“Weaving Objects: Spatial Design and Functionality of 3D Woven Textiles” by Harvey, Holtzman, Kessler, Ko, Hagan, et al. …

Conference:

Type(s):

Title:

- Weaving Objects: Spatial Design and Functionality of 3D Woven Textiles

Presenter(s)/Author(s):

Abstract:

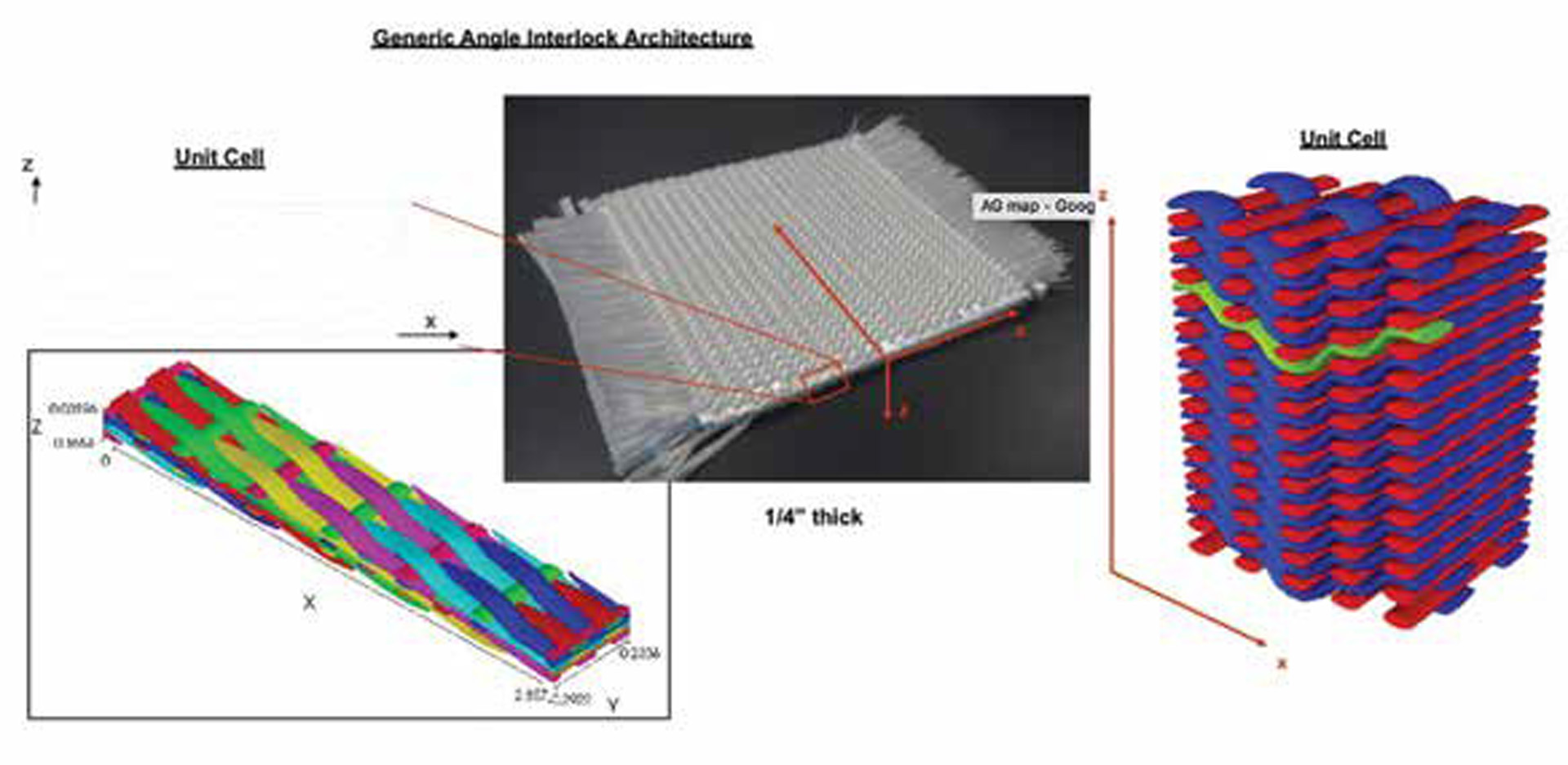

Our interdisciplinary design research group demonstrates a novel methodology and new computational tools to access 3D weaving as a spatial and material design platform for innovative softgoods and accessory products. We develop a fully formed 3D woven shoe and document volumetric textile behavior and simulation technology for creative design.

3D weaving is an industrial process for creating volumetric material through organized multiaxis interlacing of yarns. The overall complexity and rarity of 3D weaving have limited its market to aerospace and military applications. Current textile design software does not address the ease of iterating through physical trialing so necessary for designers to access this medium. This paper describes the development of a series of volumetric textile samples culminating in the creation of a fully formed shoe and the collaboration with computer scientists to develop a visualization tool that addresses the consumer accessory design opportunities for this medium.

References:

1. C. McHugh, “The Use of Recent Developments in Conventional Weaving & Shedding Technology to Create 3D One-Piece Woven Carbon Preforms,” published by the Society for the Advancement of Material and Process Engineering (SAMPE). Copyright 2009 by Sigmatex.

2. C. McHugh, “The Manufacture of One-Piece Woven Three-Dimensional Carbon-Fiber Nodal Structures,” published by the Society for the Advancement of Material and Process Engineering (SAMPE). Copyright 2010 by Sigmatex.

3. X. Chen, L.W. Taylor and L.J. Tsai, “An Overview on Fabrication of Three-Dimensional Woven Textile Preforms for Composites,” Textile Research Journal 81, No. 9, 932–944 (2011).

4. S.S. Badawi, “Development of the Weaving Machine and 3D Woven Spacer Fabric Structures for Lightweight Composites Materials,” PhD Thesis, Technical University of Dresden, Dresden, Germany, 2009.

5. J.W.S. Hearle and X. Chen. “3D Woven Preforms and Properties for Textile Composites,” Seventeenth International Conference on Composite Materials, Edinburgh, U.K., July 27–31 2009.

6. A.P. Mouritz et al., “Review of Applications for Advanced Three-Dimensional Fibre Textile Composites,” Composites Part A: Applied Science and Manufacturing 30, No. 12, 1445–1461 (1999).

7. K. Fukuta et al., Three-Dimensional Fabric, and Method and Loom Construction for the Production Thereof, patent No. USP 3834424A, 1974.

8. Pointcarre. 1988. Pointcarre. www.pointcarre.com, accessed 21 May 2019.

9. ScotWeave. 2019. ScotWeave. www.scotweave.com, accessed 21 May 2019.

10. Y. Wang, digital fabric mechanics analyzer, Kansas State University Department of Mechanical and Nuclear Engineering, Army Research contracts W911NF-05-2-0010, W911NF-08-2-0041.

11. P. Irawan, “Appearance of Woven Cloth,” PhD thesis, Cornell University, Ithaca, N.Y., 2008, AAI3295837.

12. J.M. Kaldor, D.L. James and S. Marschner, “Simulating Knitted Cloth at the Yarn Level,” ACM Transactions on Graphics 27, No. 3, 65:1–65:9 (Aug. 2008).

13. J. Leaf et al., “Interactive Design of Periodic Yarn-Level Cloth Patterns,” ACM Transactions on Graphics 37, No. 6, 202:1–202:14 (Nov. 2018).

14. E. Miguel et al., “Modeling and Estimation of Internal Friction in Cloth,” ACM Transactions on Graphics 32, No. 6, 212:1–212:10 (Nov. 2013).

Additional Images:

- 2019 Art Papers: Harvey_Weaving Objects: Spatial Design and Functionality of 3D-Woven Textiles

- 2019 Art Papers: Harvey_Weaving Objects: Spatial Design and Functionality of 3D-Woven Textiles