the functionality associated with larger cameras? A big part of the problem is simply scalability. As conventional imaging systems are scaled down, the focal length (i.e. magnification) scales down with the allowed optical thickness. Being additionally limited by the size of the smallest available image sensors, we find that these cameras are usually limited to short focal length, small aperture lenses- what you find in the majority of cell phones. While fine for many applications, there are others, such as surveillance and high-end portable device cameras that could benefit dramatically from larger magnification and better light collection with minimal added bulk or thickness.

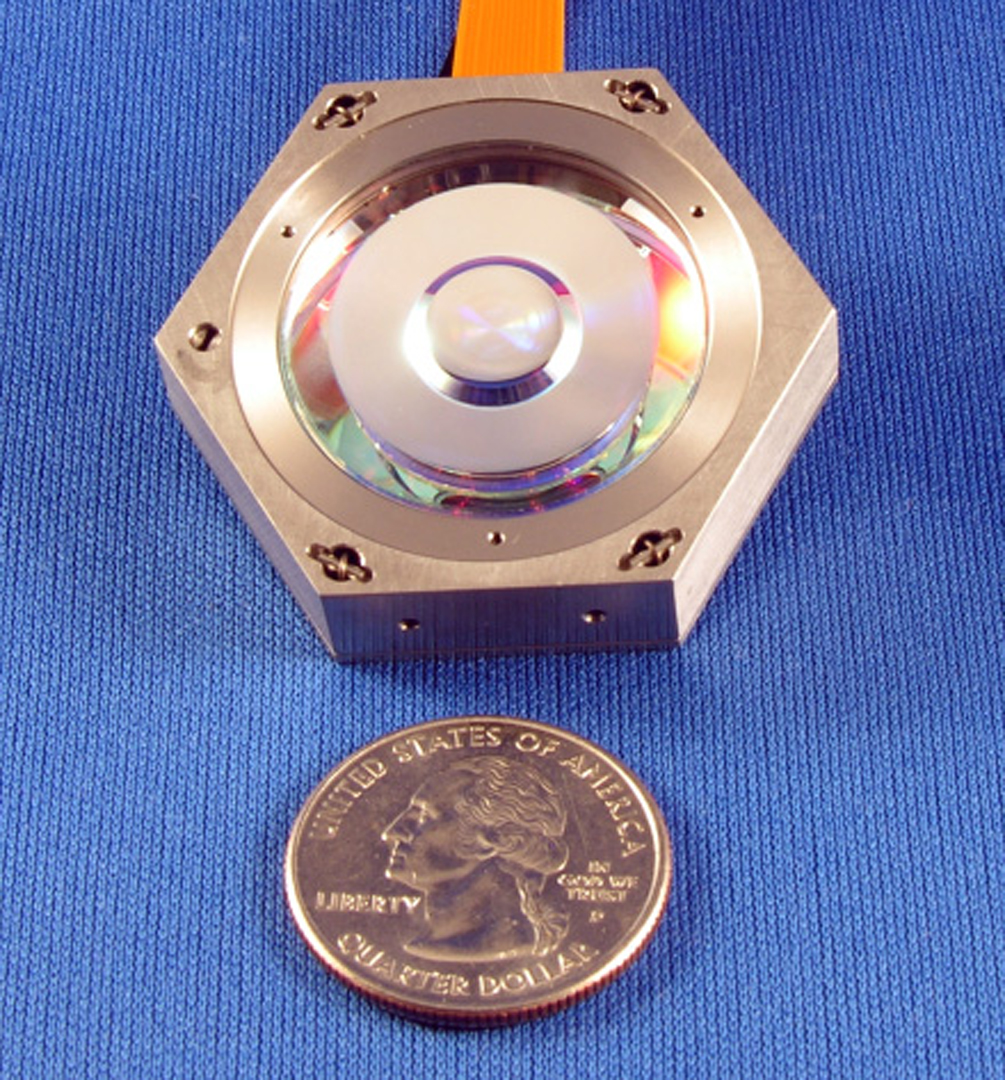

With up to eight reflections, large ray angles, a thin aspect ratio and a large field of view (for a reflective design); “origami optic” designs can be seen as a somewhat extreme extension of traditional reflective telescope design. Light enters the optic through an annular aperture and is reflected or “folded” multiple times within the optical thickness. Compared to a refractive lens, where light propagates in one direction as it is focused to the image plane, the multiple-reflection geometry reflects or “folds” the optical path multiple times back onto itself and allows for greatly reduced overall thickness for a given focal length.

The enabling technology for this type of optical design is single-point diamond turning (SPDT). The recent maturity of SPDT for visible light optics in addition to its ability to maintain tight tolerances and fabricate complex surface shapes makes it a nearly ideal fabrication method for our designs.

Acknowledgements:

This research was supported by DARPA via the MONTAGE program, grant no HR0011-04-I-0045; and by the Natural Sciences and Engineering Research Council of Canada (NSERC) through a graduate student scholarship.