“Mandible Reconstruction Project” by Grosser

Conference:

- SIGGRAPH 2004 More animation videos from SIGGRAPH 2004:

SIGGRAPH Video Review:

Track:

- 13

Title:

- Mandible Reconstruction Project

Length:

- 2:20

Director(s):

Company / Institution / Agency:

- University of Illinois

Description:

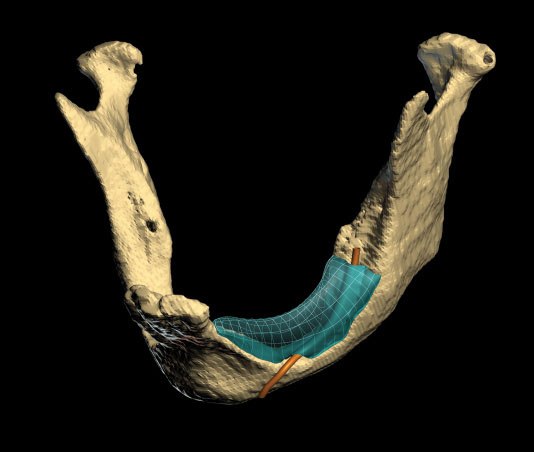

The Mandible Reconstruction Project is an ongoing effort to develop an alternative approach to bone replacement. Using the case of a 73-year-old female who has experienced severe bone loss in the mandible, the multi-disciplinary team created a workflow to design and fabricate a custom artificial bone implant.

The process required extraction of a 3D model of the defect area from the CT scan data so the modelers could work with the surgeon to define and design the implant. Once created, the virtual model was fabricated using a “robocaster” – technology similar to a rapid prototyper, but one which works with custom materials. In this project, the robocaster was used to create structurally strong scaffolds of hydroxyapatite (a substance chemically identical to human bone), from which the implant was milled. During the patient’s autograft procedure, the implant was inserted into the defect and proved a perfect fit.

Since the device was not yet FDA approved, it was removed and used as a template for the bone graft. This first phase of the project demonstrated the feasibility of this approach in a real clinical setting, and the team looks forward to future research.

Hardware:

HARDWARE: Apple G4 dual 1.4 GHz CPUs, Intel Xeon dual 2.8 GHz CPUs, AMD

Athlon dual 2 GHz CPUs; 2-4 GB RAM.

Software:

SOFTWARE DEVELOPER: Modeling: Analyze 6.0 (skull, isolated jaw), Rhinoceros 3.0 (implant),

Maya 5.0 (lattice, cells, other). Animation: Analyze 6.0 (skull anima-

tion), Maya 5.0 (everything else). Rendering: Maya 5.0. Compositing:

Final Cut Pro 4.0. Additional software: Final Cut Pro 4.0, Photoshop

CS. OS: Windows XP, Mac OS X 10.3, Red Hat Linux 9.

Additional Contributors:

Director & Producer: Benjamin Grosser

Contributors: Benjamin Grosser, Carl Burton, Janet Sinn-Hanlon, Russ Jamison, Michael Goldwasser, Joseph Cesarano

Additional Information:

PRODUCTION

Modeling: polygons and subdivision surface. Rendering technique used most: Maya renderer, raytracing. Average CPU time for rendering per frame: 60 seconds. Total production time: eight weeks. Production highlight: The production utilized a scientific analysis and visualization software package called Analyze from the Mayo Clinic to produce the CT scan data-animation sequence and the isolated mandible model. The CT scan was acquired at Carle Hospital (Urbana, Illinois) on a GE Medical Systems Hi CT/i scanner. Development of the implant model was done in consultation with a clinical oral and maxillofacial surgeon to ensure medically acceptable accuracy with the model’s congruence to the existing clinical features in the actual patient.

OTHER

This animation is potentially unique in its combination of medical visualization and analysis software for part of its modeling and animation contents, as well as the ways in which collaborations between researchers in materials science, 3D fabrication, medical illustration, computer modeling, and clinical surgery led to the development of the medically accurate (very high accuracy and/or very low tolerance for error) computer models used in the animation.