“Cost-effective printing of 3D objects with skin-frame structures” by Wang, Wang, Yang, Liu, Tong, et al. …

Conference:

Type(s):

Title:

- Cost-effective printing of 3D objects with skin-frame structures

Session/Category Title: Modeling Primitives

Presenter(s)/Author(s):

Abstract:

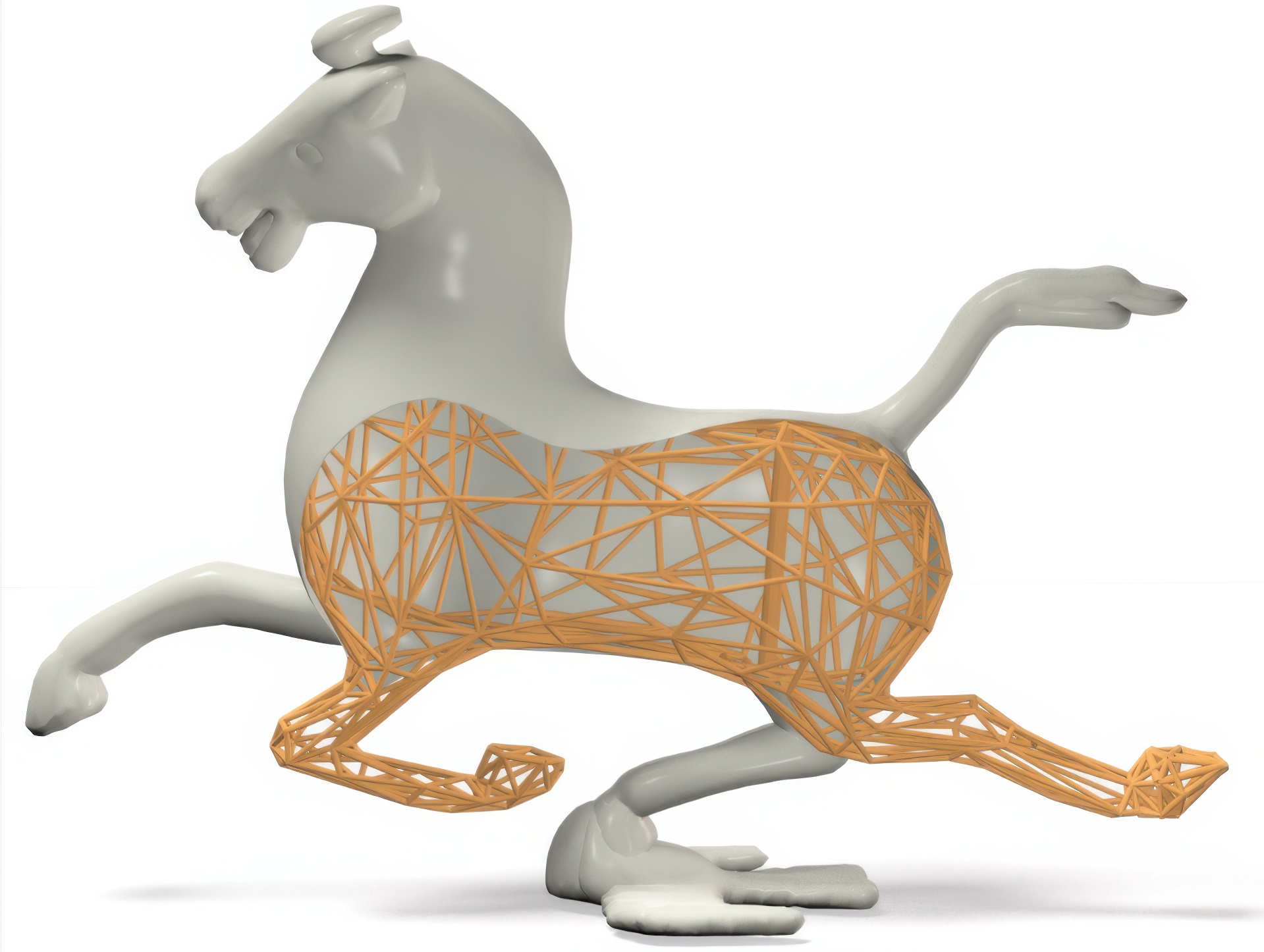

3D printers have become popular in recent years and enable fabrication of custom objects for home users. However, the cost of the material used in printing remains high. In this paper, we present an automatic solution to design a skin-frame structure for the purpose of reducing the material cost in printing a given 3D object. The frame structure is designed by an optimization scheme which significantly reduces material volume and is guaranteed to be physically stable, geometrically approximate, and printable. Furthermore, the number of struts is minimized by solving an l0 sparsity optimization. We formulate it as a multi-objective programming problem and an iterative extension of the preemptive algorithm is developed to find a compromise solution. We demonstrate the applicability and practicability of our solution by printing various objects using both powder-type and extrusion-type 3D printers. Our method is shown to be more cost-effective than previous works.

References:

1. 3DSystems, 2012. Desktop 3D printer. http://www.3dsystems.com.

2. Arya, S., Mount, D. M., Netanyahu, N. S., Silverman, R., and Wu, A. Y. 1998. An optimal algorithm for approximate nearest neighbor searching fixed dimensions. Journal of the ACM 45, 6, 891–923.

3. Bächer, M., Bickel, B., James, D. L., and Pfister, H. 2012. Fabricating articulated characters from skinned meshes. ACM Trans. Graph. (Proc. SIGGRAPH) 31, 4, 47:1–9.

4. Bendsøe, M. P., and Sigmund, O. 2003. Topology optimization: theory, methods and applications. Springer Verlag.

5. Bendsøe, M. P., Ben-Tal, A., and Zowe, J. 1994. Optimization methods for truss geometry and topology design. Structural Optimization 7, 3, 141–159.

6. Calì, J., Calian, D., Amati, C., Kleinberger, R., Steed, A., Kautz, J., and Weyrich, T. 2012. 3D-printing of non-assembly, articulated models. ACM Trans. Graph. (Proc. SIGGRAPH Asia) 31, 6, 130:1–8.

7. Chen, D., Levin, D. I. W., Didyk, P., Sitthi-Amorn, P., and Matusik, W. 2013. Spec2Fab: a reducer-tuner model for translating specifications to 3D prints. ACM Trans. Graph. (Proc. SIGGRAPH) 32, 4, 135:1–135:10.

8. Chen, Y. 2007. 3D texture mapping for rapid manufacturing. Computer-Aided Design and Applications 4, 6, 761–771.

9. Cheng, G. 1995. Some aspects of truss topology optimization. Structural Optimization 10, 3–4, 173–179.

10. Gibson, L. J., and Ashby, M. F. 1999. Cellular Solids: Structure and Properties, 2nd ed. Cambridge University Press.

11. Hughes, T. J. R. 1987. The Finite Element Method: Linear Static and Dynamic Finite Element Analysis. Prentice-Hall.

12. Kirsch, U. 1989. Optimal topologies of structures. Applied Mechanics Reviews 42, 223–238.

13. Luo, L., Baran, I., Rusinkiewicz, S., and Matusik, W. 2012. Chopper: partitioning models into 3D-printable parts. ACM Trans. Graph. (Proc. SIGGRAPH Asia) 31, 6, 129:1–9.

14. Makerbot, 2012. Rapid prototyping and 3D printing. http://www.makerbot.com/.

15. Nocedal, J., and Wright, S. 2006. Numerical Optimization, 2nd ed. Springer.

16. Prévost, R., Whiting, E., Lefebvre, S., and SorkineHornung, O. 2013. Make it stand: balancing shapes for 3D fabrication. ACM Trans. Graph. (Proc. SIGGRAPH) 32, 4, 81:1–81:10.

17. Rajeev, S., and Krishnamoorthy, C. 1997. Genetic algorithms-based methodologies for design optimization of trusses. Journal of Structural Engineering 123, 3, 350–358.

18. Rosen, D. W., Johnston, S. R., and Reed, M. 2006. Design of general lattice structures for lightweight and compliance applications. In Proc. Rapid Manufacturing Conference, 1–14.

19. Shapeways, 2012. Tutorial: How to hollow objects for 3D printing. http://www.shapeways.com/tutorials/creating-hollow-objects.html.

20. Smith, J., Hodgins, J., Oppenheim, I., and Witkin, A. 2002. Creating models of truss structures with optimization. ACM Trans. Graph. (Proc. SIGGRAPH) 21, 3, 295–301.

21. Stava, O., Vanek, J., Benes, B., Carr, N., and Měch, R. 2012. Stress relief: improving structural strength of 3D printable objects. ACM Trans. Graph. (Proc. SIGGRAPH) 31, 4, 48:1–11.

22. Taubin, G. 1995. A signal processing approach to fair surface design. In Proc. SIGGRAPH, 351–358.

23. Wang, H., and Rosen, D. W. 2002. Parametric modeling method for truss structures. In Proc. ASME Design Engineering Technical Conferences, ASME, NY, USA, 759–767.

24. Wang, H., Chen, Y., and Rosen, D. W. 2005. A hybrid geometric modeling method for large scale conformal cellular structures. In Proc. ASME Design Engineering Technical Conferences, ASME, NY, USA, 421–427.

25. Yan, D.-M., Lévy, B., Liu, Y., Sun, F., and Wang, W. 2009. Isotropic remeshing with fast and exact computation of restricted voronoi diagram. Computer Graphics Forum 28, 5, 1445–1454.

26. Zhou, Q., Panetta, J., and Zorin, D. 2013. Worst-case structural analysis. ACM Trans. Graph. (Proc. SIGGRAPH) 32, 4, 137:1–137:12.