“Perceptual models of preference in 3D printing direction”

Conference:

Type(s):

Title:

- Perceptual models of preference in 3D printing direction

Session/Category Title: Fabrication

Presenter(s)/Author(s):

Abstract:

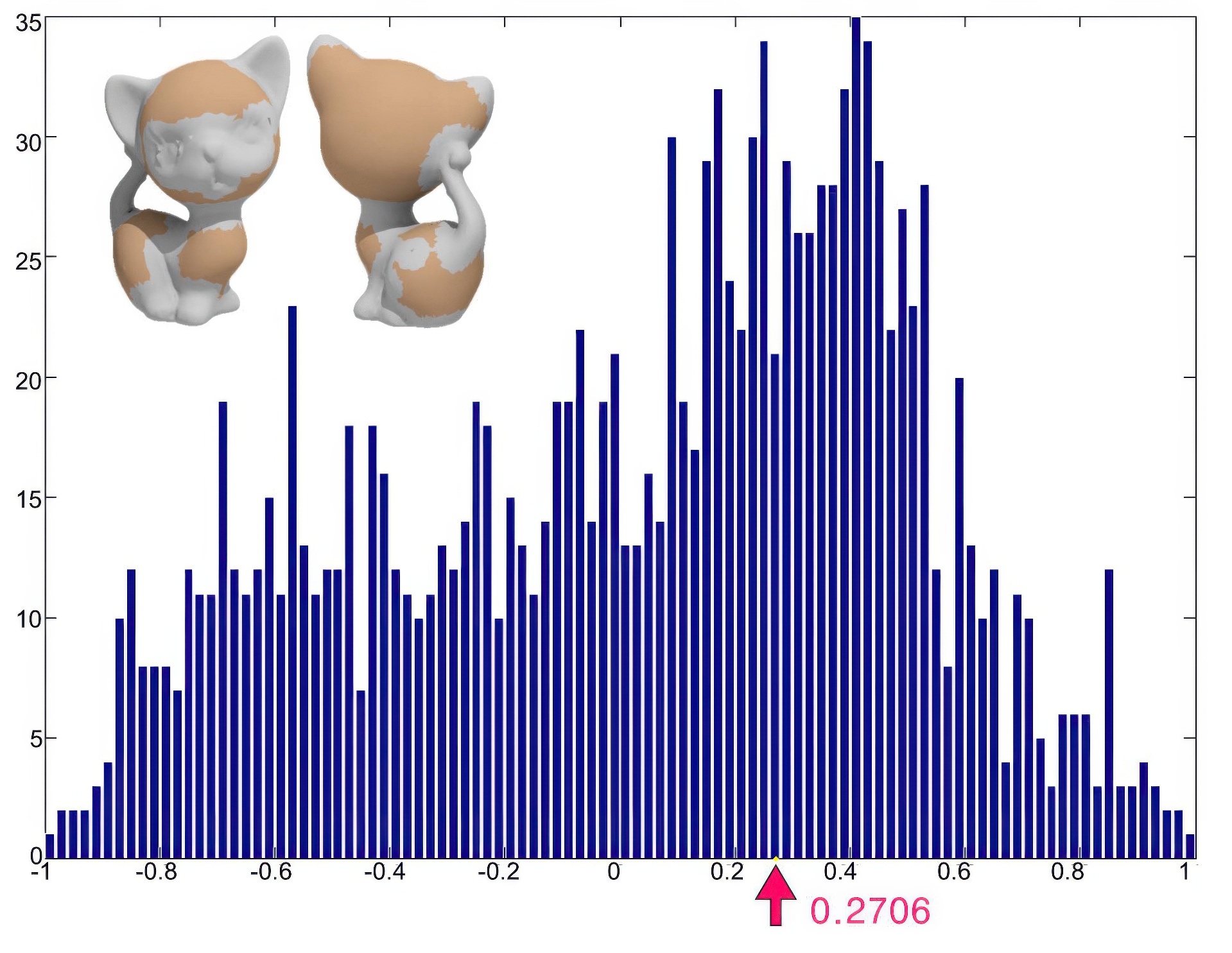

This paper introduces a perceptual model for determining 3D printing orientations. Additive manufacturing methods involving low-cost 3D printers often require robust branching support structures to prevent material collapse at overhangs. Although the designed shape can successfully be made by adding supports, residual material remains at the contact points after the supports have been removed, resulting in unsightly surface artifacts. Moreover, fine surface details on the fabricated model can easily be damaged while removing supports. To prevent the visual impact of these artifacts, we present a method to find printing directions that avoid placing supports in perceptually significant regions. Our model for preference in 3D printing direction is formulated as a combination of metrics including area of support, visual saliency, preferred viewpoint and smoothness preservation. We develop a training-and-learning methodology to obtain a closed-form solution for our perceptual model and perform a large-scale study. We demonstrate the performance of this perceptual model on both natural and man-made objects.

References:

1. Alexander, P., Allen, S., and Dutta, D. 1998. Part orientation and build cost determination in layered manufacturing. Computer-Aided Design 2, 3, 343–356.

2. Chalasani, K., Jones, L., and Roscoe, L. 1995. Support generation for fused deposition modeling. In Proceedings of 1995 Symposium on Solid Freeform Fabrication, 229–241.

3. Chen, Y., Li, K., and Qian, X. 2013. Direct geometry processing for tele-fabrication. ASME Journal of Computing and Information Science in Engineering 13, 4, 041002.

4. Cheng, W., Fuh, J., Nee, A., Wong, Y., Loh, H., and Miyazawa, T. 1995. Multi-objective optimization of part-building orientation in stereolithography. Rapid Prototyping Journal 1, 4, 12–23.

5. Chorowski, J., Wang, J., and Zurada, J. M. 2014. Review and performance comparison of svm-and elm-based classifiers. Neurocomputing 128, 507–516.

6. Cochocki, A., and Unbehauen, R. 1993. Neural Networks for Optimization and Signal Processing. John Wiley & Sons, Inc.

7. Dong, Y., Wang, J., Pellacini, F., Tong, X., and Guo, B. 2010. Fabricating spatially-varying subsurface scattering. ACM Trans. Graph. 29, 4, 62:1–62:10.

8. Dumas, J., Hergel, J., and Lefebvre, S. 2014. Bridging the gap: Automated steady scaffoldings for 3d printing. ACM Trans. Graph. 33, 4 (July), 98:1–98:10.

9. Faure, F., Barbier, S., Allard, J., and Falipou, F. 2008. Image-based collision detection and response between arbitrary volume objects. In Proceedings of the 2008 ACM SIGGRAPH/Eurographics Symposium on Computer Animation, Eurographics Association, Aire-la-Ville, Switzerland, Switzerland, SCA ’08, 155–162.

10. Hearst, M., Dumais, S., Osman, E., Platt, J., and Scholkopf, B. 1998. Support vector machines. IEEE Intelligent Systems and their Applications 13, 4, 18–28.

11. Herholz, P., Matusik, W., and Alexa, M. 2015. Approximating free-form geometry with height fields for manufacturing. Computer Graphics Forum (Proc. of Eurographics) 34, 2, 239–251.

12. Hildebrand, K., Bickel, B., and Alexa, M. 2013. Orthogonal slicing for additive manufacturing. Computers & Graphics 37, 6, 669–675.

13. Hu, R., Li, H., Zhang, H., and Cohen-Or, D. 2014. Approximate pyramidal shape decomposition. ACM Transactions on Graphics (Proc. of SIGGRAPH Asia 2014) 33, 6, 213:1–213:12.

14. Hu, K., Jin, S., and Wang, C. 2015. Support slimming for single material based additive manufacturing. Computer-Aided Design 65, 1–10.

15. Huang, G.-B., Chen, L., and Siew, C.-K. 2006. Universal approximation using incremental constructive feedforward networks with random hidden nodes. Neural Networks, IEEE Transactions on 17, 4, 879–892.

16. Huang, G.-B., Zhu, Q.-Y., and Siew, C.-K. 2006. Extreme learning machine: theory and applications. Neurocomputing 70, 1, 489–501.

17. Huang, G.-B., Ding, X., and Zhou, H. 2010. Optimization method based extreme learning machine for classification. Neurocomputing 74, 1, 155–163.

18. Huang, G.-B., Wang, D. H., and Lan, Y. 2011. Extreme learning machines: a survey. International Journal of Machine Learning and Cybernetics 2, 2, 107–122.

19. Huang, G.-B., Zhou, H., Ding, X., and Zhang, R. 2012. Extreme learning machine for regression and multiclass classification. Systems, Man, and Cybernetics, Part B: Cybernetics, IEEE Transactions on 42, 2, 513–529.

20. Huang, G., Huang, G.-B., Song, S., and You, K. 2015. Trends in extreme learning machines: A review. Neural Networks 61, 32–48.

21. Kulkarni, P., Marsan, A., and Dutta, D. 2000. A review of process planning techniques in layered manufacturing. Rapid Prototyping Journal 6, 1, 18–35.

22. Lan, P.-T., Chou, S.-Y., Chen, L.-L., and Gemmill, D. 1997. Determining fabrication orientations for rapid prototyping with stereolithography apparatus. Computer-Aided Design 29, 1, 53–62.

23. Lan, Y., Dong, Y., Pellacini, F., and Tong, X. 2013. Bi-scale appearance fabrication. ACM Trans. Graph. 32, 4, 145:1–145:12.

24. Lee, C. H., Varshney, A., and Jacobs, D. W. 2005. Mesh saliency. ACM Trans. Graph. 24, 3 (July), 659–666.

25. Leung, Y.-S., and Wang, C. 2013. Conservative sampling of solids in image space. IEEE Comput. Graph. Appl. 33, 1 (Jan.), 32–43.

26. Levya, G. N., Schindela, R., and Kruth, J. P. 2003. Rapid manufacturing and rapid tooling with layer manufacturing {(LM)} technologies, state of the art and future perspectives. {CIRP} Annals – Manufacturing Technology 52, 2, 589–609.

27. Liu, L., Shamir, A., Wang, C., and Whiting, E. 2014. 3d printing oriented design: Geometry and optimization. In SIGGRAPH Asia 2014 Courses, ACM, New York, NY, USA, SA ’14.

28. Luo, L., Baran, I., Rusinkiewicz, S., and Matusik, W. 2012. Chopper: Partitioning models into 3D-printable parts. ACM Transactions on Graphics (Proc. SIGGRAPH Asia) 31, 6 (Dec.).

29. Majhi, J., Janardan, R., Smid, M., and Schwerdt, J. 1998. Multi-criteria geometric optimization problems in layered manufacturing. In Proceedings of the fourteenth annual symposium on Computational geometry, ACM, 19–28.

30. Masood, S., and Rattanawong, W. 2002. A generic part orientation system based on volumetric error in rapid prototyping. The International Journal of Advanced Manufacturing Technology 19, 3, 209–216.

31. Otsu, N. 1979. A threshold selection method from gray-level histograms. IEEE Transactions on Systems, Man and Cybernetics 9, 1, 62–66.

32. Padhye, N., and Deb, K. 2011. Multi-objective optimisation and multi-criteria decision making in SLS using evolutionary approaches. Rapid Prototyping Journal 17, 6, 458–478.

33. Papas, M., Regg, C., Jarosz, W., Bickel, B., Jackson, P., Matusik, W., Marschner, S., and Gross, M. 2013. Fabricating translucent materials using continuous pigment mixtures. ACM Trans. Graph. 32, 4, 146:1–146:12.

34. Podolak, J., Shilane, P., Golovinskiy, A., Rusinkiewicz, S., and Funkhouser, T. 2006. A planar-reflective symmetry transform for 3d shapes. ACM Trans. Graph. 25, 3, 549–559.

35. Rhodes, G., Proffitt, F., Grady, J. M., and Sumich, A. 1998. Facial symmetry and the perception of beauty. Psychonomic Bulletin and Review 5, 4, 659–669.

36. Sachs, E., Cima, M., Williams, P., Brancazio, D., and Cornie, J. 1992. Three dimensional printing: Rapid tooling and prototypes directly from a CAD model. ASME Journal of Engineering for Industry 114, 4, 481–488.

37. Schüller, C., Panozzo, D., and Sorkine-Hornung, O. 2014. Appearance-mimicking surfaces. ACM Trans. Graph. 33, 6, 216:1–216:10.

38. Secord, A., Lu, J., Finkelstein, A., Singh, M., and Nealen, A. 2011. Perceptual models of viewpoint preference. ACM Trans. Graph. 30, 5 (Oct.), 109:1–109:12.

39. Strano, G., Hao, L., Everson, R., and Evans, K. 2013. A new approach to the design and optimisation of support structures in additive manufacturing. The International Journal of Advanced Manufacturing Technology 66, 9–12, 1247–1254.

40. Umetani, N., and Schmidt, R. 2013. Cross-sectional structural analysis for 3d printing optimization. In SIGGRAPH Asia 2013 Technical Briefs, 5:1–5:4.

41. Vanek, J., Galicia, J. A. G., and Benes, B. 2014. Clever support: Efficient support structure generation for digital fabrication. Computer Graphics Forum 33, 5, 117–125.

42. Vidimče, K., Wang, S.-P., Ragan-Kelley, J., and Matusik, W. 2013. Openfab: A programmable pipeline for multi-material fabrication. ACM Trans. Graph. 32, 4, 136:1–136:12.

43. Wang, C. C. L., Leung, Y.-S., and Chen, Y. 2010. Solid modeling of polyhedral objects by layered depth-normal images on the gpu. Comput. Aided Des. 42, 6 (June), 535–544.

44. Wang, W., Wang, T. Y., Yang, Z., Liu, L., Tong, X., Tong, W., Deng, J., Chen, F., and Liu, X. 2013. Cost-effective printing of 3d objects with skin-frame structures. ACM Trans. Graph. 32, 6 (Nov.), 177:1–177:10.

45. Wang, W., Chao, H., Tong, J., Yang, Z., Tong, X., Li, H., Liu, X., and Liu, L. 2015. Saliency-preserving slicing optimization for effective 3d printing. Computer Graphics Forum.

46. Xie, Z., Xu, K., Liu, L., and Xiong, Y. 2014. 3d shape segmentation and labeling via extreme learning machine. Computer Graphics Forum 33, 5, 85–95.

47. Xie, Z., Xu, K., Shan, W., Liu, L., Xiong, Y., and Huang, H. 2015. Projective feature learning for 3d shapes with multi-view depth images. Computer Graphics Forum (Proc. of Pacific Graphics 2015) 34, 6, to appear.