“Wire mesh design” by Garg, Sageman-Furnas, Deng, Yue, Grinspun, et al. …

Conference:

Type(s):

Title:

- Wire mesh design

Session/Category Title: Fabrication-Oriented Design

Presenter(s)/Author(s):

Moderator(s):

Abstract:

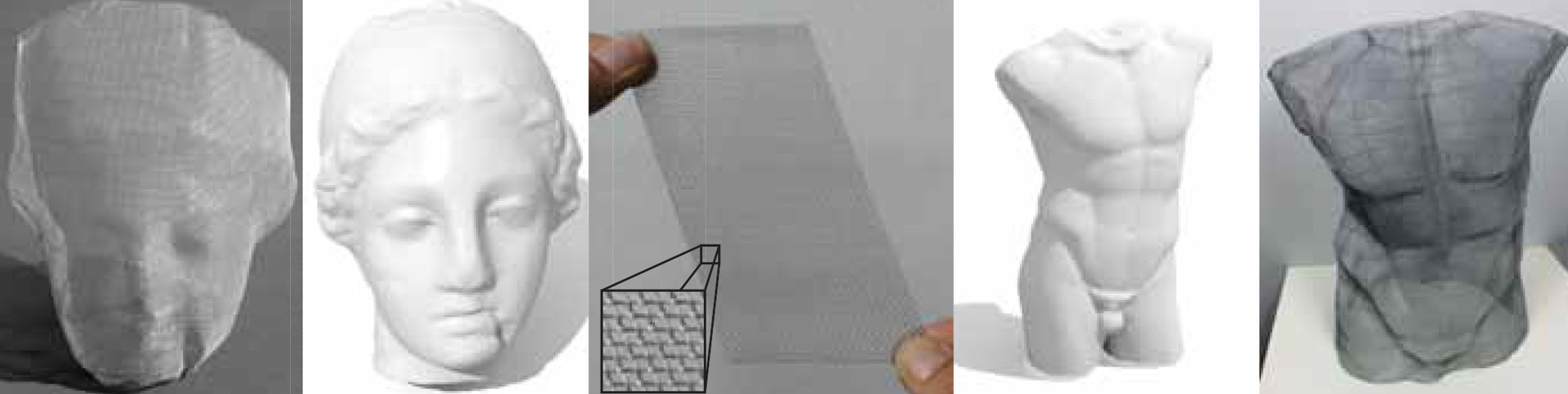

We present a computational approach for designing wire meshes, i.e., freeform surfaces composed of woven wires arranged in a regular grid. To facilitate shape exploration, we map material properties of wire meshes to the geometric model of Chebyshev nets. This abstraction is exploited to build an efficient optimization scheme. While the theory of Chebyshev nets suggests a highly constrained design space, we show that allowing controlled deviations from the underlying surface provides a rich shape space for design exploration. Our algorithm balances globally coupled material constraints with aesthetic and geometric design objectives that can be specified by the user in an interactive design session. In addition to sculptural art, wire meshes represent an innovative medium for industrial applications including composite materials and architectural façades. We demonstrate the effectiveness of our approach using a variety of digital and physical prototypes with a level of shape complexity unobtainable using previous methods.

References:

1. Adkins, J. E. 1956. Finite Plane Deformation of Thin Elastic Sheets Reinforced with Inextensible Cords. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences 249, 961, 125–150.Google ScholarCross Ref

2. Aono, M., Denti, P., Breen, D. E., and Wozny, M. J. 1996. Fitting a woven cloth model to a curved surface: dart insertion. IEEE Computer Graphics and Applications 16, 5, 60–70. Google ScholarDigital Library

3. Aono, M., Breen, D. E., and Wozny, M. J. 2001. Modeling methods for the design of 3D broadcloth composite parts. Computer-Aided Design 33, 13, 989–1007.Google ScholarCross Ref

4. Aono, M. 1994. Computer-Aided Geometric Design for Forming Woven Cloth Composites. PhD thesis, Rensselaer Polytechnic Institute. Google ScholarDigital Library

5. Baillargeon, Y., and Vu-Khanh, T. 2001. Prediction of fiber orientation and microstructure of woven fabric composites after forming. Composite Structures 52, 3-4, 475–481. Google ScholarDigital Library

6. Bakelman, I. Y. 1965. Chebyshev networks in manifolds of bounded curvature. Trudy Matematicheskogo Instituta im. VA Steklova 76, 124–129. Google ScholarDigital Library

7. Bieberbach, L. 1926. über Tchebychefsche Netze auf Flächen negativer krümmung, sowie auf einigen weiteren flächenarten. Preuss. Akad. Wiss., Phys. Math. Kl 23, 294–321.Google Scholar

8. Bo, P., Pottmann, H., Kilian, M., Wang, W., and Wallner, J. 2011. Circular arc structures. ACM Trans. Graph. (SIGGRAPH ’11) 30, 4, 101:1–101:11. Google ScholarDigital Library

9. Bobenko, A. I., and Pinkall, U. 1996. Discrete surfaces with constant negative Gaussian curvature and the Hirota equation. Journal of Differential Geometry 43, 3, 527–611. Google ScholarDigital Library

10. Bouaziz, S., Deuss, M., Schwartzburg, Y., Weise, T., and Pauly, M. 2012. Shape-up: Shaping discrete geometry with projections. Comp. Graph. Forum (SGP ’12) 31, 5, 1657–1667. Google ScholarDigital Library

11. Burago, Y. D., Ivanov, S. V., and Malev, S. G. 2007. Remarks on Chebyshev Coordinates. Journal of Mathematical Sciences 140, 4, 497–501. Google ScholarDigital Library

12. Cignoni, P., Pietroni, N., Malomo, L., and Scopigno, R. 2014. Field-aligned mesh joinery. ACM Trans. Graph. 33, 1, 11:1–11:12. Google ScholarDigital Library

13. de Goes, F., Alliez, P., Owhadi, H., and Desbrun, M. 2013. On the equilibrium of simplicial masonry structures. ACM Trans. Graph. (SIGGRAPH ’13) 32, 4, 93:1–93:10. Google ScholarDigital Library

14. Deng, B., Bouaziz, S., Deuss, M., Zhang, J., Schwartzburg, Y., and Pauly, M. 2013. Exploring local modifications for constrained meshes. Computer Graphics Forum (EUROGRAPHICS ’13) 32, 2, 11–20. Google ScholarDigital Library

15. Deng, B., Bouaziz, S., Deuss, M., Kaspar, A., Schwartzburg, Y., and Pauly, M. 2014. Interactive design exploration for constrained meshes. Computer-Aided Design. To appear. Google ScholarDigital Library

16. Eigensatz, M., Kilian, M., Schiftner, A., Mitra, N., Pottmann, H., and Pauly, M. 2010. Paneling architectural freeform surfaces. ACM Trans. Graph. (SIGGRAPH ’10) 29, 4, 45:1–45:10. Google ScholarDigital Library

17. Ghys, É. 2011. Sur la coupe des vêtements: variation autour d’un thème de Tchebychev. L’Enseignement Mathématique Revue Internationale 2e Sèrie 57, 1–2, 165–208. Google ScholarDigital Library

18. Hazzidakis, J. N. 1879. Über einige Eigenschaften der Flächen mit constantem Krümmungsmass. Journal für die reine und angewandte Mathematik 88, 68–73.Google Scholar

19. Hoffmann, T. 1999. Discrete Amsler surfaces and a discrete Painlevé III equation. Oxford Lecture Series in Mathematics and its Applications 16, 83–96.Google Scholar

20. Liu, Y., Pottmann, H., Wallner, J., Yang, Y.-L., and Wang, W. 2006. Geometric modeling with conical meshes and developable surfaces. ACM Trans. Graph. (SIGGRAPH ’06) 25, 3, 681–689. Google ScholarDigital Library

21. Liu, Y., Pan, H., Snyder, J., Wang, W., and Guo, B. 2013. Computing self-supporting surfaces by regular triangulation. ACM Trans. Graph. (SIGGRAPH ’13) 32, 4, 92:1–92:10. Google ScholarDigital Library

22. Möbius, J., and Kobbelt, L. 2012. Openflipper: An open source geometry processing and rendering framework. In Curves and Surfaces, J.-D. Boissonnat, P. Chenin, A. Cohen, C. Gout, T. Lyche, M.-L. Mazure, and L. Schumaker, Eds., vol. 6920 of Lecture Notes in Computer Science. Springer Berlin Heidelberg, 488–500. Google ScholarDigital Library

23. Panozzo, D., Block, P., and Sorkine-Hornung, O. 2013. Designing unreinforced masonry models. ACM Trans. Graph. (SIGGRAPH ’13) 32, 4, 91:1–91:12. Google ScholarDigital Library

24. Pinkall, U. 2008. Designing cylinders with constant negative curvature. In Discrete Differential Geometry. Springer, 57–66. Google ScholarDigital Library

25. Pipkin, A. C. 1984. Equilibrium of Tchebychev nets. Archive for Rational Mechanics and Analysis 85, 1, 81–97.Google ScholarCross Ref

26. Pipkin, A. C. 1986. Continuously distributed wrinkles in fabrics. Archive for Rational Mechanics and Analysis 95, 2, 93–115. Google ScholarDigital Library

27. Poranne, R., Ovreiu, E., and Gotsman, C. 2013. Interactive planarization and optimization of 3D meshes. Computer Graphics Forum 32, 1, 152–163. Google ScholarDigital Library

28. Pottmann, H., Schiftner, A., Bo, P., Schmiedhofer, H., Wang, W., Baldassini, N., and Wallner, J. 2008. Freeform surfaces from single curved panels. ACM Trans. Graph. (SIGGRAPH ’08) 27, 3, 76:1–76:10. Google ScholarDigital Library

29. Pottmann, H., Huang, Q., Deng, B., Schiftner, A., Kilian, M., Guibas, L., and Wallner, J. 2010. Geodesic patterns. ACM Trans. Graph. (SIGGRAPH ’10) 29, 4, 43:1–43:10. Google ScholarDigital Library

30. Rivlin, R. S. 1958. The deformation of a membrane formed by inextensible cords. Archive for Rational Mechanics and Analysis 2, 1, 447–476. Google ScholarDigital Library

31. Rivlin, R. S. 1964. Networks of inextensible cords. In Nonlinear Problems of Engineering. Academic Press Professional, Inc., New York, 51–64. Google ScholarDigital Library

32. Rivlin, R. S. 1997. Plane Strain of a Net Formed by Inextensible Cords. In Collected Papers of R. S. Rivlin, G. I. Barenblatt and D. D. Joseph, Eds. Springer New York, 511–534. Google ScholarDigital Library

33. Robertson, R. E., Hsiue, E. S., Sickafus, E. N., and Yeh, G. S. Y. 1981. Fiber rearrangements during the molding of continuous fiber composites. I. Flat cloth to a hemisphere. Polymer composites 2, 3, 126–131.Google Scholar

34. Robertson, R. E., Chu, T. J., Gerard, R. J., Kim, J. H., Park, M., Kim, H. G., and Peterson, R. C. 2000. Three-dimensional fiber reinforcement shapes obtainable from flat, bidirectional fabrics without wrinkling or cutting. Part 2: a single n-sided pyramid, cone, or round box. Composites Part A: Applied Science and Manufacturing 31, 11, 1149–1165.Google ScholarCross Ref

35. Samelson, S. L., and Dayawansa, W. P. 1995. On the Existence of Global Tchebychev Nets. Transactions of the American Mathematical Society 347, 2, 651–660.Google ScholarCross Ref

36. Samelson, S. L. 1991. Global Tchebychev Nets on Complete Two-Dimensional Riemannian Surfaces. Archive for Rational Mechanics and Analysis 114, 3, 237–254.Google ScholarCross Ref

37. Sauer, R. 1970. Differenzengeometrie. Springer Verlag, Berlin.Google Scholar

38. Schwartzburg, Y., and Pauly, M. 2013. Fabrication-aware design with intersecting planar pieces. Computer Graphics Forum (EUROGRAPHICS ’13) 32, 2, 317–326.Google Scholar

39. Tschebyscheff, P. L. 1878. Sur la coupe des vêtements, “On the cutting of garments”. Association francaise pour l’avancement des sciences, 154–155.Google Scholar

40. van West, B. P., Pipes, R. B., and Keefe, M. 1990. A Simulation of the Draping of Bidirectional Fabrics over Arbitrary Surfaces. Journal of the Textile Institute 81, 4, 448–460.Google ScholarCross Ref

41. Voss, A. 1882. Über ein neues Princip der Abbildung krummer Oberflächen. Mathematische Annalen 19, 1–26.Google ScholarCross Ref

42. Vouga, E., Höbinger, M., Wallner, J., and Pottmann, H. 2012. Design of self-supporting surfaces. ACM Trans. Graph. (SIGGRAPH ’12) 31, 4, 87:1–87:11. Google ScholarDigital Library

43. Wang, W. B., and Pipkin, A. C. 1986. Inextensible networks with bending stiffness. Quarterly Journal of Mechanics & Applied Mathematics 39, 3, 343–359.Google ScholarCross Ref

44. Wang, J., Paton, R., and Page, J. R. 1999. The draping of woven fabric preforms and prepregs for production of polymer composite components. Composites Part A: Applied Science and Manufacturing 30, 6, 757–765.Google ScholarCross Ref

45. Wang, W., Liu, Y., Yan, D., Chan, B., Ling, R., and Sun, F. 2008. Hexagonal meshes with planar faces. HKU CS Tech Report TR-2008-13.Google Scholar

46. Wunderlich, W. 1951. Zur Differenzengeometrie der Flächen konstanter negativer Krümmung. Springer Verlag.Google Scholar

47. Ye, L., and Daghyani, H. R. 1997. Characteristics of woven fibre fabric reinforced composites in forming process. Composites Part A: Applied Science and Manufacturing 28, 9, 869–874.Google ScholarCross Ref