“Fitting procedural yarn models for realistic cloth rendering”

Conference:

Type(s):

Title:

- Fitting procedural yarn models for realistic cloth rendering

Session/Category Title: CLOTH

Presenter(s)/Author(s):

Moderator(s):

Abstract:

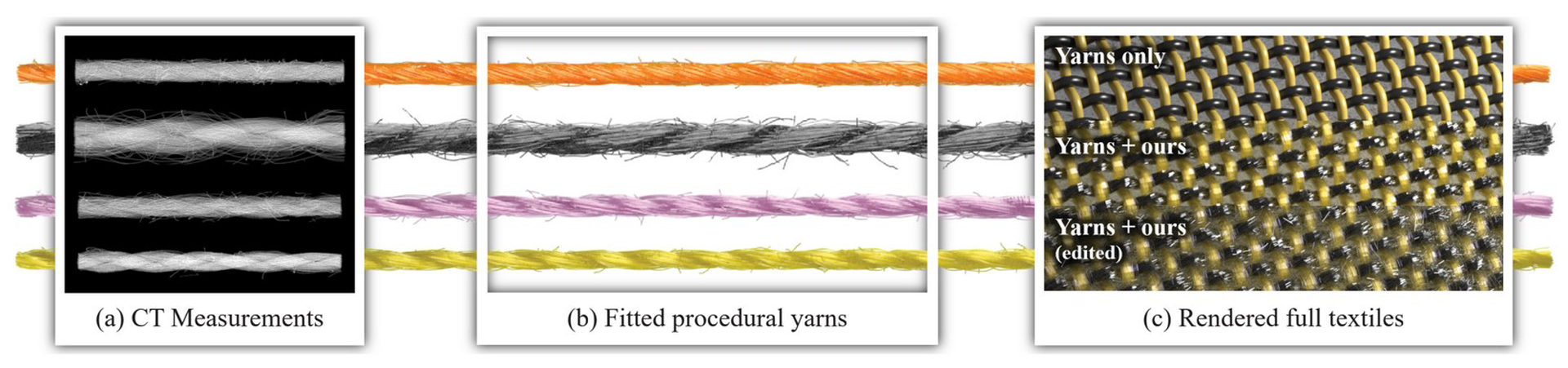

Fabrics play a significant role in many applications in design, prototyping, and entertainment. Recent fiber-based models capture the rich visual appearance of fabrics, but are too onerous to design and edit. Yarn-based procedural models are powerful and convenient, but too regular and not realistic enough in appearance. In this paper, we introduce an automatic fitting approach to create high-quality procedural yarn models of fabrics with fiber-level details. We fit CT data to procedural models to automatically recover a full range of parameters, and augment the models with a measurement-based model of flyaway fibers. We validate our fabric models against CT measurements and photographs, and demonstrate the utility of this approach for fabric modeling and editing.

References:

1. Cirio, G., Lopez-Moreno, J., Miraut, D., and Otaduy, M. A. 2014. Yarn-level simulation of woven cloth. ACM Trans. Graph. 33, 6, 207:1–207:11. Google ScholarDigital Library

2. Derouet-Jourdan, A., Bertails-Descoubes, F., and Thollot, J. 2013. Floating tangents for approximating spatial curves with G1 piecewise helices. Computer Aided Geometric Design 30, 5, 490–520. Google ScholarDigital Library

3. Hutt, M., 2011. C++ implementation of the Nelder-Mead simplex method. http://www.mikehutt.com/neldermead.html.Google Scholar

4. Irawan, P., and Marschner, S. 2012. Specular reflection from woven cloth. ACM Trans. Graph. 31, 1, 11:1–11:20. Google ScholarDigital Library

5. Jakob, W., Arbree, A., Moon, J. T., Bala, K., and Marschner, S. 2010. A radiative transfer framework for rendering materials with anisotropic structure. ACM Trans. Graph. 29, 4, 53:1–53:13. Google ScholarDigital Library

6. Jakob, W., 2013. Mitsuba renderer. http://www.mitsuba-renderer.org.Google Scholar

7. Kaldor, J. M., James, D. L., and Marschner, S. 2008. Simulating knitted cloth at the yarn level. ACM Trans. Graph. 27, 3, 65:1–65:9. Google ScholarDigital Library

8. Keefe, M. 1994. Solid modeling applied to fibrous assemblies. Part I: Twisted yarns. Journal of the Textile Institute 85, 3, 338–349.Google ScholarCross Ref

9. Khungurn, P., Schroeder, D., Zhao, S., Bala, K., and Marschner, S. 2015. Matching real fabrics with micro-appearance models. ACM Trans. Graph. 35, 1, 1:1–1:26. Google ScholarDigital Library

10. Morris, P., Merkin, J., and Rennell, R. 1999. Modelling of yarn properties from fibre properties. Journal of the Textile Institute. Part 1, Fibre science and textile technology 90, 3, 322–335.Google Scholar

11. Nelder, J. A., and Mead, R. 1965. A simplex method for function minimization. The computer journal 7, 4, 308–313.Google Scholar

12. Pointcarré, 2016. Pointcarré textile software. http://www.pointcarre.com.Google Scholar

13. Sadeghi, I., Bisker, O., De Deken, J., and Jensen, H. W. 2013. A practical microcylinder appearance model for cloth rendering. ACM Trans. Graph. 32, 2, 14:1–14:12. Google ScholarDigital Library

14. Schröder, K., Zinke, A., and Klein, R. 2015. Image-based reverse engineering and visual prototyping of woven cloth. Visualization and Computer Graphics, IEEE Transactions on 21, 2, 188–200.Google ScholarDigital Library

15. Shinohara, T., Takayama, J.-y., Ohyama, S., and Kobayashi, A. 2010. Extraction of yarn positional information from a three-dimensional CT Image of textile fabric using yarn tracing with a filament model for structure analysis. Textile Research Journal 80, 7, 623–630.Google ScholarCross Ref

16. Tao, X. 1996. Mechanical properties of a migrating fiber. Textile research journal 66, 12, 754–762.Google Scholar

17. Voborova, J., Garg, A., Neckar, B., and Ibrahim, S. 2004. Yarn properties measurement: an optical approach. In 2nd International textile, clothing and design conference, 1–6.Google Scholar

18. Xu, Y.-Q., Chen, Y., Lin, S., Zhong, H., Wu, E., Guo, B., and Shum, H.-Y. 2001. Photorealistic rendering of knitwear using the lumislice. In Proceedings of the 28th Annual Conference on Computer Graphics and Interactive Techniques, ACM, 391–398. Google ScholarDigital Library

19. Yuksel, C., Kaldor, J. M., James, D. L., and Marschner, S. 2012. Stitch meshes for modeling knitted clothing with yarn-level detail. ACM Trans. Graph. 31, 3, 37:1–37:12. Google ScholarDigital Library

20. Zhao, S., Jakob, W., Marschner, S., and Bala, K. 2011. Building volumetric appearance models of fabric using micro CT imaging. ACM Trans. Graph. 30, 4, 44:1–44:10. Google ScholarDigital Library

21. Zhao, S., Jakob, W., Marschner, S., and Bala, K. 2012. Structure-aware synthesis for predictive woven fabric appearance. ACM Trans. Graph. 31, 4, 75:1–75:10. Google ScholarDigital Library

22. Zhao, S., Hašan, M., Ramamoorthi, R., and Bala, K. 2013. Modular flux transfer: Efficient rendering of high-resolution volumes with repeated structures. ACM Trans. Graph. 32, 4, 131:1–131:12. Google ScholarDigital Library