“CofiFab: coarse-to-fine fabrication of large 3D objects”

Conference:

Type(s):

Title:

- CofiFab: coarse-to-fine fabrication of large 3D objects

Session/Category Title: FABRICATING STRUCTURE & APPEARANCE

Presenter(s)/Author(s):

Moderator(s):

Abstract:

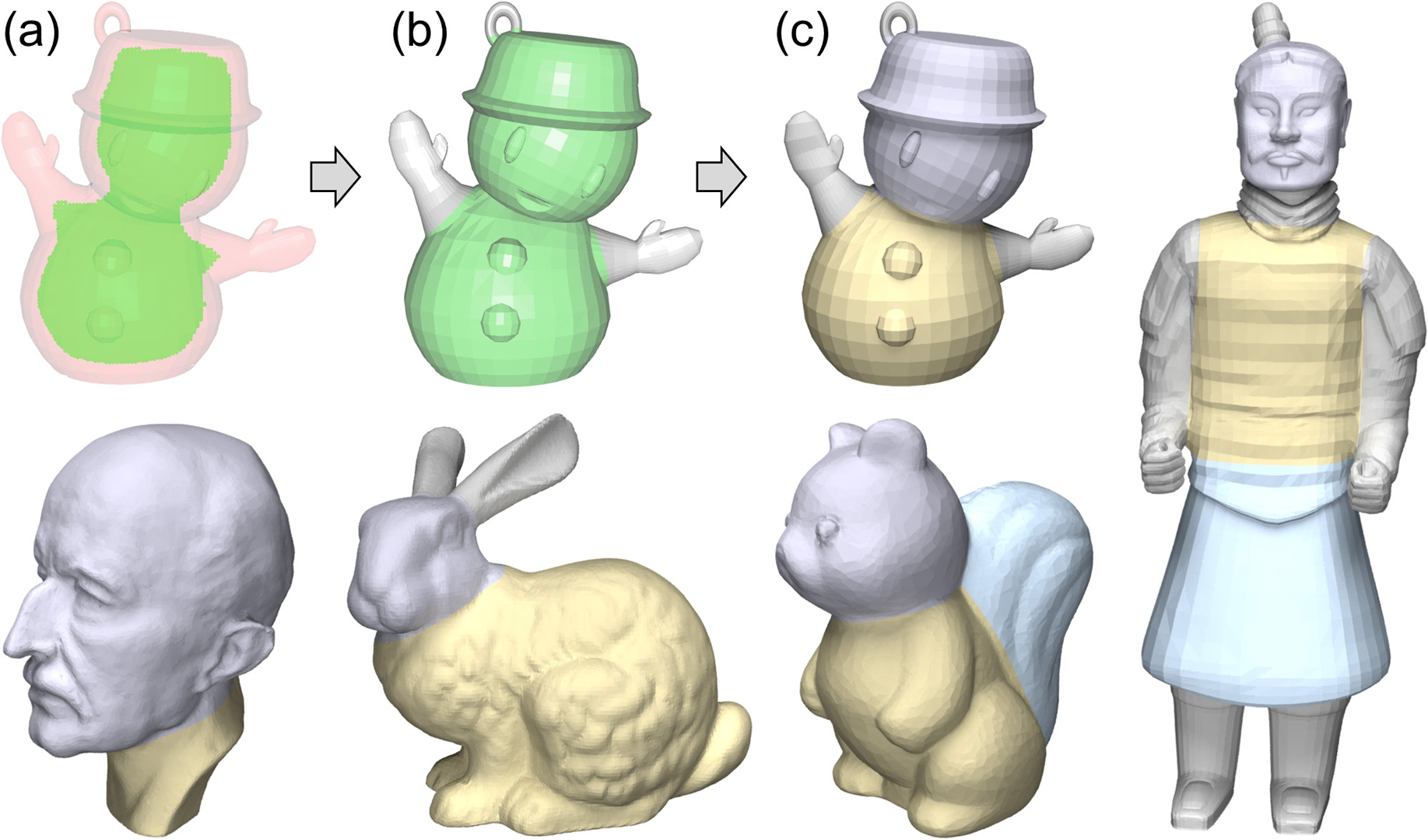

This paper presents CofiFab, a coarse-to-fine 3D fabrication solution, combining 3D printing and 2D laser cutting for cost-effective fabrication of large objects at lower cost and higher speed. Our key approach is to first build coarse internal base structures within the given 3D object using laser cutting, and then attach thin 3D-printed parts, as an external shell, onto the base to recover the fine surface details. CofiFab achieves this with three novel algorithmic components. First, we formulate an optimization model to compute fabricatable polyhedrons of maximized volume, as the geometry of the internal base. Second, we devise a new interlocking scheme to tightly connect the laser-cut parts into a strong internal base, by iteratively building a network of nonorthogonal joints and interlocking parts around polyhedral corners. Lastly, we optimize the partitioning of the external object shell into 3D-printable parts, while saving support material and avoiding overhangs. Besides cost saving, these components also consider aesthetics, stability and balancing. Hence, CofiFab can efficiently produce large objects by assembly. To evaluate CofiFab, we fabricate objects of varying shapes and sizes, and show that CofiFab can significantly outperform previous methods.

References:

1. Alemanno, G., Cignoni, P., Pietroni, N., Ponchio, F., and Scopigno, R. 2014. Interlocking pieces for printing tangible cultural heritage replicas. In Eurographics Workshop on Graphics and Cultural Heritage, 145–154. Google ScholarDigital Library

2. Alexandrov, A. D. 2005. Convex Polyhedra. Springer.Google Scholar

3. Beyer, D., Gurevich, S., Mueller, S., Chen, H.-T., and Baudisch, P. 2015. Platener: Low-fidelity fabrication of 3D objects by substituting 3D print with laser-cut plates. CHI ’15, 1799–1806. Google ScholarDigital Library

4. Borgefors, G., and Strand, R. 2005. An approximation of the maximal inscribed convex set of a digital object. In Image Analysis and Processing – ICIAP 2005. 438–445. Google ScholarDigital Library

5. Cabello, S., Cibulka, J., Kynčl, J., Saumell, M., and Valtr, P. 2014. Peeling potatoes near-optimally in near-linear time. SOCG’14, 224:224–224:231. Google ScholarDigital Library

6. Chang, J. S., and Yap, C. K. 1986. A polynomial solution for the potato-peeling problem. Discrete & Comp. Geom. 1, 2, 155–182. Google ScholarDigital Library

7. Chen, L., and Sass, L. 2015. Fresh Press Modeler: A generative system for physically based low fidelity prototyping. Computers & Graphics 54, 157–165. Google ScholarDigital Library

8. Chen, D., Sitthi-amorn, P., Lan, J. T., and Matusik, W. 2013. Computing and fabricating multiplanar models. Computer Graphics Forum 32, 2, 305–315.Google ScholarCross Ref

9. Chen, X., Zhang, H., Lin, J., Hu, R., Lu, L., Huang, Q., Benes, B., Cohen-Or, D., and Chen, B. 2015. Dapper: Decompose-and-pack for 3D printing. ACM Trans. Graph. 34, 6, 213:1–213:12. Google ScholarDigital Library

10. Cignoni, P., Pietroni, N., Malomo, L., and Scopigno, R. 2014. Field-aligned mesh joinery. ACM Trans. Graph. 33, 1, 11:1–11:12. Google ScholarDigital Library

11. Cohen-Steiner, D., Alliez, P., and Desbrun, M. 2004. Variational shape approximation. ACM Trans. Graph. 23, 3, 905–914. Google ScholarDigital Library

12. Craftsmansapce, 2015. Woodworking joints. http://www.craftsmanspace.com/knowledge/woodworking-joints.html.Google Scholar

13. Deits, R., and Tedrake, R. 2015. Computing large convex regions of obstacle-free space through semidefinite programming. In Algorithmic Foundations of Robotics XI. 109–124.Google Scholar

14. Fu, C.-W., Song, P., Yan, X., Yang, L. W., Jayaraman, P. K., and Cohen-Or, D. 2015. Computational interlocking furniture assembly. ACM Trans. Graph. 34, 4, 91:1–91:11. Google ScholarDigital Library

15. Gao, W., Zhang, Y., Nazzetta, D. C., Ramani, K., and Cipra, R. J. 2015. RevoMaker: Enabling multi-directional and functionally-embedded 3D printing using a rotational cuboidal platform. UIST ’15, 437–446. Google ScholarDigital Library

16. Gershenfeld, N. 2007. Fab: The Coming Revolution on Your Desktop–from Personal Computers to Personal Fabrication. Basic Books, Inc., New York, NY, USA. Google ScholarDigital Library

17. Goodman, J. E. 1981. On the largest convex polygon contained in a non-convex n-gon, or how to peel a potato. Geometriae Dedicata 11, 1, 99–106.Google ScholarCross Ref

18. Hao, J., Fang, L., and Williams, R. E. 2011. An efficient curvature-based partitioning of large-scale STL models. Rapid Prototyping Journal 17, 2, 116–127.Google ScholarCross Ref

19. Hildebrand, K., Bickel, B., and Alexa, M. 2012. crdbrd: Shape fabrication by sliding planar slices. Computer Graphics Forum 31, 2, 583–592. Google ScholarDigital Library

20. Hornus, S., Lefebvre, S., Dumas, J., and Claux, F. 2015. Tight printable enclosures for additive manufacturing. Tech. rep., Inria. RR-8712.Google Scholar

21. Hu, R., Li, H., Zhang, H., and Cohen-Or, D. 2014. Approximate pyramidal shape decomposition. ACM Trans. Graph. 33, 6, 213:1–213:12. Google ScholarDigital Library

22. Lien, J.-M., and Amato, N. M. 2008. Approximate convex decomposition of polyhedra and its applications. Comput. Aided Geom. Des. 25, 7, 503–522. Google ScholarDigital Library

23. Lu, L., Sharf, A., Zhao, H., Wei, Y., Fan, Q., Chen, X., Savoye, Y., Tu, C., Cohen-Or, D., and Chen, B. 2014. Build-to-last: Strength to weight 3D printed objects. ACM Trans. Graph. 33, 4, 97:1–97:10. Google ScholarDigital Library

24. Luo, L., Baran, I., Rusinkiewicz, S., and Matusik, W. 2012. Chopper: Partitioning models into 3D-printable parts. ACM Trans. Graph. 31, 6, 129:1–129:9. Google ScholarDigital Library

25. McCrae, J., Singh, K., and Mitra, N. J. 2011. Slices: A shape-proxy based on planar sections. ACM Trans. Graph. 30, 6, 168:1–168:12. Google ScholarDigital Library

26. Medellín, H., Lim, T., Corney, J., Ritchie, J. M., and Davies, J. B. C. 2007. Automatic subdivision and refinement of large components for rapid prototyping production. J. Comput. Inf. Sci. Eng. 7, 3, 249–258.Google ScholarCross Ref

27. Mueller, S., Mohr, T., Guenther, K., Frohnhofen, J., and Baudisch, P. 2014. faBrickation: Fast 3D printing of functional objects by integrating construction kit building blocks. CHI ’14, 3827–3834. Google ScholarDigital Library

28. Prévost, R., Whiting, E., Lefebvre, S., and Sorkine-Hornung, O. 2013. Make it stand: Balancing shapes for 3D fabrication. ACM Trans. Graph. 32, 4, 81:1–81:10. Google ScholarDigital Library

29. Schwartzburg, Y., and Pauly, M. 2013. Fabrication-aware design with intersecting planar pieces. Computer Graphics Forum 32, 2, 317–326.Google ScholarCross Ref

30. Song, P., Fu, C.-W., and Cohen-Or, D. 2012. Recursive interlocking puzzles. ACM Trans. Graph. 31, 6, 128:1–128:10. Google ScholarDigital Library

31. Song, P., Fu, Z., Liu, L., and Fu, C.-W. 2015. Printing 3D objects with interlocking parts. CAGD 35–36, 137–148. Google ScholarDigital Library

32. Stava, O., Vanek, J., Benes, B., Carr, N., and Měch, R. 2012. Stress relief: Improving structural strength of 3D printable objects. ACM Trans. Graph. 31, 4, 48:1–48:11. Google ScholarDigital Library

33. Vanek, J., Galicia, J. A. G., Benes, B., Měch, R., Carr, N., Stava, O., and Miller, G. S. 2014. PackMerger: A 3D print volume optimizer. Computer Graphics Forum 33, 6, 322–332.Google ScholarDigital Library

34. Wächter, A., and Biegler, L. T. 2006. On the implementation of an interior-point filter line-search algorithm for large-scale nonlinear programming. Math. Program. 106, 1, 25–57.Google ScholarCross Ref

35. Wang, W., Wang, T. Y., Yang, Z., Liu, L., Tong, X., Tong, W., Deng, J., Chen, F., and Liu, X. 2013. Cost-effective printing of 3D objects with skin-frame structures. ACM Trans. Graph. 32, 6, 177:1–177:10. Google ScholarDigital Library

36. Yao, M., Chen, Z., Luo, L., Wang, R., and Wang, H. 2015. Level-set-based partitioning and packing optimization of a printable model. ACM Trans. Graph. 34, 6, 214:1–214:11. Google ScholarDigital Library

37. Zhang, X., Xia, Y., Wang, J., Yang, Z., Tu, C., and Wang, W. 2015. Medial axis tree-an internal supporting structure for 3D printing. Comput. Aided Geom. Des. 35–36, 149–162. Google ScholarDigital Library