“ActMold: Rapid Prototyping of Electronic Circuits on 2.5D Objects With Interactive Vacuum Forming” by Yamaoka, Kakehi and Kawahara

Notice: Pod Template PHP code has been deprecated, please use WP Templates instead of embedding PHP. has been deprecated since Pods version 2.3 with no alternative available. in /data/siggraph/websites/history/wp-content/plugins/pods/includes/general.php on line 518

Conference:

- SIGGRAPH 2017

-

More from SIGGRAPH 2017:

Notice: Array to string conversion in /data/siggraph/websites/history/wp-content/plugins/siggraph-archive-plugin/src/next_previous/source.php on line 345

Notice: Array to string conversion in /data/siggraph/websites/history/wp-content/plugins/siggraph-archive-plugin/src/next_previous/source.php on line 345

Type(s):

Title:

- ActMold: Rapid Prototyping of Electronic Circuits on 2.5D Objects With Interactive Vacuum Forming

Presenter(s):

Description:

Recently, fabrication tools such as 3D printers have become widely available. So have prototyping tools that can print solid objects, such as electric circuits. But 3D printers are still slow. Recycling is difficult because the filament material in most printers is for one-time use only. And it is difficult to reprint circuits because they are integrated into the printed objects.

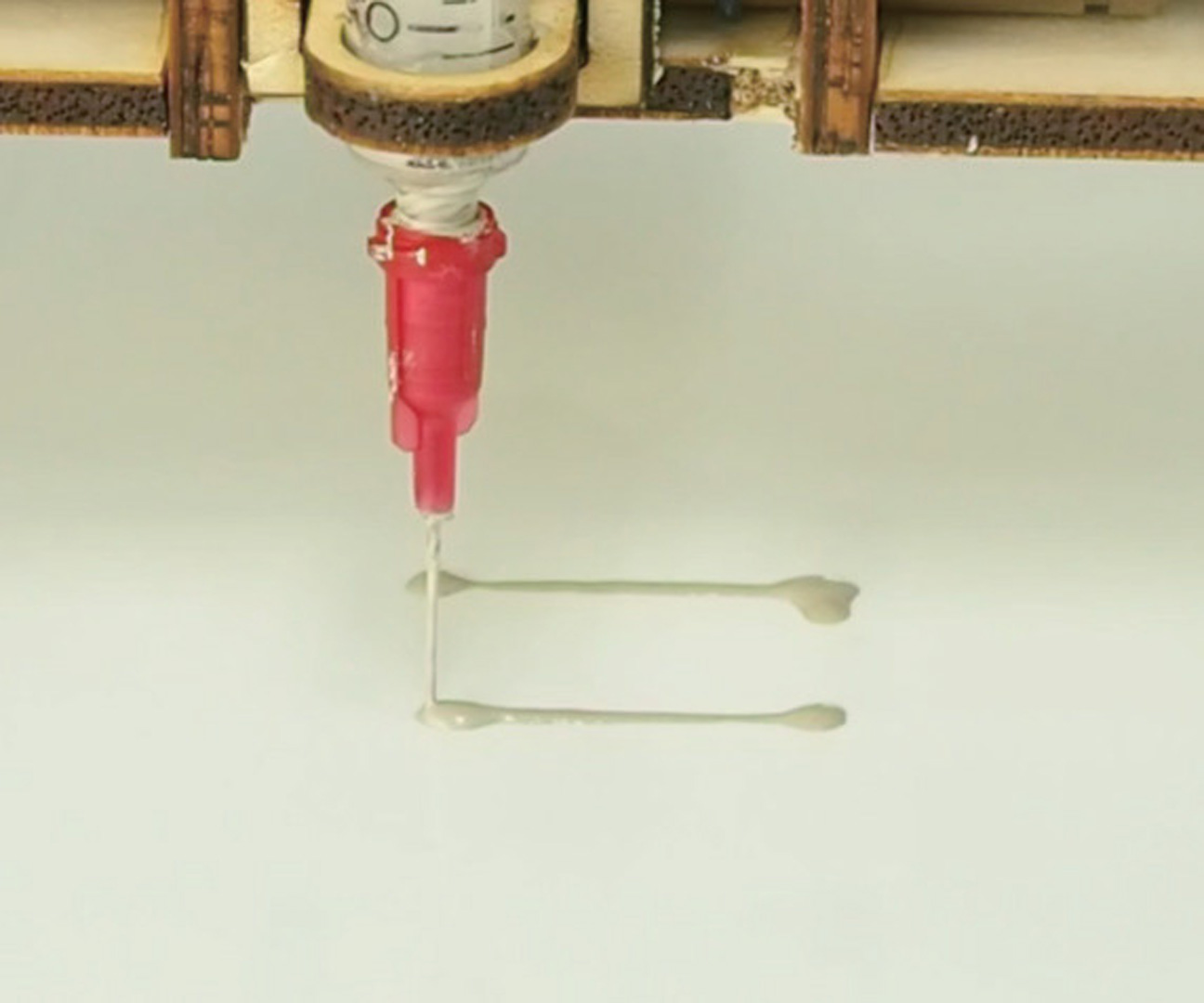

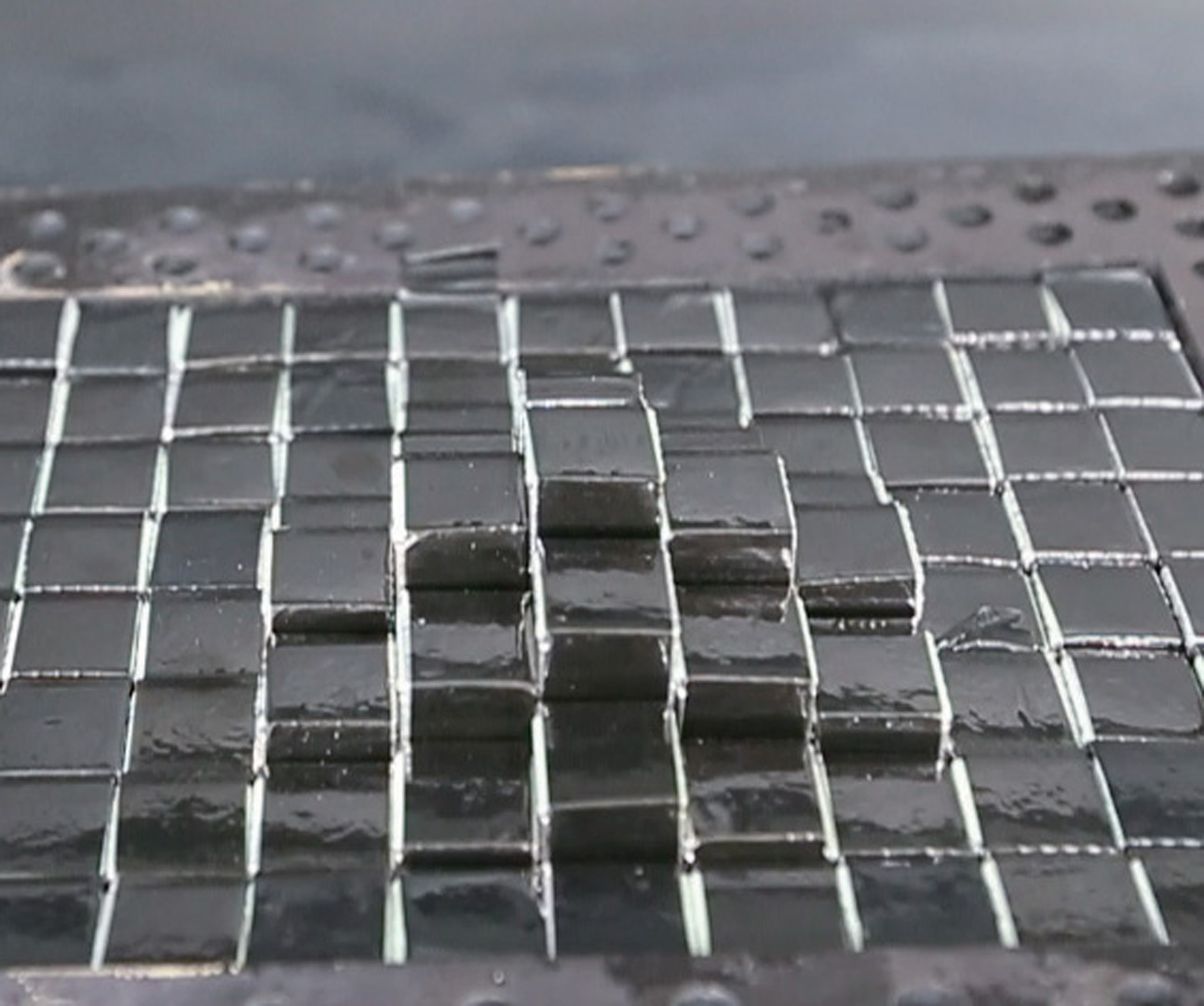

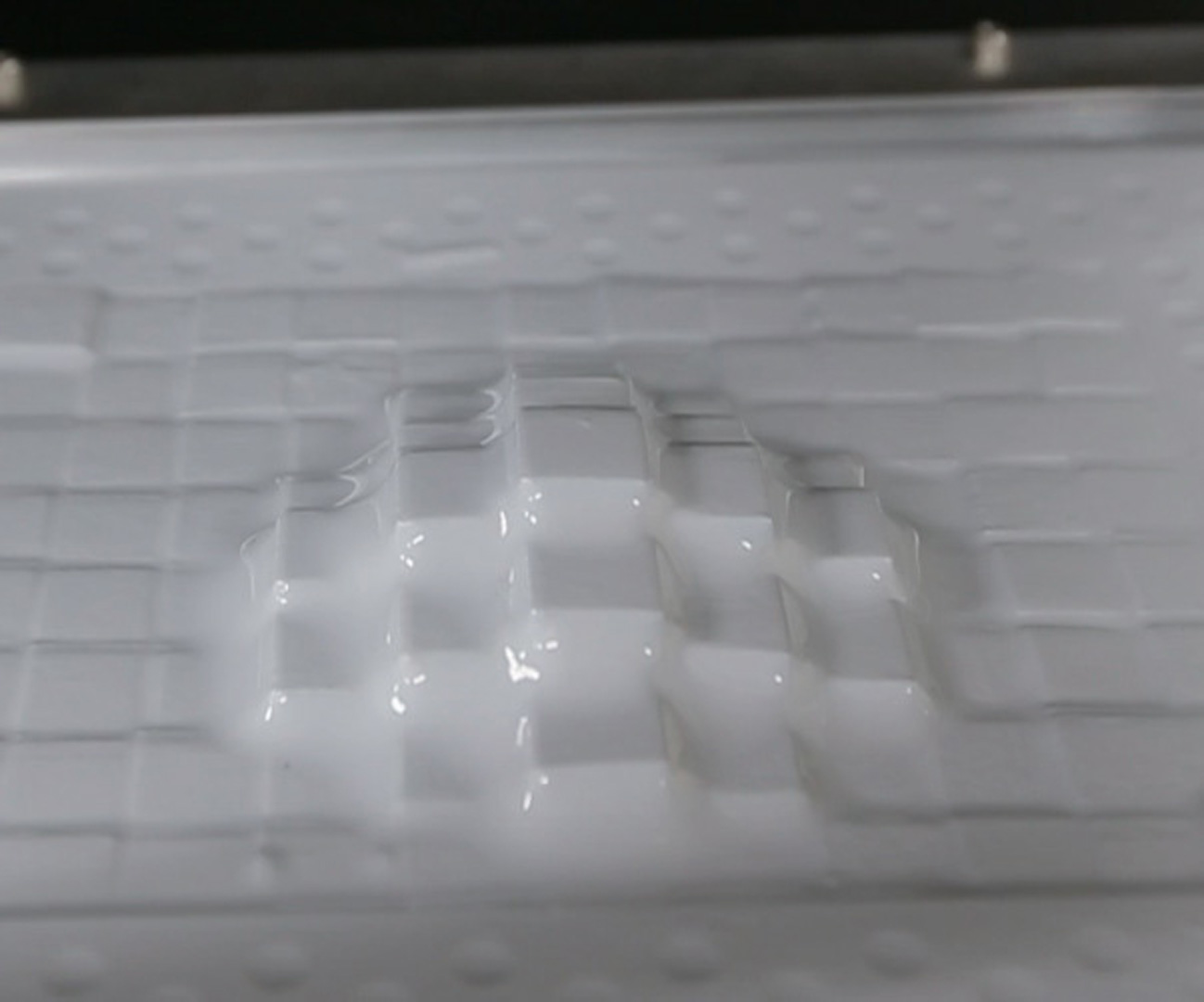

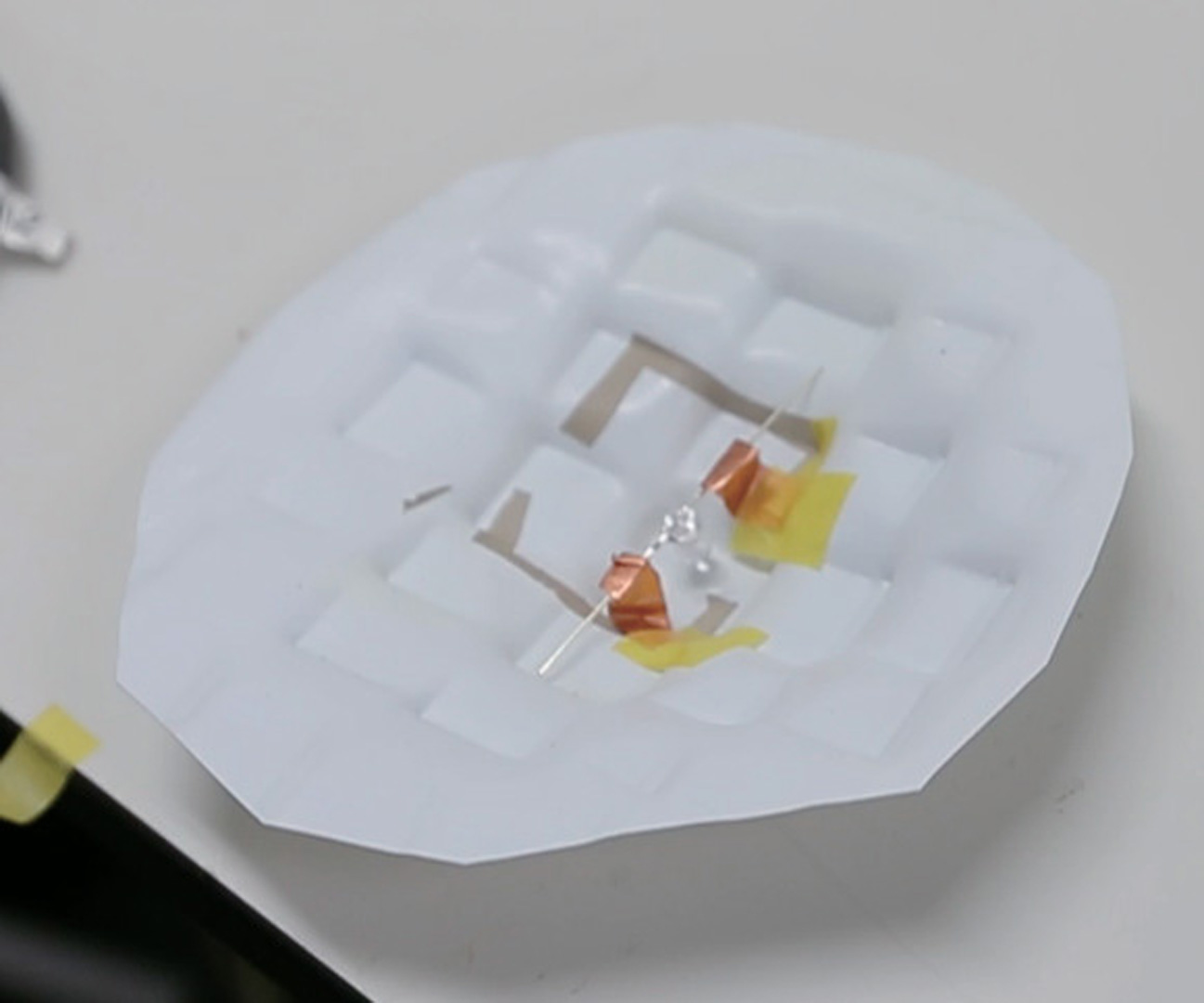

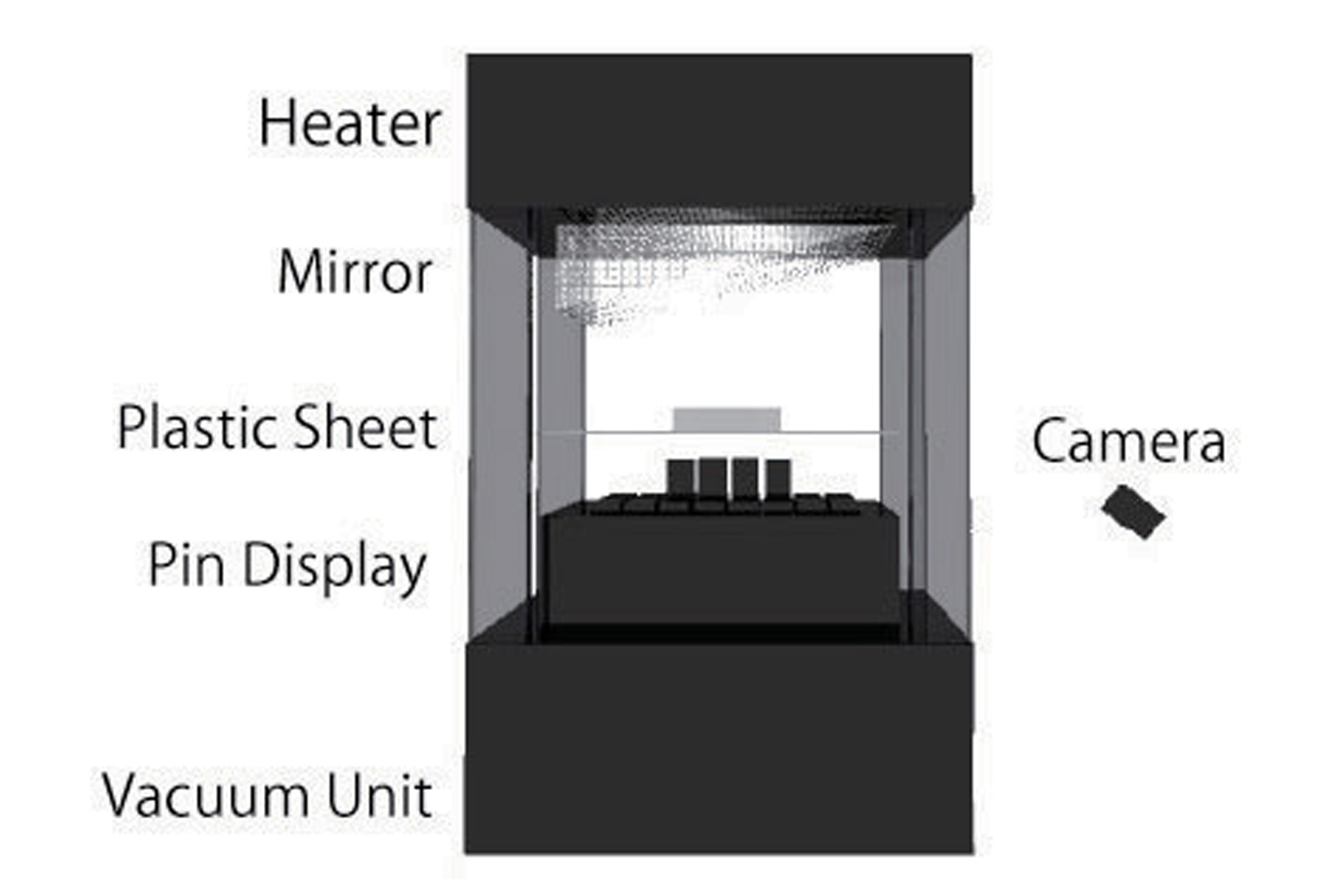

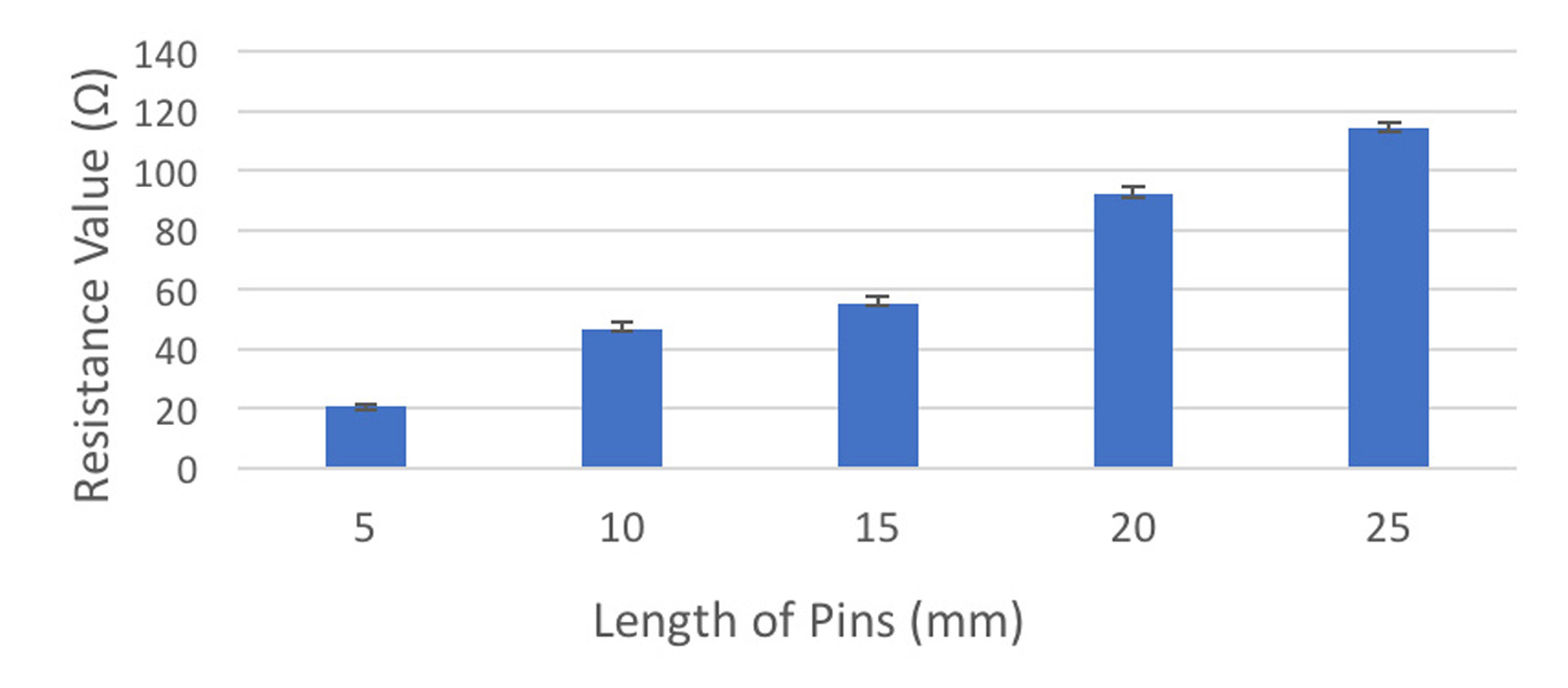

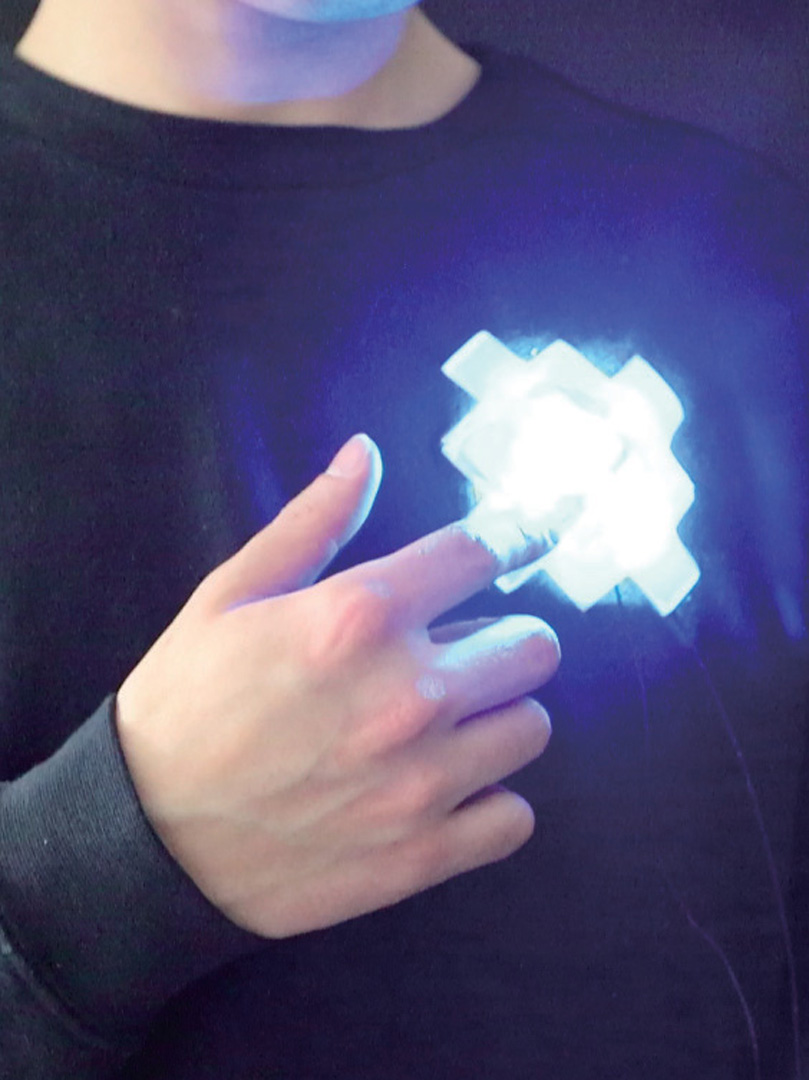

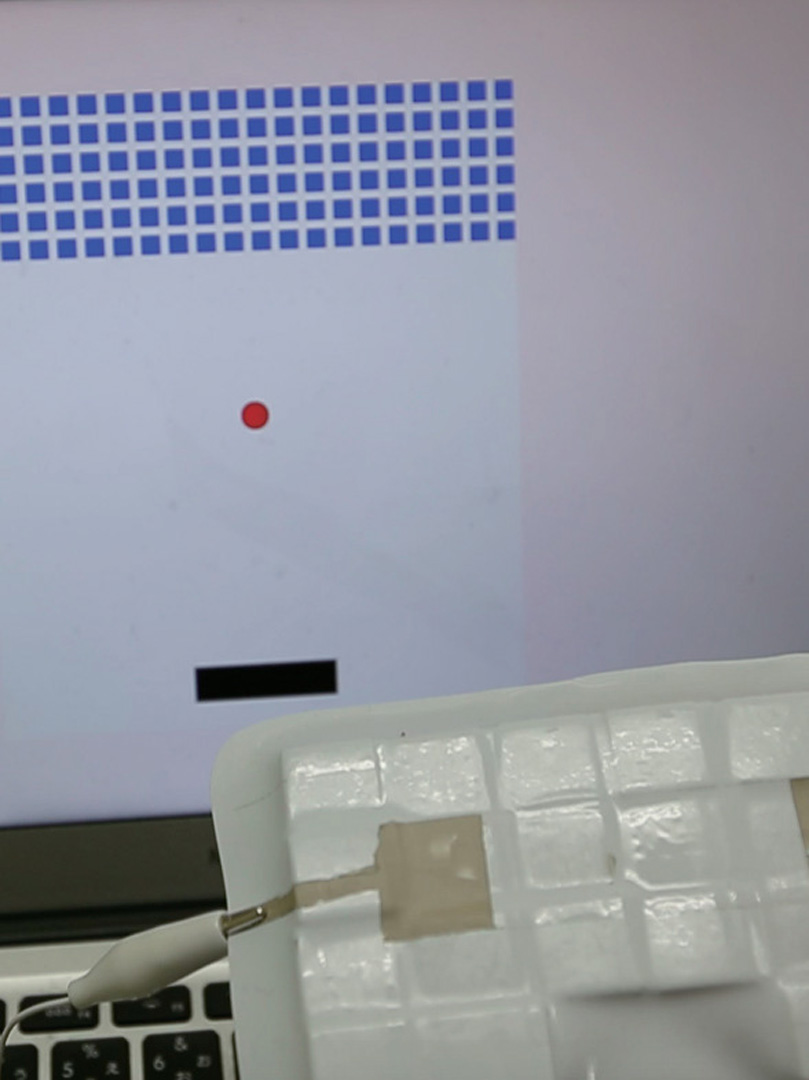

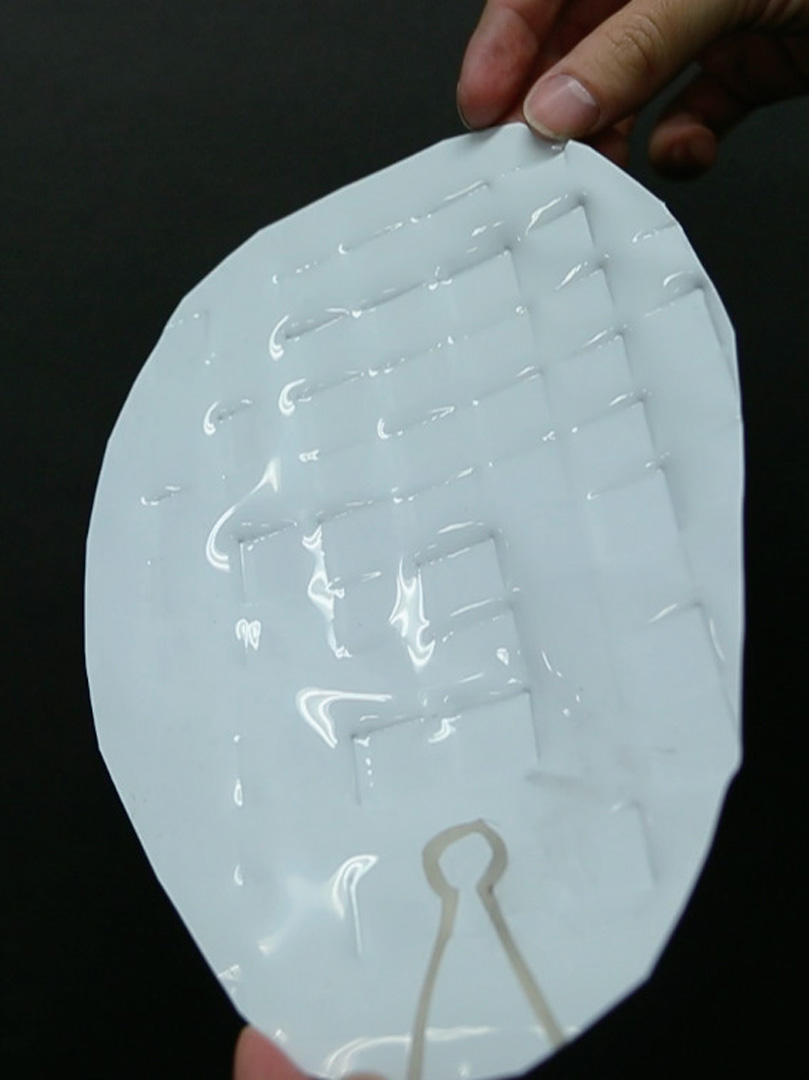

ActMold, which can quickly mold 2.5-dimensional (2.5D) objects, is an evolving solution to these issues. It combines a dynamical shape display and a vacuum-forming system that can reuse molded objects, and it prints patterns of conductive ink on a plastic sheet in advance, so the objects can work as electronic interfaces. Before modifying the plastic sheet, the user can print a circuit on its surface with conductive ink to add computational functions to the molded prototypes. After printing the circuit, the user can create 2.5D objects using vacuum forming. When heat is applied to the molded object, it can be reversed to a flat surface. The system allows users to change design repeatedly. After the plastic material is soft again, the user can remove the components and erase the printed circuit by rubbing the surface with acetone.

Acknowledgements:

This research is supported by ERATO, JST.