“3D-printing of non-assembly, articulated models” by Calì, Calian, Amati, Kleinberger, Steed, et al. …

Conference:

Type(s):

Title:

- 3D-printing of non-assembly, articulated models

Session/Category Title:

- Physical Models

Presenter(s)/Author(s):

Abstract:

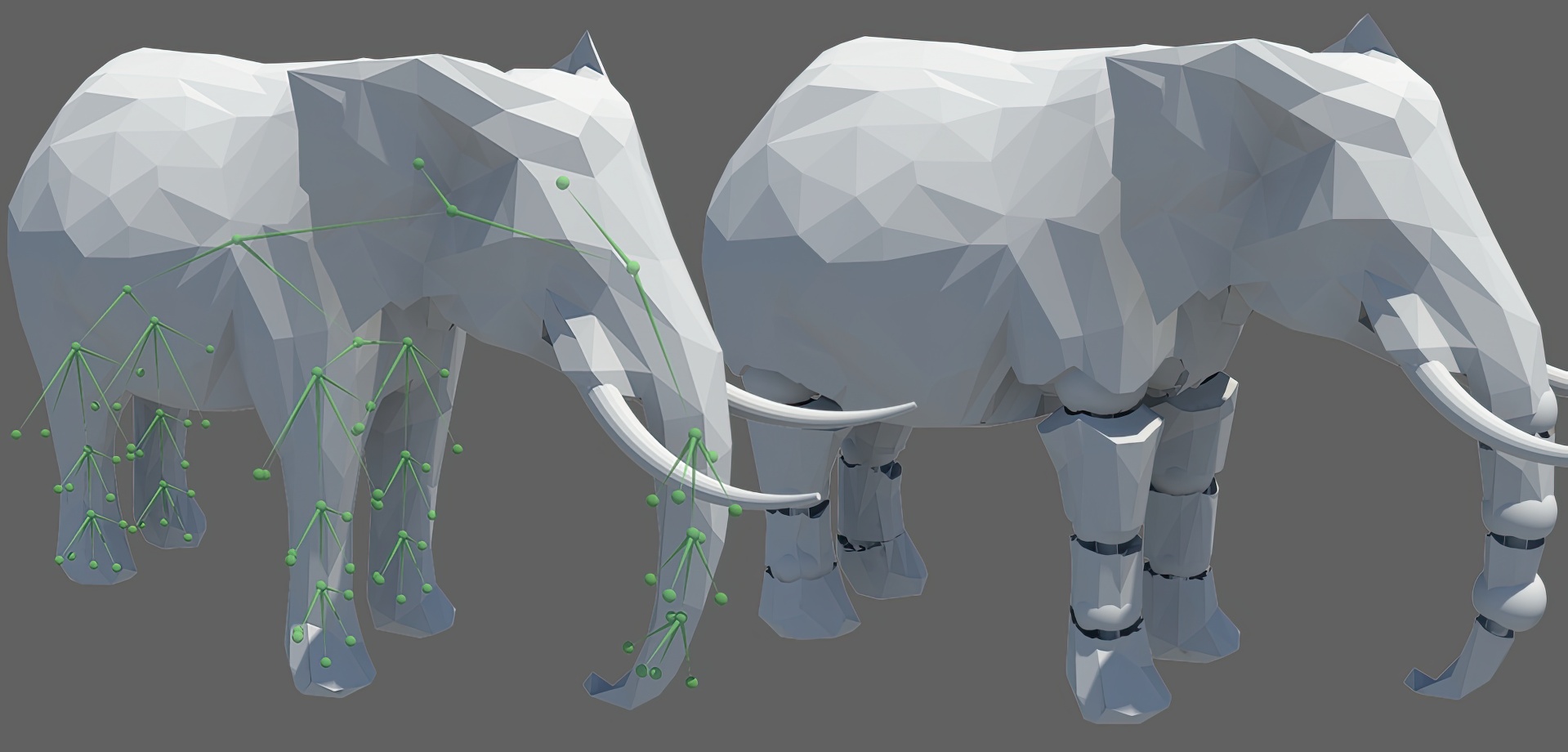

Additive manufacturing (3D printing) is commonly used to produce physical models for a wide variety of applications, from archaeology to design. While static models are directly supported, it is desirable to also be able to print models with functional articulations, such as a hand with joints and knuckles, without the need for manual assembly of joint components. Apart from having to address limitations inherent to the printing process, this poses a particular challenge for articulated models that should be posable: to allow the model to hold a pose, joints need to exhibit internal friction to withstand gravity, without their parts fusing during 3D printing. This has not been possible with previous printable joint designs. In this paper, we propose a method for converting 3D models into printable, functional, non-assembly models with internal friction. To this end, we have designed an intuitive work-flow that takes an appropriately rigged 3D model, automatically fits novel 3D-printable and posable joints, and provides an interface for specifying rotational constraints. We show a number of results for different articulated models, demonstrating the effectiveness of our method.

References:

1. Alavala, C. R. 2010. CAD/CAM: Concepts and Applications. Prentice-Hall.

2. Autodesk, 2012. Maya User Guide: Rigging.

3. Bächer, M., Bickel, B., James, D. L., and Pfister, H. 2012. Fabricating articulated characters from skinned meshes. ACM Trans. Graph. (Proc. SIGGRAPH) 31, 4 (July), 47:1–47:9.

4. Bailey, M. 2005. Layered manufacturing for scientific visualization. Commun. ACM 48, 6 (June), 42–48.

5. Bickel, B., Bächer, M., Otaduy, M. A., Lee, H. R., Pfister, H., Gross, M., and Matusik, W. 2010. Design and fabrication of materials with desired deformation behavior. ACM Trans. Graph. 29, 4 (July), 63:1–63:10.

6. Chen, Y., and Zhezheng, C. 2011. Joint analysis in rapid fabrication of non-assembly mechanisms. Rapid Prototyping Journal 17, 6, 408–417.

7. Dimitrov, D., Schreve, K., and de Beer, N. 2006. Advances in three dimensional printing state of the art and future perspectives. Rapid Prototyping Journal 12, 136–147.

8. FigurePrints LLC, 2012. Figureprints. http://www.figureprints.com.

9. Fischler, M., and Bolles, R. 1981. Random sample consensus: a paradigm for model fitting with applications to image analysis and automated cartography. Communications of the ACM 24, 6, 381–395.

10. Gibson, I., Rosen, D. W., and Stucke, B. 2009. Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing. Springer.

11. Kodama Studios, 2012. My robot nation. http://www.myrobotnation.com/.

12. Lau, M., Ohgawara, A., Mitani, J., and Igarashi, T. 2011. Converting 3D furniture models to fabricatable parts and connectors. ACM Trans. Graph. 30, 4 (Aug.), 85:1–85:6.

13. Laurentis, K. J. D., and Mavroidis, C. 2004. Rapid fabrication of a non-assembly robotic hand with embedded components. Assembly Automation, 24, 394–405.

14. Lee, K. 1999. Principles of CAD/CAM/CAE Systems. Prentice Hall.

15. Leondes, C. T., Ed. 2003. Computer Aided and Integrated Manufacturing Systems, Volume 4: Computer Aided Design/Computer Aided Manufacturing (CAD/CAM). World Scientific.

16. Lipson, H., and Pollack, J. B. 2000. Automatic design and manufacture of robotic lifeforms. Nature 406, 6799, 974–978.

17. Lipson, H., Moon, F., Hai, J., and Paventi, C. 2005. 3-d printing the history of mechanisms. Journal of Mechanical Design 127, 123–132.

18. Lo, K.-Y., Fu, C.-W., and Li, H. 2009. 3D polyomino puzzle. ACM Trans. Graph. 28, 5 (Dec.), 157:1–157:8.

19. MakieLab, 2012. MakieLab. http://www.makielab.com/.

20. Mavroidis, C., DeLaurentis, K., Won, J., and Alam, M. 2001. Fabrication of non-assembly mechanisms and robotic systems using rapid prototyping. ASME Journal of Mechanical Design 123, 4, 516–524.

21. McMains, S., Bailey, M., and Crawford, R. 2005. Layered manufacturing as a graphics display device. In ACM SIGGRAPH 2005 Courses, ACM, New York, NY, USA, SIGGRAPH ’05.

22. Mitra, N. J., and Pauly, M. 2009. Shadow art. ACM Trans. Graph. 28, 5 (Dec.), 156:1–156:7.

23. Mitra, N. J., Yang, Y.-L., Yan, D.-M., Li, W., and Agrawala, M. 2010. Illustrating how mechanical assemblies work. ACM Trans. Graph. 29 (July), 58:1–58:12.

24. Rajagopalan, S., and Cutkosky, M. 2003. Error analysis for the in-situ fabrication of mechanisms. Journal of Mechanical Design 125, 4, 809–822.

25. Shoemake, K. 1985. Animating rotation with quaternion curves. ACM SIGGRAPH computer graphics 19, 3, 245–254.

26. Sims, K. 1994. Evolving virtual creatures. In Proceedings of the 21st annual conference on Computer graphics and interactive techniques, ACM, New York, NY, USA, SIGGRAPH ’94, 15–22.

27. Stava, O., Vanek, J., Benes, B., Carr, N., and Měch, R. 2012. Stress relief: improving structural strength of 3D printable objects. ACM Trans. Graph. (Proc. SIGGRAPH) 31, 4 (July), 48:1–48:11.

28. Stemp-Morlock, G. 2010. Personal fabrication. Commun. ACM 53, 10 (Oct.), 14–15.

29. Thingiverse, 2012. http://www.thingiverse.com/search?q=gears.

30. Thompson, R. 2007. Manufacturing Processes for Design Professionals. Thames & Hudson.

31. Won, J., Laurentis, K. J. D., and Mavroidis, C. 2000. Rapid prototyping of robotic systems. In ICRA, IEEE, 3077–3082.

32. Xin, S., Lai, C.-F., Fu, C.-W., Wong, T.-T., He, Y., and Cohen-Or, D. 2011. Making burr puzzles from 3D models. ACM Transactions on Graphics (SIGGRAPH 2011 issue) 30, 4 (August), 97:1–97:8.

33. Xu, W., Wang, J., Yin, K., Zhou, K., van de Panne, M., Chen, F., and Guo, B. 2009. Joint-aware manipulation of deformable models. ACM Trans. Graph. 28, 3 (July), 35:1–35:9.