“Architecture-scale human-assisted additive manufacturing” by Yoshida, Takami, Igarashi, Obit, Sato, et al. …

Conference:

Type:

Title:

- Architecture-scale human-assisted additive manufacturing

Session/Category Title: Fabricating Fabulous Forms

Presenter(s)/Author(s):

- Hironori Yoshida

- Yosuke Takami

- Takeo Igarashi

- Yusuke Obit

- Jun Sato

- Mika Araki

- Masaaki Miki

- Kosuke Nagata

- Kazuhide Sakai

- Syunsuke Igarashi

Moderator(s):

Abstract:

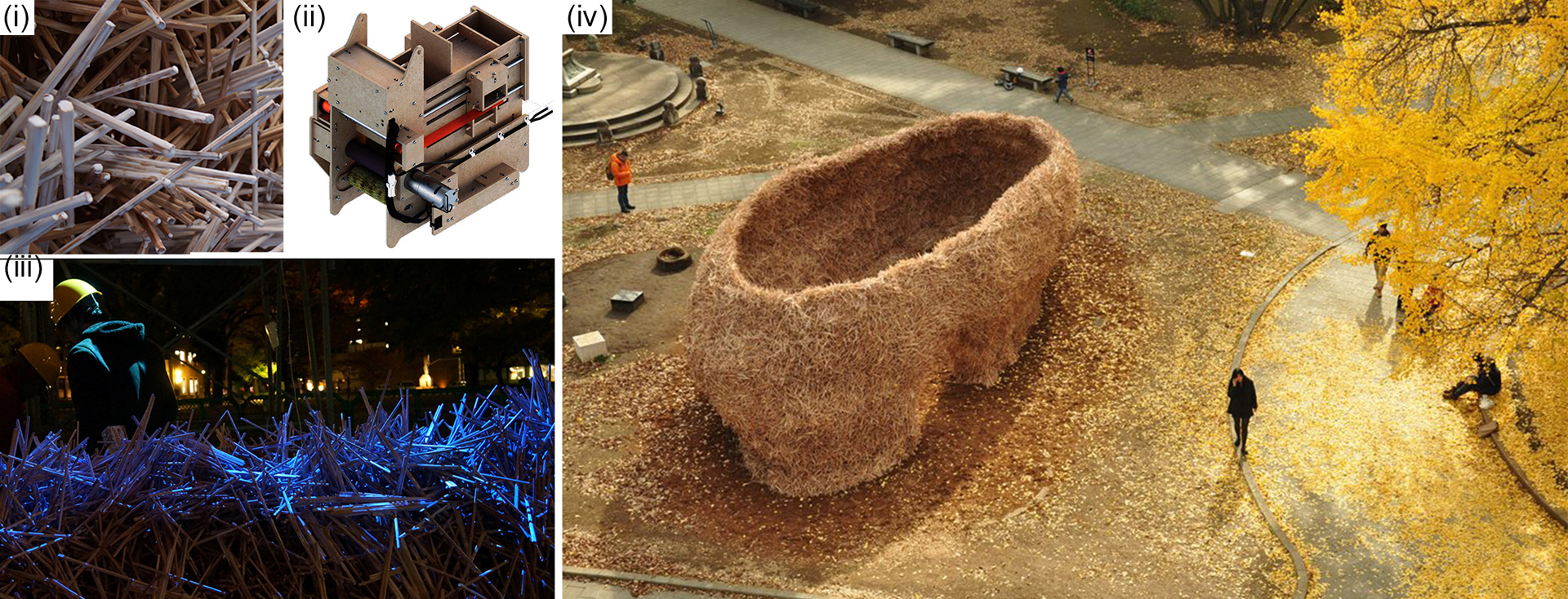

Recent digital fabrication tools have opened up accessibility to personalized rapid prototyping; however, such tools are limited to product-scale objects. The materials currently available for use in 3D printing are too fine for large-scale objects, and CNC gantry sizes limit the scope of printable objects. In this paper, we propose a new method for printing architecture-scale objects. Our proposal includes three developments: (i) a construction material consisting of chopsticks and glue, (ii) a handheld chopstick dispenser, and (iii) a printing guidance system that uses projection mapping. The proposed chopstickglue material is cost effective, environmentally sustainable, and can be printed more quickly than conventional materials. The developed handheld dispenser enables consistent feeding of the chopstickglue material composite. The printing guidance system — consisting of a depth camera and a projector — evaluates a given shape in real time and indicates where humans should deposit chopsticks by projecting a simple color code onto the form under construction. Given the mechanical specifications of the stickglue composite, an experimental pavilion was designed as a case study of the proposed method and built without scaffoldings and formworks. The case study also revealed several fundamental limitations, such as the projector does not work in daylight, which requires future investigations.

References:

1. Azuma, R. T., et al. 1997. A survey of augmented reality. Presence 6, 4, 355–385.Google ScholarDigital Library

2. Benko, H., Jota, R., and Wilson, A. 2012. Miragetable: freehand interaction on a projected augmented reality tabletop. In Proc. of CHI ’12, 199–208. Google ScholarDigital Library

3. Benko, H., Wilson, A. D., and Zannier, F. 2014. Dyadic projected spatial augmented reality. In Proc. of UIST ’14, 645–655. Google ScholarDigital Library

4. Bickel, B., Bächer, M., Otaduy, M. A., Matusik, W., Pfister, H., and Gross, M. 2009. Capture and modeling of non-linear heterogeneous soft tissue. 89.Google Scholar

5. Bickel, B., Bächer, M., Otaduy, M. A., Lee, H. R., Pfister, H., Gross, M., and Matusik, W. 2010. Design and fabrication of materials with desired deformation behavior. ACM Trans. Graph 29, 4, 63. Google ScholarDigital Library

6. Bock, T. 2007. Construction robotics. Autonomous Robots 22, 3, 201–209. Google ScholarDigital Library

7. Bogue, R. 2013. 3d printing: the dawn of a new era in manufacturing? Assembly Automation 33, 4, 307–311.Google ScholarDigital Library

8. Calì, J., Calian, D. A., Amati, C., Kleinberger, R., Steed, A., Kautz, J., and Weyrich, T. 2012. 3d-printing of non-assembly, articulated models. ACM Trans. Graph 31, 6, 130. Google ScholarDigital Library

9. Cesaretti, G., Dini, E., De Kestelier, X., Colla, V., and Pambaguian, L. 2014. Building components for an outpost on the lunar soil by means of a novel 3d printing technology. Acta Astronautica 93, 430–450.Google ScholarCross Ref

10. de Goes, F., Alliez, P., Owhadi, H., Desbrun, M., et al. 2013. On the equilibrium of simplicial masonry structures. ACM Trans. Graph 32, 4. Google ScholarDigital Library

11. Deuss, M., Panozzo, D., Whiting, E., Liu, Y., Block, P., Sokrine-Hornung, O., and Pauly, M. 2014. Assembling self-supporting structures. ACM Trans. Graph 33. Google ScholarDigital Library

12. Dierichs, K., and Menges, A. 2010. Material computation in architectural aggregate systems. In Proc. of ACADIA, 372–378.Google Scholar

13. Dorsey, J., and McMillan, L. 1998. Computer graphics and architecture: state of the art and outlook for the future. ACM SIGGRAPH Comput. Graph. 32, 1, 45–48. Google ScholarDigital Library

14. Fairs, M., 2002. Arne quinze at burning man – dezeen. http://www.dezeen.com/2007/05/01/arne-quinze-at-burning-man/.Google Scholar

15. Flagg, M., and Rehg, J. M. 2006. Projector-guided painting. In Proc. of UIST ’06, 235–244. Google ScholarDigital Library

16. Frearson, A., 2014. Chinese company 3d prints 10 buildings in a day using construction waste. http://www.dezeen.com/2014/04/24/chinese-company-3d-prints-buildings-construction-waste/.Google Scholar

17. Jones, B., Sodhi, R., Murdock, M., Mehra, R., Benko, H., Wilson, A., Ofek, E., MacIntyre, B., Raghuvanshi, N., and Shapira, L. 2014. Roomalive: magical experiences enabled by scalable, adaptive projector-camera units. In Proc. of UIST ’14, 637–644. Google ScholarDigital Library

18. Ju, W., Bonanni, L., Fletcher, R., Hurwitz, R., Judd, T., Post, R., Reynolds, M., and Yoon, J. 2002. Origami desk: integrating technological innovation and human-centric design. In Proc. of DIS ’02, 399–405. Google ScholarDigital Library

19. Khoshnevis, B. 2004. Automated construction by contour crafting? related robotics and information technologies. Automation in construction 13, 1, 5–19.Google Scholar

20. Lovatt, A., and Shercliff, H., 2002. Material selection and processing. http://www-materials.eng.cam.ac.uk/mpsite/default.html.Google Scholar

21. Lu, L., Sharf, A., Zhao, H., Wei, Y., Fan, Q., Chen, X., Savoye, Y., Tu, C., Cohen-Or, D., and Chen, B. 2014. Build-to-last: Strength to weight 3d printed objects. ACM Trans. Graph 33, 4, 97. Google ScholarDigital Library

22. Pai, D. K., Doel, K. V. D., James, D. L., Lang, J., Lloyd, J. E., Richmond, J. L., and Yau, S. H. 2001. Scanning physical interaction behavior of 3d objects. In Proc. of SIGGRAPH ’01, 87–96. Google ScholarDigital Library

23. Panozzo, D., Block, P., and Sorkine-Hornung, O. 2013. Designing unreinforced masonry models. ACM Trans. Graph 32, 4, 91. Google ScholarDigital Library

24. Pereira, T., Rusinkiewicz, S., and Matusik, W. 2014. Computational light routing: 3d printed optical fibers for sensing and display. ACM Trans. Graph 33, 3, 24. Google ScholarDigital Library

25. Piper, B., Ratti, C., and Ishii, H. 2002. Illuminating clay: a 3-d tangible interface for landscape analysis. In Proc. of CHI ’02, 355–362. Google ScholarDigital Library

26. Prévost, R., Whiting, E., Lefebvre, S., and Sorkine-Hornung, O. 2013. Make it stand: balancing shapes for 3d fabrication. ACM Trans. Graph 32, 4, 81. Google ScholarDigital Library

27. Raskar, R., Welch, G., and Fuchs, H. 1998. Seamless projection overlaps using image warping and intensity blending. Fourth International Conference on Virtual Systems and Multimedia, Gifu, Japan.Google Scholar

28. Rivers, A., Adams, A., and Durand, F. 2012. Sculpting by numbers. ACM Trans. Graph 31, 6, 157. Google ScholarDigital Library

29. Rivers, A., Moyer, I. E., and Durand, F. 2012. Position-correcting tools for 2d digital fabrication. ACM Trans. Graph 31, 4, 88. Google ScholarDigital Library

30. Skeels, C., and Rehg, J. M. 2007. Shapeshift: A projector-guided sculpture system. In Proc. of UIST ’07 poster session.Google Scholar

31. Sodhi, R., Benko, H., and Wilson, A. 2012. Lightguide: projected visualizations for hand movement guidance. In Proc. of CHI ’12, 179–188. Google ScholarDigital Library

32. Song, P., Fu, C.-W., Goswami, P., Zheng, J., Mitra, N. J., and Cohen-Or, D. 2013. Reciprocal frame structures made easy. ACM Trans. Graph 32, 4, 94. Google ScholarDigital Library

33. Tsai, R. Y. 1987. A versatile camera calibration technique for high-accuracy 3d machine vision metrology using off-the-shelf tv cameras and lenses. Robotics and Automation 3, 4, 323–344.Google ScholarCross Ref

34. Vouga, E., Höbinger, M., Wallner, J., and Pottmann, H. 2012. Design of self-supporting surfaces. ACM Trans. Graph 31, 4, 87. Google ScholarDigital Library

35. Whiting, E., Shin, H., Wang, R., Ochsendorf, J., and Durand, F. 2012. Structural optimization of 3d masonry buildings. ACM Trans. Graph 31, 6, 159. Google ScholarDigital Library

36. Wilson, A., Benko, H., Izadi, S., and Hilliges, O. 2012. Steerable augmented reality with the beamatron. In Proc. of UIST ’12, 413–422. Google ScholarDigital Library

37. Zhou, Q., Panetta, J., and Zorin, D. 2013. Worst-case structural analysis. ACM Trans. Graph 32, 4, 137. Google ScholarDigital Library

38. Zoran, A., Shilkrot, R., and Paradiso, J. 2013. Human-computer interaction for hybrid carving. In Proc. of UIST ’13, 433–440. Google ScholarDigital Library