“MultiFab: a machine vision assisted platform for multi-material 3D printing” by Sitthi-amorn, Ramos, Wangy, Kwan, Lan, et al. …

Conference:

Type(s):

Title:

- MultiFab: a machine vision assisted platform for multi-material 3D printing

Presenter(s)/Author(s):

Abstract:

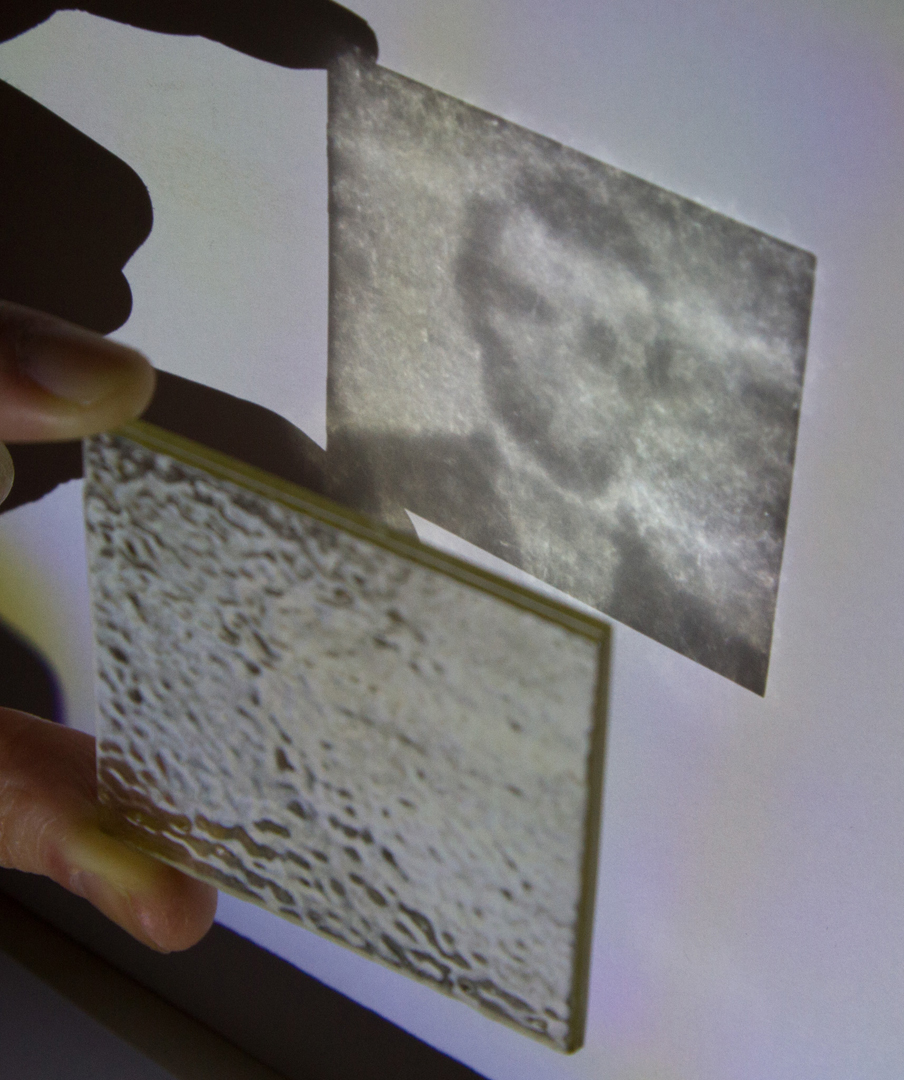

We have developed a multi-material 3D printing platform that is high-resolution, low-cost, and extensible. The key part of our platform is an integrated machine vision system. This system allows for self-calibration of printheads, 3D scanning, and a closed-feedback loop to enable print corrections. The integration of machine vision with 3D printing simplifies the overall platform design and enables new applications such as 3D printing over auxiliary parts. Furthermore, our platform dramatically expands the range of parts that can be 3D printed by simultaneously supporting up to 10 different materials that can interact optically and mechanically. The platform achieves a resolution of at least 40 μm by utilizing piezoelectric inkjet printheads adapted for 3D printing. The hardware is low cost (less than $7,000) since it is built exclusively from off-the-shelf components. The architecture is extensible and modular — adding, removing, and exchanging printing modules can be done quickly. We provide a detailed analysis of the system’s performance. We also demonstrate a variety of fabricated multi-material objects.

References:

1. 3D Systems. Projet 5500X http://www.3dsystems.com/3d-printers/professional/projet-5500x.Google Scholar

2. Bickel, B., Bächer, M., Otaduy, M. A., Lee, H. R., Pfister, H., Gross, M., and Matusik, W. 2010. Design and fabrication of materials with desired deformation behavior. ACM Trans. Graph. 29, 4 (July), 63:1–63:10. Google ScholarDigital Library

3. Boykov, Y., and Kolmogorov, V. 2004. An experimental comparison of min-cut/max-flow algorithms for energy minimization in vision. IEEE Trans. Pattern Anal. Mach. Intell. 26, 9 (Sept.), 1124–1137. Google ScholarDigital Library

4. Burg, T., Cass, C. A. P., Groff, R., Pepper, M., and Burg, K. J. L. 2010. Building off-the-shelf tissue-engineered composites. Phil. Trans. R. Soc. A 368, 1839âĂŞ–1862.Google ScholarCross Ref

5. Campbell, T. A., and Ivanova, O. S. 2013. 3D printing of multifunctional nanocomposites. Nano Today 8, 2, 119–120.Google ScholarCross Ref

6. Chen, D., Levin, D. I. W., Didyk, P., Sitthi-Amorn, P., and Matusik, W. 2013. Spec2Fab: A reducer-tuner model for translating specifications to 3D prints. ACM Trans. Graph. 32, 4, 135:1–135:10. Google ScholarDigital Library

7. Cho, W., Sachs, E. M., Patrikalakis, N. M., and Troxel, D. E. 2003. A dithering algorithm for local composition control with three-dimensional printing. Computer-aided design 35, 9, 851–867.Google Scholar

8. Choi, J.-W., Kim, H.-C., and Wicker, R. 2011. Multi-material stereolithography. Journal of Materials Processing Technology 211, 3, 318–328.Google ScholarCross Ref

9. Dimas, L. S., Bratzel, G. H., Eylon, I., and Buehler, M. J. 2013. Tough composites inspired by mineralized natural materials: Computation, 3D printing, and testing. Advanced Functional Materials 23, 36, 4629–4638.Google ScholarCross Ref

10. Dong, Y., Wang, J., Pellacini, F., Tong, X., and Guo, B. 2010. Fabricating spatially-varying subsurface scattering. ACM Trans. Graph. 29, 4, 62:1–62:10. Google ScholarDigital Library

11. Dubois, A., Grieve, K., Moneron, G., Lecaque, R., Vabre, L., and Boccara, C. 2004. Ultrahigh-resolution full-field optical coherence tomography. Appl. Opt. 43, 14 (May), 2874–2883.Google ScholarCross Ref

12. [email protected] http://www.fabathome.org/.Google Scholar

13. Fujifilm Dimatix. Dimatix materials printer dmp-2831.Google Scholar

14. GelSight. Gelsight benchtop scanner. http://http://www.gelsight.com/products/.Google Scholar

15. Han, L.-H., Suri, S., and Schmidt, C. E. 2010. Fabrication of three-dimensional scaffolds for heterogeneous tissue engineering. Biomed Microdevices 12, 721–725.Google ScholarCross Ref

16. Hašan, M., Fuchs, M., Matusik, W., Pfister, H., and Rusinkiewicz, S. 2010. Physical reproduction of materials with specified subsurface scattering. ACM Trans. Graph. 29, 4, 61:1–61:10. Google ScholarDigital Library

17. Hiller, J. D., and Lipson, H. 2012. Automatic design and manufacture of soft robots. IEEE Transactions on Robotics 28, 2, 457–466. Google ScholarDigital Library

18. Inamdar, A., Magana, M., Medina, F., Grajeda, Y., and Wicker, R. 2006. Development of an automated multiple material stereolithography machine. In Proceedings of 17th Annual Solid Freeform Fabrication Symposium, Austin, TX, 624âĂŞ–635.Google Scholar

19. Khalil, S., Nam, J., and Sun, W. 2005. Multi-nozzle deposition for construction of 3d biopolymer tissue scaffolds. Rapid Prototyping Journal 11, 1, 9–17.Google ScholarCross Ref

20. Kumar, P., Santosa, J. K., Beck, E., and Das, S. 2004. Direct-write deposition of fine powders through miniature hopper-nozzles for multi-material solid freeform fabrication. Rapid Prototyping Journal 10, 1, 14–23.Google ScholarCross Ref

21. Kwan, J. Design of Electronics for a High-resolution, Multi-Material, and Modular 3D Printer. Master’s thesis, Massachusetts Institute of Technology.Google Scholar

22. Lan, J. Design and Fabrication of a Modular Multi-Material 3D Printer. Master’s thesis, Massachusetts Institute of Technology.Google Scholar

23. L. E. Weiss, R. Merz, F. P. G. N. P. P. L. S. K. R. 1997. Shape deposition manufacturing of heterogeneous structures. Journal of Manufacturing Systems 16, 4.Google ScholarCross Ref

24. Lipton, J., Cohen, D., Heinz, M., Lobovsky, M., Parad, W., Bernstien, G., Li, T., Quartiere, J., Washington, K., Umaru, A., Masanoff, R., Granstein, J., Whitney, J., and Lipson, H. 2009. [email protected] Model 2: Towards Ubiquitous Personal Fabrication Devices. In Solid Freeform Fabrication Symposium (SFF’09), 70–81.Google Scholar

25. Makerbot. Replicator 2X http://www.makerbot.com/.Google Scholar

26. Maruo, S., Ikuta, K., and Ninagawa, T. 2001. Multi-polymer microstereolithography for hybrid opto-MEMS. In The 14th IEEE International Conference on Micro Electro Mechanical Systems, 151–154.Google Scholar

27. Oxman, N. 2011. Variable property rapid prototyping. Journal of Virtual and Physical Prototyping (VPP) 6, 1, 3–31.Google ScholarCross Ref

28. Papas, M., Jarosz, W., Jakob, W., Rusinkiewicz, S., Matusik, W., and Weyrich, T. 2011. Goal-based caustics. Computer Graphics Forum (Proc. Eurographics) 30, 2 (Apr.).Google ScholarCross Ref

29. Ramos, J. MultiFab: A Multi-material 3D Printing Platform. Master’s thesis, Massachusetts Institute of Technology.Google Scholar

30. Sachs, E., Cima, M., and Cornie, J. 1990. Three-dimensional printing: Rapid tooling and prototypes directly from a cad model. CIRP Annals-Manufacturing Technology 39, 1, 201–204.Google ScholarCross Ref

31. Skouras, M., Thomaszewski, B., Coros, S., Bickel, B., and Gross, M. 2013. Computational design of actuated deformable characters. ACM Trans. Graph. 32, 4 (July). Google ScholarDigital Library

32. Stratasys. Objet500 Connex Multi-Material 3D Printer http://www.stratasys.com/3D-Printers/design-series/precision/objet-connex500.Google Scholar

33. Szeliski, R. 2004. Image alignment and stitching: A tutorial. 89.Google Scholar

34. Tompkin, J., Heinzle, S., Kautz, J., and Matusik, W. 2013. Content-adaptive lenticular prints. ACM Trans. Graph. 32, 4 (July). Google ScholarDigital Library

35. Vidimč E, K., Wang, S.-P., Ragan-Kelley, J., and Matusik, W. 2013. OpenFab: A programmable pipeline for multi-material fabrication. ACM Trans. Graph. 32, 4 (July). Google ScholarDigital Library

36. Wang, L., Lau, J., Thomas, E. L., and Boyce, M. C. 2011. Co-continuous composite materials for stiffness, strength, and energy dissipation. Advanced Materials 23, 13, 1524–1529.Google ScholarCross Ref

37. Wetzstein, G., Lanman, D., Heidrich, W., and Raskar, R. 2011. Layered 3d: tomographic image synthesis for attenuation-based light field and high dynamic range displays. ACM Trans. Graph. 30, 4, 95. Google ScholarDigital Library

38. Willis, K. D. D., Brockmeyer, E., Hudson, S. E., and Poupyrev, I. 2012. Printed optics: 3D printing of embedded optical elements for interactive devices. In UIST. Google ScholarDigital Library

39. Zhao, S., Hasan, M., Ramamoorthi, R., and Bala, K. 2013. Modular flux transfer: efficient rendering of high-resolution volumes with repeated structures. ACM Trans. Graph. 32, 4, 131. Google ScholarDigital Library

40. Zhou, C., Chen, Y., Yang, Z., and Khoshnevis, B. 2013. Digital material fabrication using mask-image-projectionbased stereolithography. Rapid Prototyping Journal 19, 3, 153–165.Google ScholarCross Ref