“A thermomechanical material point method for baking and cooking” by Ding, Han, Wang, Gast and Teran

Conference:

Type(s):

Title:

- A thermomechanical material point method for baking and cooking

Session/Category Title:

- Fluids Aflow

Presenter(s)/Author(s):

Moderator(s):

Abstract:

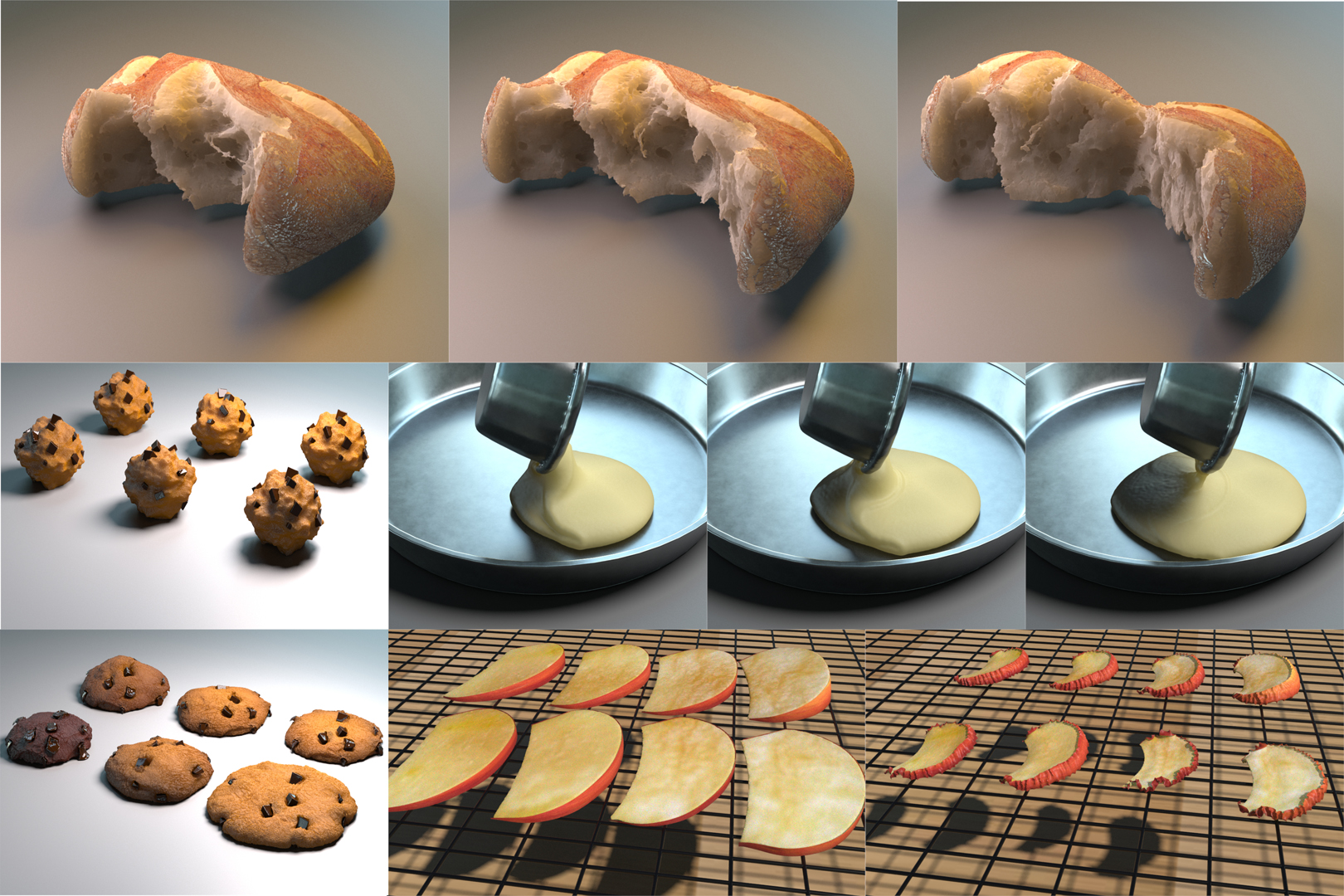

We present a Material Point Method for visual simulation of baking breads, cookies, pancakes and similar materials that consist of dough or batter (mixtures of water, flour, eggs, fat, sugar and leavening agents). We develop a novel thermomechanical model using mixture theory to resolve interactions between individual water, gas and dough species. Heat transfer with thermal expansion is used to model thermal variations in material properties. Water-based mass transfer is resolved through the porous mixture, gas represents carbon dioxide produced by leavening agents in the baking process and dough is modeled as a viscoelastoplastic solid to represent its varied and complex rheological properties. Water content in the mixture reduces during the baking process according to Fick’s Law which contributes to drying and cracking of crust at the material boundary. Carbon dioxide gas produced by leavening agents during baking creates internal pressure that causes rising. The viscoelastoplastic model for the dough is temperature dependent and is used to model melting and solidification. We discretize the governing equations using a novel Material Point Method designed to track the solid phase of the mixture.

References:

1. K. Abe, K. Soga, and S. Bandara. 2014. Material Point Method for Coupled Hydromechanical Problems. J Geotech Geoenv Eng 140, 3 (2014), 04013033.Google ScholarCross Ref

2. R. Atkin and R. Craine. 1976. Continuum theories of mixtures: basic theory and historical development. Quart J Mech App Math 29, 2 (1976), 209–244.Google ScholarCross Ref

3. S. Bandara, A. Ferrari, and L. Laloui. 2016. Modelling landslides in unsaturated slopes subjected to rainfall infiltration using material point method. Int J Num Anal Meth Geomech 40, 9 (2016), 1358–1380.Google ScholarCross Ref

4. S. Bandara and K. Soga. 2015. Coupling of soil deformation and pore fluid flow using material point method. Comp Geotech 63 (2015), 199–214.Google ScholarCross Ref

5. K. Bao, X. Wu, H. Zhang, and E. Wu. 2010. Volume fraction based miscible and immiscible fluid animation. Comp Anim Virtual Worlds 21, 3–4 (2010), 401–410.Google Scholar

6. A. Bargteil, C. Wojtan, J. Hodgins, and G. Turk. 2007. A finite element method for animating large viscoplastic flow. ACM Trans Graph 26, 3 (2007).Google ScholarDigital Library

7. H. Barreiro, I. García-Fernández, I. Alduán, and M.-A. Otaduy. 2017. Conformation constraints for efficient viscoelastic fluid simulation. ACM Transactions on Graphics (TOG) 36, 6 (2017), 221.Google ScholarDigital Library

8. M. Biot. 1941. General theory of three-dimensional consolidation. J App Phys 12, 2 (1941), 155–164.Google ScholarCross Ref

9. J. Blutinger, Y. Meijers, P. Chen, C. Zheng, E. Grinspun, and H. Lipson. 2019. Characterization of CO2 laser browning of dough. Innovative Food Science & Emerging Technologies 52 (2019), 145–157.Google ScholarCross Ref

10. J. Bonet and R. Wood. 2008. Nonlinear continuum mechanics for finite element analysis. Cambridge University Press.Google Scholar

11. J. Brackbill and H. Ruppel. 1986. FLIP: A method for adaptively zoned, Particle-In-Cell calculations of fluid flows in two dimensions. J Comp Phys 65 (1986), 314–343.Google ScholarDigital Library

12. B. Broyart and G. Trystram. 2002. Modelling heat and mass transfer during the continuous baking of biscuits. Journal of Food Engineering 51, 1 (2002), 47–57.Google ScholarCross Ref

13. M. Carlson, P. J. Mucha, R. B. Van Horn III, and G. Turk. 2002. Melting and flowing. In Proceedings of the 2002 ACM SIGGRAPH/Eurographics symposium on Computer animation. ACM, 167–174.Google Scholar

14. P. Chen, J. Blutinger, Y. Meijersand C. Zheng, E. Grinspun, and H. Lipson. 2019. Visual modeling of laser-induced dough browning. Journal of Food Engineering 243 (2019), 9–21.Google ScholarCross Ref

15. B. De Cindio and S. Correra. 1995. Mathematical modelling of leavened cereal goods. Journal of Food Engineering 24, 3 (1995), 379–403.Google ScholarCross Ref

16. G. Daviet and F. Bertails-Descoubes. 2016. A Semi-implicit Material Point Method for the Continuum Simulation of Granular Materials. ACM Trans Graph 35, 4 (2016), 102:1–102:13.Google ScholarDigital Library

17. F. Debaste, A. Léonard, V. Halloin, and B. Haut. 2010. Microtomographic investigation of a yeast grain porous structure. Journal of Food Engineering 97, 4 (April 2010), 526–532. Google ScholarCross Ref

18. M. Ding, X. Han, S. Wang, T. Gast, and J. Teran. 2019. Supplementary Technical Document. Technical Report.Google Scholar

19. H. Faridi and J. Faubion. 2012. Dough rheology and baked product texture. Springer Science & Business Media.Google Scholar

20. Y. Fei, C. Batty, E. Grinspun, and C. Zheng. 2018. A multi-scale model for simulating liquid-fabric interactions. ACM Trans Graph 37, 4 (2018), 51:1–51:16. Google ScholarDigital Library

21. A. Fick. 1855. On liquid diffusion. London, Edinburgh, and Dublin Philos Mag J Sci 10 (1855), 30–39.Google ScholarCross Ref

22. M. Gao, A. Pradhana, X. Han, Q. Guo, G. Kot, E. Sifakis, and C. Jiang. 2018a. Animating fluid sediment mixture in particle-laden flows. ACM Trans Graph 37, 4 (2018), 149:1–149:11. Google ScholarDigital Library

23. M. Gao, X. Wang, Kui K. Wu, A. Pradhana, E. Sifakis, C. Yuksel, and C. Jiang. 2018b. GPU optimization of material point methods. In SIGGRAPH Asia 2018 Technical Papers (SIGGRAPH Asia ’18). ACM, New York, NY, USA, Article 254, 12 pages. Google ScholarDigital Library

24. J. Gaume, T. Gast, J. Teran, A. van Herwijnen, and C. Jiang. 2018. Dynamic anticrack propagation in snow. Nature Com 9, 1 (2018), 3047.Google ScholarCross Ref

25. D. Gerszewski, H. Bhattacharya, and A. Bargteil. 2009. A point-based method for animating elastoplastic solids. In Proc 2009 ACM SIGGRAPH/Eurograph Symp Comp Anim. ACM, 133–138. Google ScholarDigital Library

26. T. Goktekin, A. Bargteil, and J. O’Brien. 2004. A Method for Animating Viscoelastic Fluids. ACM Trans Graph 23, 3 (2004), 463–468.Google ScholarDigital Library

27. O. Gonzalez and A. Stuart. 2008. A first course in continuum mechanics. Cambridge University Press.Google Scholar

28. V. Guillard, B. Broyart, S. Guilbert, C. Bonazzi, and N. Gontard. 2004. Moisture diffusivity and transfer modelling in dry biscuit. Journal of Food Engineering 64, 1 (2004), 81–87.Google ScholarCross Ref

29. Q. Guo, X. Han, C. Fu, T. Gast, R. Tamstorf, and J. Teran. 2018. A material point method for thin shells with frictional contact. ACM Trans Graph 37, 4 (2018), 147. Google ScholarDigital Library

30. M. Haghi and L. Anand. 1992. A constitutive model for isotropic, porous, elasticviscoplastic metals. Mechanics of Materials 13, 1 (March 1992), 37–53. Google ScholarCross Ref

31. F. Harlow. 1964. The particle-in-cell method for numerical solution of problems in fluid dynamics. Meth Comp Phys 3 (1964), 319–343.Google Scholar

32. X. He, H. Wang, F. Zhang, H. Wang, G. Wang, K. Zhou, and E. Wu. 2015. Simulation of Fluid Mixing with Interface Control. In Proc ACM SIGGRAPH / Eurograph Symp Comp Anim. ACM, 129–135.Google Scholar

33. Y. Hu, Q. Zhou, X. Gao, A. Jacobson, D. Zorin, and D. Panozzo. 2018. Tetrahedral Meshing in the Wild. ACM Trans. Graph. 37, 4, Article 60 (July 2018), 14 pages. Google ScholarDigital Library

34. I. Jassim, D. Stolle, and P. Vermeer. 2013. Two-phase dynamic analysis by material point method. Int J Num Anal Meth Geomech 37, 15 (2013), 2502–2522. Google ScholarCross Ref

35. C. Jiang, T. Gast, and J. Teran. 2017a. Anisotropic elastoplasticity for cloth, knit and hair frictional contact. ACM Trans Graph 36, 4 (2017), 152.Google ScholarDigital Library

36. C. Jiang, C. Schroeder, A. Selle, J. Teran, and A. Stomakhin. 2015. The Affine Particle-In-Cell Method. ACM Trans Graph 34, 4 (2015), 51:1–51:10.Google ScholarDigital Library

37. C. Jiang, C. Schroeder, and J. Teran. 2017b. An angular momentum conserving affine-particle-in-cell method. J Comp Phys 338 (2017), 137 — 164.Google ScholarDigital Library

38. N. Kang, J. Park, J. Noh, and S. Shin. 2010. A Hybrid Approach to Multiple Fluid Simulation using Volume Fractions. Comp Graph Forum 29, 2 (2010), 685–694.Google ScholarCross Ref

39. R. Keiser, B. Adams, D. Gasser, P. Bazzi, P. Dutré, and M. Gross. 2005. A unified lagrangian approach to solid-fluid animation. In Proceedings Eurographics/IEEE VGTC Symposium Point-Based Graphics, 2005. IEEE, 125–148.Google ScholarCross Ref

40. G. Klár, T. Gast, A. Pradhana, C. Fu, C. Schroeder, C. Jiang, and J. Teran. 2016. Drucker-prager Elastoplasticity for Sand Animation. ACM Trans Graph 35, 4 (2016), 103:1–103:12.Google ScholarDigital Library

41. S. Liu, Z. Wang, Z. Gong, and Q. Peng. 2008. Simulation of Atmospheric Binary Mixtures Based on Two-fluid Model. Graph Mod 70, 6 (2008), 117–124.Google ScholarDigital Library

42. Y. Liu, X. Yang, Y. Cao, Z. Wang, B. Chen, J. Zhang, and H. Zhang. 2015. Dehydration of core/shell fruits. Computers & Graphics 47 (April 2015), 68–77. Google ScholarDigital Library

43. F. Losasso, G. Irving, E. Guendelman, and R. Fedkiw. 2006. Melting and burning solids into liquids and gases. IEEE Transactions on Visualization and Computer Graphics 12, 3 (2006), 343–352.Google ScholarDigital Library

44. F. Losasso, J. Talton, N. Kwatra, and R. Fedkiw. 2008. Two-Way Coupled SPH and Particle Level Set Fluid Simulation. IEEE Trans Visu Comp Graph 14, 4 (2008), 797–804.Google ScholarDigital Library

45. N. Maréchal, E. Guérin, E. Galin, S. Mérillou, and N. Mérillou. 2010. Heat transfer simulation for modeling realistic winter sceneries. In Computer Graphics Forum, Vol. 29. Wiley Online Library, 449–458.Google Scholar

46. V. Mihalef, D. Metaxas, and M. Sussman. 2009. Simulation of two-phase flow with sub-scale droplet and bubble effects. Comp GraphForum 28, 2 (2009), 229–238.Google Scholar

47. M. Müller, B. Heidelberger, M. Teschner, and M. Gross. 2005. Meshless deformations based on shape matching. In ACM transactions on graphics (TOG), Vol. 24. ACM, 471–478.Google Scholar

48. M. Müller, R. Keiser, A. Nealen, M. Pauly, M. Gross, and M. Alexa. 2004. Point based animation of elastic, plastic and melting objects. In Proc ACM SIGGRAPH/Eurograp Symp Comp Anim. 141–151. Google ScholarDigital Library

49. V. Nicolas, P. Salagnac, P. Glouannec, J.-P. Ploteau, V. Jury, and L. Boillereaux. 2014. Modelling heat and mass transfer in deformable porous media: Application to bread baking. Journal of Food Engineering 130 (June 2014), 23–35. Google ScholarCross Ref

50. M. Nielsen and O. Osterby. 2013. A Two-continua Approach to Eulerian Simulation of Water Spray. ACM Trans Graph 32, 4 (2013), 67:1–67:10.Google ScholarDigital Library

51. D. Ram, T. Gast, C. Jiang, C. Schroeder, A. Stomakhin, J. Teran, and P. Kavehpour. 2015. A material point method for viscoelastic fluids, foams and sponges. In Proc ACM SIGGRAPH/Eurograph Symp Comp Anim. 157–163.Google Scholar

52. B. Ren, Y. Jiang, C. Li, and M. Lin. 2015. A simple approach for bubble modelling from multiphase fluid simulation. Comp Vis Media 1, 2 (2015), 171–181.Google ScholarCross Ref

53. B. Ren, C. Li, X. Yan, M. Lin, J. Bonet, and S. Hu. 2014. Multiple-Fluid SPH Simulation Using a Mixture Model. ACM Trans Graph 33, 5 (2014), 171:1–171:11.Google ScholarDigital Library

54. K. Roscoe and J. Burland. 1968. On the generalized stress-strain behaviour of wet clay. Eng Plast (1968), 535–609.Google Scholar

55. M. Sakin-Yilmazer, T. Kemerli, H. Isleroglu, O. Ozdestan, G. Guven, A. Uren, and F. Kaymak-Ertekin. 2013. Porous media based model for deep-fat vacuum frying potato chips. Journal of Food Engineering 110, 3 (Dec. 2013), 483–489. Google ScholarCross Ref

56. A. Shah. 2007. Anyone Can Cook-Inside Ratatouille’s Kitchen. SIGGRAPH 2007 Course Notes 30 (2007), 58.Google Scholar

57. J. Simo and G. Meschke. 1993. A new class of algorithms for classical plasticity extended to finite strains. Application to geomaterials. Comput Mech 11, 4 (1993), 253–278.Google ScholarCross Ref

58. A. Stomakhin, C. Schroeder, L. Chai, J. Teran, and A. Selle. 2013. A Material Point Method for snow simulation. ACM Trans Graph 32, 4 (2013), 102:1–102:10.Google ScholarDigital Library

59. A. Stomakhin, C. Schroeder, C. Jiang, L. Chai, J. Teran, and A. Selle. 2014. Augmented MPM for phase-change and varied materials. ACM Trans Graph 33, 4 (2014), 138:1–138:11.Google ScholarDigital Library

60. D. Sulsky, Z. Chen, and H. Schreyer. 1994. A particle method for history-dependent materials. Comp Meth App Mech Eng 118, 1 (1994), 179–196.Google ScholarCross Ref

61. T. Takahashi, H. Fujii, A. Kunimatsu, K. Hiwada, T. Saito, K. Tanaka, and H. Ueki. 2003. Realistic Animation of Fluid with Splash and Foam. Comp Graph Forum 22, 3 (2003), 391–400.Google ScholarCross Ref

62. A. P. Tampubolon, T. Gast, G. Klár, C. Fu, J. Teran, C. Jiang, and K. Museth. 2017. Multi-species simulation of porous sand and water mixtures. ACM Trans Graph 36, 4 (2017).Google ScholarDigital Library

63. D. Terzopoulosi, J. Platt, and K. Fleischer. 1991. Heating and melting deformable models. The Journal of Visualization and Computer Animation 2, 2 (1991), 68–73.Google ScholarCross Ref

64. M. Teschner, B. Heidelberger, M. Muller, and M. Gross. 2004. A versatile and robust model for geometrically complex deformable solids. In Proceedings Computer Graphics International, 2004. IEEE, 312–319.Google Scholar

65. K. Thorvaldsson and C. Skjöldebrand. 1998. Water diffusion in bread during baking. LWT-Food Science and Technology 31, 7–8 (1998), 658–663.Google ScholarCross Ref

66. N. Thürey, F. Sadlo, S. Schirm, M. Müller-Fischer, and M. Gross. 2007. Real-time Simulations of Bubbles and Foam Within a Shallow Water Framework. In Proc ACM SIGGRAPH/Eurograph Symp Comp Anim. Eurographics Association, 191–198.Google Scholar

67. F. Vanin, T. Lucas, and G. Trystram. 2009. Crust formation and its role during bread baking. Trends in Food Science & Technology 20, 8 (2009), 333–343.Google ScholarCross Ref

68. S. Wang, M. Ding, T. Gast, L. Zhu, S. Gagniere, C. Jiang, and J. Teran. 2019. Simulation and Visualization of Ductile Fracture with the Material Point Method. Proceedings of the ACM on Computer Graphics and Interactive Techniques 2, 2, 18.Google ScholarDigital Library

69. X. Wei, W. Li, and A. Kaufman. 2003. Melting and Flowing of Viscous Volumes. In Proceedings of the 16th International Conference on Computer Animation and Social Agents (CASA 2003). IEEE Computer Society, 54.Google Scholar

70. M. Wicke, D. Ritchie, B. Klingner, S. Burke, J. Shewchuk, and J. O’Brien. 2010. Dynamic local remeshing for elastoplastic simulation. ACM Trans Graph 29, 4 (2010), 49:1–11.Google ScholarDigital Library

71. C. Wojtan and G. Turk. 2008. Fast viscoelastic behavior with thin features. ACM Trans Graph 27, 3 (2008), 1–8. Google ScholarDigital Library

72. L. Yang, S. Li, A. Hao, and H. Qin. 2014. Hybrid Particle-grid Modeling for Multi-scale Droplet/Spray Simulation. Comp Graph Forum 33, 7 (2014), 199–208.Google ScholarDigital Library

73. T. Yang, J. Chang, M. C. Lin, R. R. Martin, J. J. Zhang, and S.-M. Hu. 2017. A unified particle system framework for multi-phase, multi-material visual simulations. ACM Transactions on Graphics (TOG) 36, 6 (2017), 224.Google ScholarDigital Library

74. T. Yang, J. Chang, B. Ren, M. Lin, J. Zhang, and S. Hu. 2015. Fast Multiple-fluid Simulation Using Helmholtz Free Energy. ACM Trans Graph 34, 6 (2015), 201:1–201:11.Google ScholarDigital Library

75. A. Yerro, E. Alonso, and N. Pinyol. 2015. The material point method for unsaturated soils. Geotechnique 65, 3 (2015), 201–217.Google ScholarCross Ref

76. Y. Yue, B. Smith, C. Batty, C. Zheng, and E. Grinspun. 2015. Continuum foam: a material point method for shear-dependent flows. ACM Trans Graph 34, 5 (2015), 160:1–160:20.Google ScholarDigital Library

77. Y. Yue, B. Smith, P. Chen, M. Chantharayukhonthorn, K. Kamrin, and E. Grinspun. 2018. Hybrid grains: adaptive coupling of discrete and continuum simulations of granular media. ACM Trans Graph 37, 6 (2018), 283:1–283:19.Google ScholarDigital Library

78. H. Zhang, K. Wang, and Z. Chen. 2009. Material point method for dynamic analysis of saturated porous media under external contact/impact of solid bodies. Comp Meth App Mech Eng 198, 17 (2009), 1456–1472. Google ScholarCross Ref

79. J. Zhang and A. Datta. 2006. Mathematical modeling of bread baking process. Journal of Food Engineering 75, 1 (July 2006), 78–89. Google ScholarCross Ref

80. Q. Zhao and P. Papadopoulos. 2013. Modeling and simulation of liquid diffusion through a porous finitely elastic solid. Computational Mechanics 52, 3 (Sept. 2013), 553–562. Google ScholarDigital Library

81. Y. Zhao, L. Wang, F. Qiu, A. Kaufman, and K. Mueller. 2006. Melting and flowing in multiphase environment. Computers & Graphics 30, 4 (2006), 519–528.Google ScholarCross Ref