“Weavecraft: an interactive design and simulation tool for 3D weaving” by Wu, Zhang, Leaf, Hua, Qu, et al. …

Conference:

Type(s):

Title:

- Weavecraft: an interactive design and simulation tool for 3D weaving

Session/Category Title:

- Fabrication: Computational Design

Presenter(s)/Author(s):

Abstract:

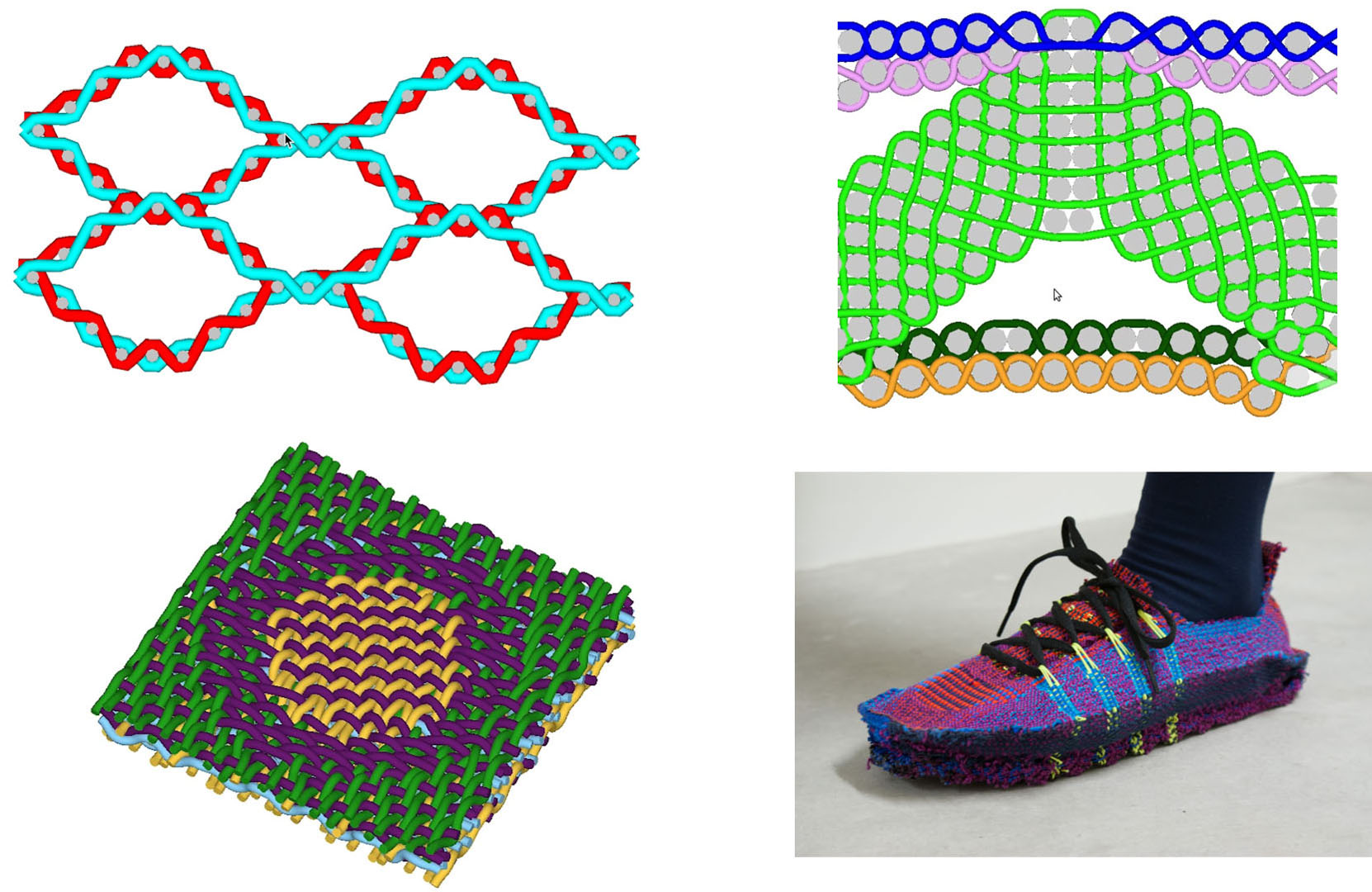

3D weaving is an emerging technology for manufacturing multilayer woven textiles. In this work, we present Weavecraft: an interactive, simulation-based design tool for 3D weaving. Unlike existing textile software that uses 2D representations for design patterns, we propose a novel weave block representation that helps the user to understand 3D woven structures and to create complex multi-layered patterns. With Weavecraft, users can create blocks either from scratch or by loading traditional weaves, compose the blocks into large structures, and edit the pattern at various scales. Furthermore, users can verify the design with a physically based simulator, which predicts and visualizes the geometric structure of the woven material and reveals potential defects at an interactive rate. We demonstrate a range of results created with our tool, from simple two-layer cloth and well known 3D structures to a more sophisticated design of a 3D woven shoe, and we evaluate the effectiveness of our system via a formative user study.

References:

1. Lea Albaugh, Scott Hudson, and Lining Yao. 2019. Digital fabrication of soft actuated objects by machine knitting. In Proceedings of the 2019 CHI Conference on Human Factors in Computing Systems. 1–13.Google ScholarDigital Library

2. Mahmood Ansar, Wang Xinwei, and Zhou Chouwei. 2011. Modeling strategies of 3D woven composites: a review. Composite structures 93, 8 (2011), 1947–1963.Google ScholarCross Ref

3. Bernd Bickel, Moritz Bächer, Miguel A Otaduy, Hyunho Richard Lee, Hanspeter Pfister, Markus Gross, and Wojciech Matusik. 2010. Design and fabrication of materials with desired deformation behavior. ACM Transactions on Graphics (TOG) 29, 4 (2010), 1–10.Google ScholarDigital Library

4. Xiaogang Chen. 2011. Mathematical modelling of 3D woven fabrics for CAD/CAM software. Textile Research Journal 81, 1 (2011), 42–50.Google ScholarCross Ref

5. Xiaogang Chen, Lindsay Waterton Taylor, and Li-Ju Tsai. 2011. An overview on fabrication of three-dimensional woven textile preforms for composites. Textile Research Journal 81, 9 (2011), 932–944.Google ScholarCross Ref

6. Gabriel Cirio, Jorge Lopez-Moreno, David Miraut, and Miguel A. Otaduy. 2014. Yarn-Level 7. Simulation of Woven Cloth. ACM Trans. on Graphics (Proc. of ACM SIGGRAPH Asia) 33, 6 (2014). http://www.gmrv.es/Publications/2014/CLMO14Google Scholar

7. Gabriel Cirio, Jorge Lopez-Moreno, and Miguel A Otaduy. 2015. Efficient simulation of knitted cloth using persistent contacts. In Proceedings of the 14th ACM SIGGRAPH/Eurographics Symposium on Computer Animation. ACM, 55–61.Google ScholarDigital Library

8. Gabriel Cirio, Jorge Lopez-Moreno, and Miguel A Otaduy. 2016. Yarn-level cloth simulation with sliding persistent contacts. IEEE transactions on visualization and computer graphics 23, 2 (2016), 1152–1162.Google Scholar

9. BP Dash, BK Behera, Rajesh Mishra, and Jiri Militky. 2013. Modeling of internal geometry of 3D woven fabrics by computation method. Journal of The Textile Institute 104, 3 (2013), 312–321.Google ScholarCross Ref

10. GmbH EAT. 2015. 3DWeave | EAT GMBH – The Designscope Company. http://designscopecompany.com/3dweave/Google Scholar

11. Mikhaila Friske, Shanel Wu, and Laura Devendorf. 2019. AdaCAD: Crafting Software For Smart Textiles Design. In Proceedings of the 2019 CHI Conference on Human Factors in Computing Systems. 1–13.Google ScholarDigital Library

12. Ruben Geerinck, Ives De Baere, Geert De Clercq, Jan Ivens, and Joris Degrieck. 2016. Development and characterization of composites consisting of woven fabrics with integrated prismatic shaped cavities. In 3D fabrics and their applications.Google Scholar

13. Nur Al-huda Hamdan, Simon Voelker, and Jan Borchers. 2018. Sketch&Stitch: Interactive Embroidery for E-textiles. In Proceedings of the 2018 CHI Conference on Human Factors in Computing Systems. 1–13.Google ScholarDigital Library

14. Claire Harvey, Emily Holtzman, Joy Ko, Brooks Hagan, Rundong Wu, Steve Marschner, and David Kessler. 2019. Weaving objects: spatial design and functionality of 3D-woven textiles. Leonardo 52, 4 (2019), 381–388.Google ScholarCross Ref

15. Megan Hofmann, Lea Albaugh, Ticha Sethapakadi, Jessica Hodgins, Scott E Hudson, James McCann, and Jennifer Mankoff. 2019. KnitPicking Textures: Programming and Modifying Complex Knitted Textures for Machine and Hand Knitting. In Proceedings of the 32nd Annual ACM Symposium on User Interface Software and Technology. 5–16.Google ScholarDigital Library

16. Lejian Huang, Youqi Wang, Yuyang Miao, Daniel Swenson, Ying Ma, and Chian-Fong Yen. 2013. Dynamic relaxation approach with periodic boundary conditions in determining the 3-D woven textile micro-geometry. Composite Structures 106 (2013), 417–425.Google ScholarCross Ref

17. Yuki Igarashi, Takeo Igarashi, and Hiromasa Suzuki. 2008a. Knitting a 3D model. In Computer Graphics Forum, Vol. 27. Wiley Online Library, 1737–1743.Google Scholar

18. Yuki Igarashi, Takeo Igarashi, and Hiromasa Suzuki. 2008b. Knitty: 3D Modeling of Knitted Animals with a Production Assistant Interface.. In Eurographics (Short Papers). Citeseer, 17–20.Google Scholar

19. N Isart, B El Said, DS Ivanov, SR Hallett, JA Mayugo, and N Blanco. 2015. Internal geometric modelling of 3D woven composites: A comparison between different approaches. Composite Structures 132 (2015), 1219–1230.Google ScholarCross Ref

20. Jonathan M. Kaldor, Doug L. James, and Steve Marschner. 2008. Simulating Knitted Cloth at the Yarn Level. ACM T. Graph. (SIGGRAPH’08) 27, 3 (2008), 65.Google Scholar

21. Jonathan M Kaldor, Doug L James, and Steve Marschner. 2010. Efficient yarn-based cloth with adaptive contact linearization. In ACM Transactions on Graphics (TOG), Vol. 29. ACM, 105.Google ScholarDigital Library

22. Alexandre Kaspar, Tae-Hyun Oh, Liane Makatura, Petr Kellnhofer, Jacqueline Aslarus, and Wojciech Matusik. 2019. Neural Inverse Knitting: From Images to Manufacturing Instructions. arXiv preprint arXiv:1902.02752 (2019).Google Scholar

23. Konstantin Klamka, Raimund Dachselt, and Jürgen Steimle. 2020. Rapid Iron-On User Interfaces: Hands-on Fabrication of Interactive Textile Prototypes. In Proceedings of the 2020 CHI Conference on Human Factors in Computing Systems. 1–14.Google ScholarDigital Library

24. Jonathan Leaf, Rundong Wu, Eston Schweickart, Doug L James, and Steve Marschner. 2018. Interactive design of periodic yarn-level cloth patterns. In SIGGRAPH Asia 2018 Technical Papers. ACM, 202.Google Scholar

25. Minchen Li. 2018. FoldSketch: Enriching garments with physically reproducible folds. Ph.D. Dissertation. University of British Columbia.Google Scholar

26. Hua Lin, Martin Sherburn, Jonathan Crookston, Andrew C Long, Mike J Clifford, and I Arthur Jones. 2008. Finite element modelling of fabric compression. Modelling and Simulation in Materials Science and Engineering 16, 3 (2008), 035010.Google ScholarCross Ref

27. James McCann, Lea Albaugh, Vidya Narayanan, April Grow, Wojciech Matusik, Jennifer Mankoff, and Jessica Hodgins. 2016. A compiler for 3D machine knitting. ACM Transactions on Graphics (TOG) 35, 4 (2016), 49.Google ScholarDigital Library

28. Yuyang Miao, Eric Zhou, Youqi Wang, and Bryan A Cheeseman. 2008. Mechanics of textile composites: Micro-geometry. Composites Science and Technology 68, 7–8 (2008), 1671–1678.Google ScholarCross Ref

29. AP Mouritz, MK Bannister, PJ Falzon, and KH Leong. 1999. Review of applications for advanced three-dimensional fibre textile composites. Composites Part A: Applied science and manufacturing 30, 12 (1999), 1445–1461.Google Scholar

30. MultiMechanics. 2018. Product. http://multimechanics.com/product/Google Scholar

31. Vidya Narayanan, Lea Albaugh, Jessica Hodgins, Stelian Coros, and James Mccann. 2018. Automatic Machine Knitting of 3D Meshes. ACM Trans. Graph. 37, 3, Article 35 (Aug. 2018), 15 pages. Google ScholarDigital Library

32. Vidya Narayanan, Kui Wu, Cem Yuksel, and James McCann. 2019. Visual knitting machine programming. ACM Transactions on Graphics (TOG) 38, 4 (2019), 1–13.Google ScholarDigital Library

33. Saad Nauman and Irina Cristian. 2015. Geometrical modelling of orthogonal/layer-to-layer woven interlock carbon reinforcement. The Journal of The Textile Institute 106, 7 (2015), 725–735.Google ScholarCross Ref

34. Jesús Pérez, Miguel A Otaduy, and Bernhard Thomaszewski. 2017. Computational design and automated fabrication of kirchhoff-plateau surfaces. ACM Transactions on Graphics (TOG) 36, 4 (2017), 1–12.Google ScholarDigital Library

35. Pointcarre. 1988. Pointcarre. http://www.pointcarre.com/.Google Scholar

36. Ivan Poupyrev, Nan-Wei Gong, Shiho Fukuhara, Mustafa Emre Karagozler, Carsten Schwesig, and Karen E Robinson. 2016. Project Jacquard: interactive digital textiles at scale. In Proceedings of the 2016 CHI Conference on Human Factors in Computing Systems. 4216–4227.Google ScholarDigital Library

37. Michael L Rivera, Melissa Moukperian, Daniel Ashbrook, Jennifer Mankoff, and Scott E Hudson. 2017. Stretching the bounds of 3D printing with embedded textiles. In Proceedings of the 2017 CHI Conference on Human Factors in Computing Systems. 497–508.Google ScholarDigital Library

38. ScotWeave. 2019. ScotWeave. http://www.scotweave.com/.Google Scholar

39. Martin Sherburn. 2007. Geometric and mechanical modelling of textiles. Ph.D. Dissertation. University of Nottingham.Google Scholar

40. Shinjiro Sueda, Garrett L Jones, David IW Levin, and Dinesh K Pai. 2011. Large-scale dynamic simulation of highly constrained strands. In ACM SIGGRAPH 2011 papers. 1–10.Google ScholarDigital Library

41. Muhammad Umair, Yasir Nawab, Mumtaz Hasan Malik, and Khubab Shaker. 2015. Development and characterization of three-dimensional woven-shaped preforms and their associated composites. Journal of Reinforced Plastics and Composites 34, 24 (2015), 2018–2028.Google ScholarCross Ref

42. Nobuyuki Umetani, Danny M Kaufman, Takeo Igarashi, and Eitan Grinspun. 2011. Sensitive couture for interactive garment modeling and editing. ACM Trans. Graph. 30, 4 (2011), 90.Google ScholarDigital Library

43. Kiril Vidimce, Alexandre Kaspar, Ye Wang, and Wojciech Matusik. 2016. Foundry: Hierarchical material design for multi-material fabrication. In Proceedings of the 29th Annual Symposium on User Interface Software and Technology. 563–574.Google ScholarDigital Library

44. Pascal Volino, Nadia Magnenat-Thalmann, and Francois Faure. 2009. A simple approach to nonlinear tensile stiffness for accurate cloth simulation. (2009).Google Scholar

45. Kui Wu, Xifeng Gao, Zachary Ferguson, Daniele Panozzo, and Cem Yuksel. 2018. Stitch meshing. ACM Transactions on Graphics (TOG) 37, 4 (2018), 130.Google ScholarDigital Library

46. Kui Wu, Hannah Swan, and Cem Yuksel. 2019. Knittable stitch meshes. ACM Transactions on Graphics (TOG) 38, 1 (2019), 1–13.Google ScholarDigital Library

47. Rundong Wu, Claire Harvey, Joy Xiaoji Zhang, Sean Kroszner, Brooks Hagan, and Steve Marschner. 2020. Automatic Structure Synthesis for 3D Woven Relief. ACM Transcations on Graphics (TOG) 39, 4.Google Scholar

48. Joanne Yip and Sun-Pui Ng. 2008. Study of three-dimensional spacer fabrics:: Physical and mechanical properties. Journal of materials processing technology 206, 1–3 (2008), 359–364.Google ScholarCross Ref

49. Cem Yuksel, Jonathan M Kaldor, Doug L James, and Steve Marschner. 2012. Stitch meshes for modeling knitted clothing with yarn-level detail. ACM Transactions on Graphics (TOG) 31, 4 (2012), 37.Google ScholarDigital Library

50. Shuang Zhao, Fujun Luan, and Kavita Bala. 2016. Fitting procedural yarn models for realistic cloth rendering. ACM Transactions on Graphics (TOG) 35, 4 (2016), 51.Google ScholarDigital Library