“Microstructures to control elasticity in 3D printing” by Schumacher, Bickel, Rys, Marschner, Daraio, et al. …

Conference:

Type(s):

Title:

- Microstructures to control elasticity in 3D printing

Presenter(s)/Author(s):

Abstract:

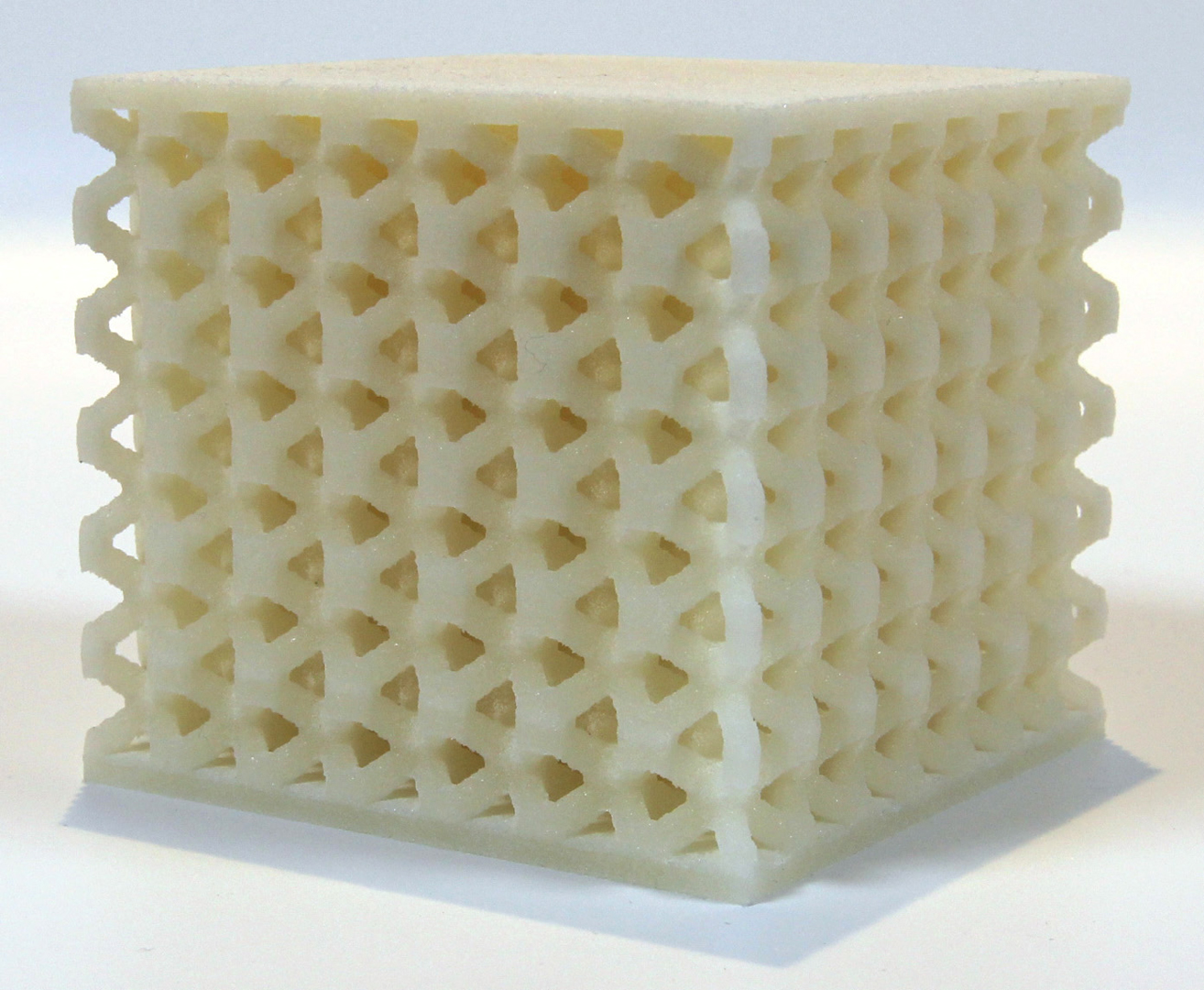

We propose a method for fabricating deformable objects with spatially varying elasticity using 3D printing. Using a single, relatively stiff printer material, our method designs an assembly of small-scale microstructures that have the effect of a softer material at the object scale, with properties depending on the microstructure used in each part of the object. We build on work in the area of metamaterials, using numerical optimization to design tiled microstructures with desired properties, but with the key difference that our method designs families of related structures that can be interpolated to smoothly vary the material properties over a wide range. To create an object with spatially varying elastic properties, we tile the object’s interior with microstructures drawn from these families, generating a different microstructure for each cell using an efficient algorithm to select compatible structures for neighboring cells. We show results computed for both 2D and 3D objects, validating several 2D and 3D printed structures using standard material tests as well as demonstrating various example applications.

References:

1. Attard, D., and Grima, J. N. 2012. A three-dimensional rotating rigid units network exhibiting negative poisson’s ratios. physica status solidi (b) 249, 7, 1330–1338.Google Scholar

2. Babaee, S., Shim, J., Weaver, J. C., Patel, N., and Bertoldi, K. 2013. 3d soft metamaterials with negative poisson’s ratio. Advanced Materials 25, 5044–5049.Google ScholarCross Ref

3. Becker, M., and Teschner, M. 2007. Robust and efficient estimation of elasticity parameters using the linear finite element method. In Proceedings of the Conference on Simulation and Visualization (SimVis), 15–28.Google Scholar

4. Bickel, B., Bächer, M., Otaduy, M. A., Lee, H. R., Pfister, H., Gross, M., and Matusik, W. 2010. Design and fabrication of materials with desired deformation behavior. ACM Trans. Graph. (Proc. SIGGRAPH) 29, 3. Google ScholarDigital Library

5. Byrd, R. H., Lu, P., Nocedal, J., and Zhu, C. 1995. A limited memory algorithm for bound constrained optimization. SIAM J. Sci. Comput. 16, 1190–1208. Google ScholarDigital Library

6. Chen, D., Levin, D. I. W., Didyk, P., Sitthi-Amorn, P., and Matusik, W. 2013. Spec2Fab: A reducer-tuner model for translating specifications to 3D prints. ACM Trans. Graph. (Proc. SIGGRAPH) 32, 4. Google ScholarDigital Library

7. Cioranescu, D., and Donato, P. 2000. Introduction to homogenization.Google Scholar

8. Coelho, P., Fernandes, P., Guedes, J., and Rodrigues, H. 2008. A hierarchical model for concurrent material and topology optimisation of three-dimensional structures. Structural and Multidisciplinary Optimization 35, 2, 107–115.Google ScholarCross Ref

9. Derbinsky, N., Bento, J., Elser, V., and Yedidia, J. S. 2013. An improved three-weight message-passing algorithm. arXiv:1305.1961.Google Scholar

10. Dong, Y., Wang, J., Pellacini, F., Tong, X., and Guo, B. 2010. Fabricating spatially-varying subsurface scattering. ACM Trans. Graph. (Proc. SIGGRAPH) 29, 4. Google ScholarDigital Library

11. Hašan, M., Fuchs, M., Matusik, W., Pfister, H., and Rusinkiewicz, S. 2010. Physical reproduction of materials with specified subsurface scattering. ACM Trans. Graph. (Proc. SIGGRAPH) 29, 4. Google ScholarDigital Library

12. Hashin, Z., and Shtrikman, S. 1963. A variational approach to the theory of the elastic behaviour of multiphase materials. Journal of the Mechanics and Physics of Solids 11, 2, 127–140.Google ScholarCross Ref

13. Hiller, J., and Lipson, H. 2012. Automatic design and manufacture of soft robots. Robotics, IEEE Transactions on 28, 2, 457–466. Google ScholarDigital Library

14. Huang, X., Radman, A., and Xie, Y. 2011. Topological design of microstructures of cellular materials for maximum bulk or shear modulus. Computational Materials Science 50, 6, 1861–1870.Google ScholarCross Ref

15. Hughes, T., Marmier, A., and Evans, K. 2010. Auxetic frameworks inspired by cubic crystals. International Journal of Solids and Structures 47, 11.Google ScholarCross Ref

16. Kharevych, L., Mullen, P., Owhadi, H., and Desbrun, M. 2009. Numerical coarsening of inhomogeneous elastic materials. ACM Trans. Graph. (Proc. SIGGRAPH) 28, 51. Google ScholarDigital Library

17. Lakes, R. 1987. Foam structures with a negative poisson’s ratio. Science 235, 4792, 1038–1040.Google Scholar

18. Lan, Y., Dong, Y., Pellacini, F., and Tong, X. 2013. Bi-scale appearance fabrication. ACM Trans. Graph. (Proc. SIGGRAPH) 32, 4. Google ScholarDigital Library

19. Lee, J.-H., Singer, J. P., and Thomas, E. L. 2012. Micro-/nanostructured mechanical metamaterials. Advanced Materials 24, 36, 4782–4810.Google ScholarCross Ref

20. Michel, J., Moulinec, H., and Suquet, P. 1999. Effective properties of composite materials with periodic microstructure: a computational approach. Computer methods in applied mechanics and engineering 172, 1, 109–143.Google Scholar

21. Nealen, A., Müller, M., Keiser, R., Boxerman, E., and Carlson, M. 2006. Physically based deformable models in computer graphics. Computer Graphics Forum 25, 4, 809–836.Google ScholarCross Ref

22. Nealen, A. 2004. An as-short-as-possible introduction to the least squares, weighted least squares and moving least squares methods for scattered data approximation and interpolation. Tech. rep., TU Darsmstadt.Google Scholar

23. Nesme, M., Kry, P. G., Jeřábková, L., and Faure, F. 2009. Preserving topology and elasticity for embedded deformable models. ACM Trans. Graph. (Proc. SIGGRAPH) 28, 3. Google ScholarDigital Library

24. Reiner, T., Carr, N., Mech, R., Stava, O., Dachsbacher, C., and Miller, G. 2014. Dual-color mixing for fused deposition modeling printers. Computer Graphics Forum (EUROGRAPHICS 2014 Proceedings) 33, 2. Google ScholarDigital Library

25. Rodrigues, H., Guedes, J., and Bendsoe, M. 2002. Hierarchical optimization of material and structure. Structural and Multidisciplinary Optimization 24, 1, 1–10.Google ScholarCross Ref

26. Rouiller, O., Bickel, B., Kautz, J., Matusik, W., and Alexa, M. 2013. 3d-printing spatially varying brdfs. Computer Graphics and Applications, IEEE 33, 6. Google ScholarDigital Library

27. Sifakis, E., and Barbic, J. 2012. Fem simulation of 3d deformable solids: a practitioner’s guide to theory, discretization and model reduction. In ACM SIGGRAPH 2012 Courses, 20. Google ScholarDigital Library

28. Sigmund, O., and Petersson, J. 1998. Numerical instabilities in topology optimization: a survey on procedures dealing with checkerboards, mesh-dependencies and local minima. Structural optimization 16, 1, 68–75.Google Scholar

29. Sigmund, O. 2009. Systematic design of metamaterials by topology optimization. In IUTAM Symposium on Modelling Nanomaterials and Nanosystems, Springer, 151–159.Google ScholarCross Ref

30. Skouras, M., Thomaszewski, B., Coros, S., Bickel, B., and Gross, M. 2013. Computational design of actuated deformable characters. ACM Trans. Graph. (Proc. SIGGRAPH) 32, 4. Google ScholarDigital Library

31. Smit, R., Brekelmans, W., and Meijer, H. 1998. Prediction of the mechanical behavior of nonlinear heterogeneous systems by multi-level finite element modeling. Computer Methods in Applied Mechanics and Engineering 155, 1, 181–192.Google ScholarCross Ref

32. Stava, O., Vanek, J., Benes, B., Carr, N., and Měch, R. 2012. Stress relief: improving structural strength of 3d printable objects. ACM Trans. Graph. (Proc. SIGGRAPH) 31, 4. Google ScholarDigital Library

33. Vidimče, K., Wang, S.-P., Ragan-Kelley, J., and Matusik, W. 2013. Openfab: A programmable pipeline for multimaterial fabrication. ACM Trans. Graph. (Proc. SIGGRAPH) 32. Google ScholarDigital Library

34. Wang, W., Wang, T. Y., Yang, Z., Liu, L., Tong, X., Tong, W., Deng, J., Chen, F., and Liu, X. 2013. Cost-effective printing of 3d objects with skin-frame structures. ACM Trans. Graph. (Proc. SIGGRAPH Asia) 32, 6. Google ScholarDigital Library

35. Weyrich, T., Peers, P., Matusik, W., and Rusinkiewicz, S. 2009. Fabricating microgeometry for custom surface reflectance. ACM Trans. Graph. (Proc. SIGGRAPH) 28, 3. Google ScholarDigital Library

36. Xu, H., Li, Y., Chen, Y., and Barbič, J. 2015. Interactive material design using model reduction. ACM Trans. Graph. (TOG) 34, 2. Google ScholarDigital Library

37. Zhou, S., and Li, Q. 2008. Design of graded two-phase microstructures for tailored elasticity gradients. Journal of Materials Science 43, 15, 5157–5167.Google ScholarCross Ref

38. Zhou, Q., Panetta, J., and Zorin, D. 2013. Worst-case structural analysis. ACM Trans. Graph. (Proc. SIGGRAPH) 32, 4. Google ScholarDigital Library